Page 1 of 1

etched rifling

Posted: Sun Dec 11, 2011 3:32 pm

by jackssmirkingrevenge

An idea that came from a discussion with Brian that might have some merit - acid etched rifling.

Here's how I see it being done for a short "pistol" type barrel (5" or so):

- drill out tube to just under barrel diameter

- fill with beeswax

- drill out again, 1.5mm or so smaller than tube inner diameter

- cut rifling grooves in the wax (this is the tricky part but there are several options)

- plug one end of the barrel and fill with acid solution

- empty and repeat until the grooves are deep enough

- remove the wax, voila

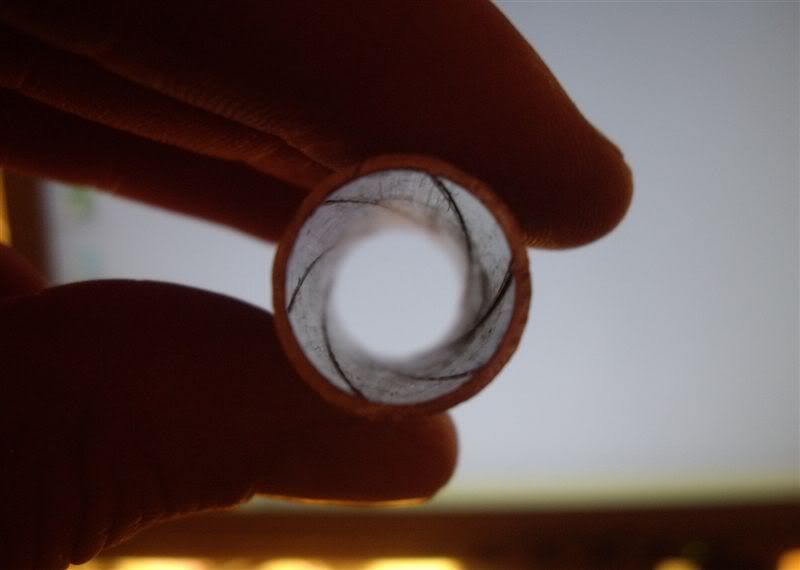

Grooves are still likely to be shallow, so a large number would be necessary to be effective, something like this:

Posted: Sun Dec 11, 2011 3:41 pm

by al-xg

Poor man's electro-erosion eh ?

I reckon I'd be pretty difficult to rifle the wax inside the barrel without breaking it up especially with large numbers of grooves.

Is there not some sort of lacquer one could use for the same effect ?

Mmm and if you've made a rifling tool for wax why not use it directly on the barrel, scratches would be just as effective as shallow rifling, no ?

Does this maybe allow for etching much harder metals too ?

Posted: Sun Dec 11, 2011 4:10 pm

by JDP12

Seems like a ton of work, and when you scratch the pattern in the beeswax you'd have to make sure its perfectly uniform, which would be very hard to do methinks...

While it could be a cool project, although very difficult, why do you need a rifled barrel? A saboted projectile can be extremely accurate as well.. I feel like for our purposes rifling isn't worth it, instead just design a saboted projectile.

Posted: Sun Dec 11, 2011 4:19 pm

by Heimo

another idea:

instead of cutting the rifling pattern in wax, how a bout you coat the inside of the barrel with something like

this then you print your rifling pattern onto a transparency, roll the transparency into a cylinder and insert into a barrel shine a bright light into the barrel this causes the positive 20 to react where it was exposed to the light, then you wash out the exposed positive 20 with a lye solution, and then you can etch....

Posted: Sun Dec 11, 2011 4:45 pm

by SpudBlaster15

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Cras nec placerat erat. Vivamus dapibus egestas nunc, at eleifend neque. Suspendisse potenti. Sed dictum lacus eu nisl pretium vehicula. Ut faucibus hendrerit nisi. Integer ultricies orci eu ultrices malesuada. Fusce id mauris risus. Suspendisse finibus ligula et nisl rutrum efficitur. Vestibulum posuere erat pellentesque ornare venenatis. Integer commodo fermentum tortor in pharetra. Proin scelerisque consectetur posuere. Vestibulum molestie augue ac nibh feugiat scelerisque. Sed aliquet a nunc in mattis.

