Exact MetalsT_Money wrote:Important! I'm starting machining, but where can i get blanks of solid aluminum online cheap? Any help appre.

The Offcial Machinist Thread: Revised 01/04/2014

Here in Massachusetts (US), willing to do some machining (turning/milling), TIG welding, MIG welding, thermoplastic welding, electronics work, woodwork. Machining should be not critical. I can give quotes at tospurr@gmail.com. Am busy, as I'm a full time student (highschool freshman). Decent TIG welder--better than any other 15 year old I know. Reasonable pricing/times.

- jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

Got some Glock 18C rail mounts which turned out to be useless as they were made for non-blowback models we don't stock, a bit of milling and converted them to revolver rails

Yes, I am deeply ashamed that I fitted a suppressor to a revolver, but business is business...

Yes, I am deeply ashamed that I fitted a suppressor to a revolver, but business is business...

hectmarr wrote:You have to make many weapons, because this field is long and short life

- tigerblues28

- Specialist

- Posts: 104

- Joined: Mon Apr 01, 2013 12:56 pm

Damn, that's sexy. I never really pictured a revolver with a red dot sight on it, but a suppressor has been a childhood dream of mine...........*Tear*

Cracking job.

Nick

Cracking job.

Nick

- jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

- Brian the brain

- Moderator

- Posts: 3497

- Joined: Mon Dec 05, 2005 2:06 am

- Location: Holland

- Been thanked: 7 times

I never got why nobody's ever tried putting the cilinder inside of the suppressor tube...

Gun Freak wrote:

Oh my friggin god stop being so awesome, that thing is pure kick ass. Most innovative and creative pneumatic that the files have ever come by!

Can't ask for a better compliment!!

Oh my friggin god stop being so awesome, that thing is pure kick ass. Most innovative and creative pneumatic that the files have ever come by!

Can't ask for a better compliment!!

- jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

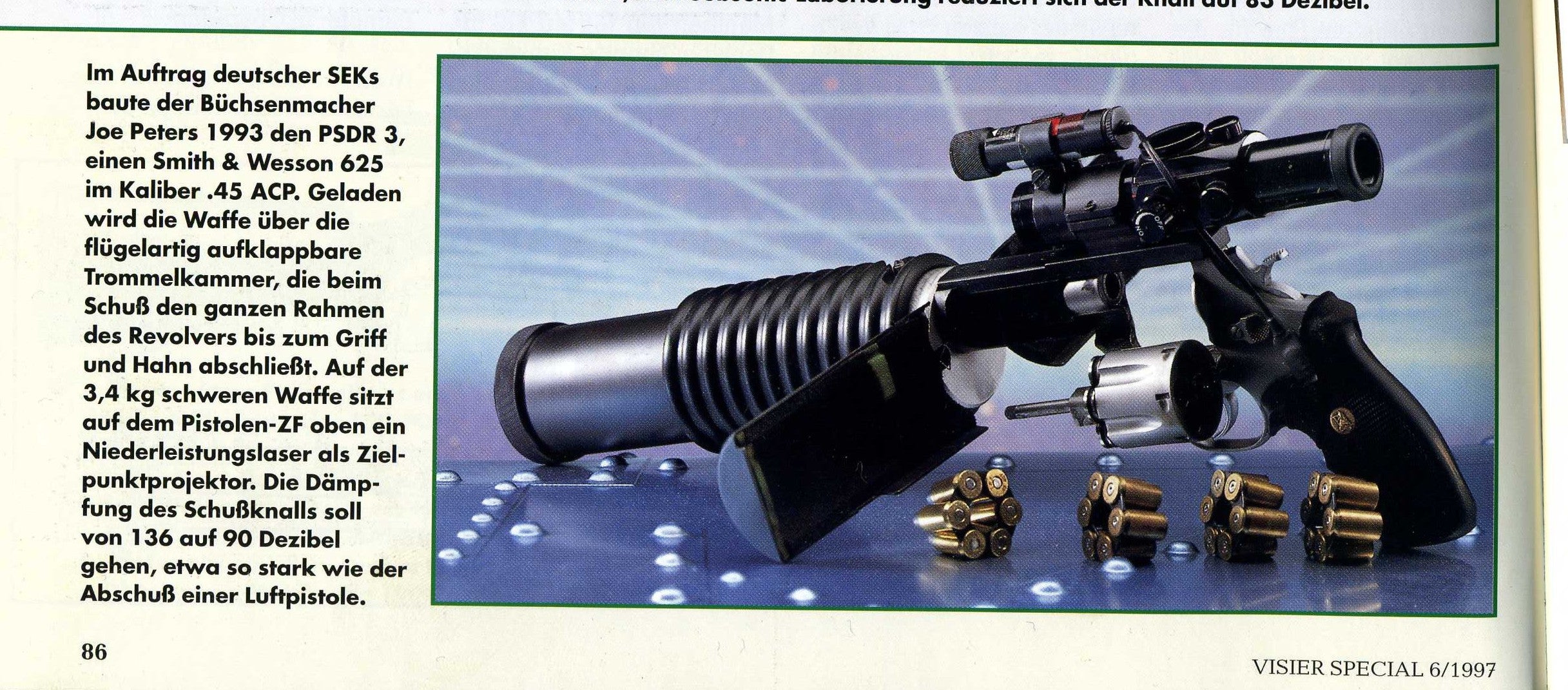

Technically that's what the PDSR-3 does: http://www.cqbservices.com/?page_id=179Brian the brain wrote:I never got why nobody's ever tried putting the cilinder inside of the suppressor tube...

You still need to open it to reload though. An "ingenious solution to a non-existent problem" sums it up pretty nicely.

hectmarr wrote:You have to make many weapons, because this field is long and short life

-

sagthegreat

- Specialist 3

- Posts: 343

- Joined: Thu Feb 16, 2012 5:23 pm

- Location: Leesburg

- Contact:

I need 2 small things machined:

a relible piston with sealing face for my coaxial gun, it will be based in 1/2 inch type m copper pipe

also need something that can center the barrel inside the pipe body without obstructing airflow. The barrel will be normal hobby shop 6mm brass tubing.

I am in america, and have 10 dollars in my paypal account, let me know if that is enough

a relible piston with sealing face for my coaxial gun, it will be based in 1/2 inch type m copper pipe

also need something that can center the barrel inside the pipe body without obstructing airflow. The barrel will be normal hobby shop 6mm brass tubing.

I am in america, and have 10 dollars in my paypal account, let me know if that is enough

sagthegreat, could you put a diagram of the parts needed? I have 1.25 round aluminum and 1.5 round steel. I will not do O-rings however, unless I had the mating pipe in my shop. Got some sheet rubber in the shop too. So only time for me.

I suppose those parts would fit in an envelope, so that would be cheap shipping. Just guessing, but sounds like a 1-2 hour in the shop, 20 min run to the post office/ package it. I'd quote 20 as a high side cause I don't like feeling suckered when like most projects I under estimate the time involved.

I suppose those parts would fit in an envelope, so that would be cheap shipping. Just guessing, but sounds like a 1-2 hour in the shop, 20 min run to the post office/ package it. I'd quote 20 as a high side cause I don't like feeling suckered when like most projects I under estimate the time involved.

-

sagthegreat

- Specialist 3

- Posts: 343

- Joined: Thu Feb 16, 2012 5:23 pm

- Location: Leesburg

- Contact:

I was thinking something light like derlin for the parts as a lighter piston travels faster

the piston is simple round derlin with rubber sealing face

the barrel centering thing is like this:

but a a bit more open to allow more flow

the piston is simple round derlin with rubber sealing face

the barrel centering thing is like this:

but a a bit more open to allow more flow

-

sagthegreat

- Specialist 3

- Posts: 343

- Joined: Thu Feb 16, 2012 5:23 pm

- Location: Leesburg

- Contact:

srry for not reading, here is my pic with dimensions:

its upside down/ ghetto because my computer is on the verge of breaking

(I typed this with a on screen keyboard)

its upside down/ ghetto because my computer is on the verge of breaking

(I typed this with a on screen keyboard)

Last edited by jrrdw on Sat Jan 04, 2014 3:19 pm, edited 1 time in total.

Reason: Added file.

Reason: Added file.

- Labtecpower

- Sergeant 3

- Posts: 1297

- Joined: Sat Feb 20, 2010 6:38 am

- Location: Pyongyang

- Has thanked: 5 times

- Been thanked: 13 times

- jakethebeast

- Corporal 5

- Posts: 945

- Joined: Sat Jul 03, 2010 4:20 pm

- Location: Jakes cave

hehe nice to see you put the slab into good use!

Est Sularus Oth Mithas

- jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

Fantastic work! This Dutch-Finnish co-op thing is going well

hectmarr wrote:You have to make many weapons, because this field is long and short life