My dad still has not ordered the lathe and mill yet so I can't get started on my PCP yet but I am very eager to build and shoot an air rifle because I am so bored waiting.

I want to build a coaxial air rifle that is made from aluminum. This gun will be made for pure accuracy and hopefully be able to shoot 2 inch groups at 125 meters max. The gun will be pressurized to 100 psi - 150 psi. Any higher pressure than this will be too loud. (And of course I'll build a silencer for it.)

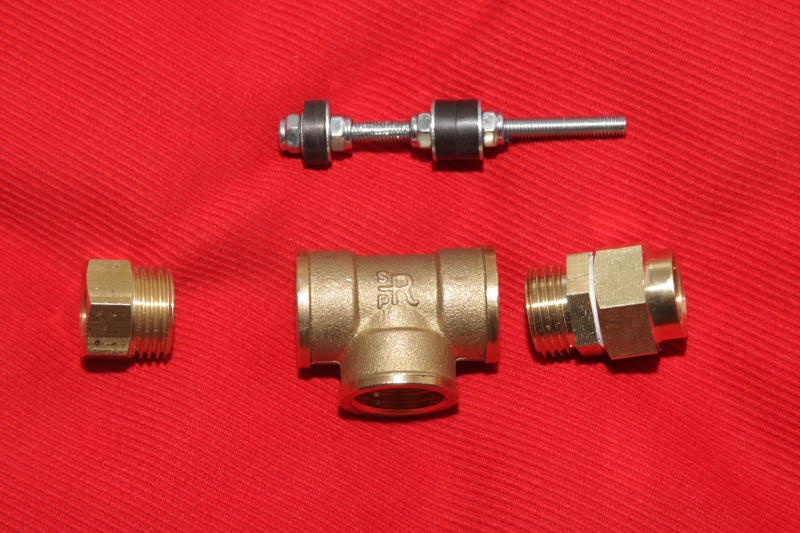

I also want this gun to look nice and I'll make a nice stock for it as well. So for a pilot I would like to use a schrader valve. I'm thinking of using a 1/2" aluminum pipe for the outer body and a 8mm aluminum pipe for the barrel. The whole gun is planed to be 70cm long total but the pressure chamber will be cut off half way down the barrel because the gun is so long that the air right at the end of the gun will never reach the projectile in time to benefit it and it will slow down recharging. So my first question is, will the schrader valve be big enough to pilot the gun?

Secondly, because this gun will be used at 150 psi maximum, I want to use an aluminum dowel that will fit snugly inside the 1/2" pipe and use that as end plugs which I will epoxy in. So my second question is: Will epoxy safely hold 150psi?

I was thinking of ways to reduce sound as much as I can. So I thought of using a spring with some rubber on the end of it behind the piston to act as a bumper and absorb impact sound and prevent damage to the gun.

I will design a projectile that will be accurate and create it on the lathe, for now I will use darts because I don't have the lathe yet.

Please don't be mistaken, I will be building that PCP I have been designing but I can't because I haven't got my machinery yet, for now I'm building this for recreational purposes.

All help is greatly appreciated.