Posted: Sun Dec 11, 2011 4:57 pm

by jor2daje

JSR could you modify the thread cutting attachment on your lathe to get an incredibly low threads per inch? This could either work for directly boring a rifles or turning grooves into the wax.

Posted: Sun Dec 11, 2011 5:34 pm

by Goats spudz

would this be faster and re-usable

Posted: Sun Dec 11, 2011 5:50 pm

by jackssmirkingrevenge

al-xg wrote:Poor man's electro-erosion eh ?

I reckon I'd be pretty difficult to rifle the wax inside the barrel without breaking it up especially with large numbers of grooves.

Is there not some sort of lacquer one could use for the same effect ?

I've had good results with nail polish...

Mmm and if you've made a rifling tool for wax why not use it directly on the barrel, scratches would be just as effective as shallow rifling, no ?

They need to be fairly deep scratches to be effective...

Does this maybe allow for etching much harder metals too ?

That's the idea.

why do you need a rifled barrel?

More of a "because I can" than "because I need" exercise

instead of cutting the rifling pattern in wax, how a bout you coat the inside of the barrel with something like this then you print your rifling pattern onto a transparency

Sounds a little

too complex...

I don't think this will work very well at all. Coating the surface of the metal with wax will not prevent an acid solution from attacking the underlying material.

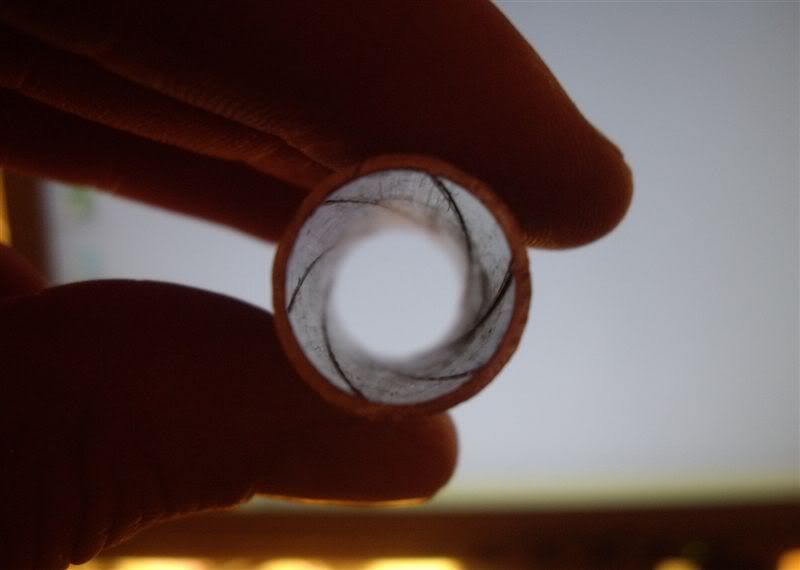

I got some good results with just masking tape

here.

JSR could you modify the thread cutting attachment on your lathe to get an incredibly low threads per inch? This could either work for directly boring a rifles or turning grooves into the wax.

Interesting thought - LeMaudit had written a calculator for it, would be interesting to look into.

Posted: Sun Dec 11, 2011 7:03 pm

by al-xg

It's hard to tell from the picture but how deep are the markings ?

This works well with lead slugs and it's not particularly deep. The main reason is that It'd require a thicker barrel...

Posted: Mon Dec 12, 2011 12:42 am

by jackssmirkingrevenge

Ah yes...

al-xg wrote:This works well with lead slugs and it's not particularly deep. The main reason is that It'd require a thicker barrel...

I don't expect acid to etch much deeper, but surely 12 grooves instead of 6 would be more effective