this is the air gun i would like to replicate ( there was some one else that was doing the same ?? )

isn't it pretty !.....

I dont know where im going to get a .22 barrel from, maybe theres copper or brass tubing to same size, but then i would only get smooth bore, unless i rifle it....

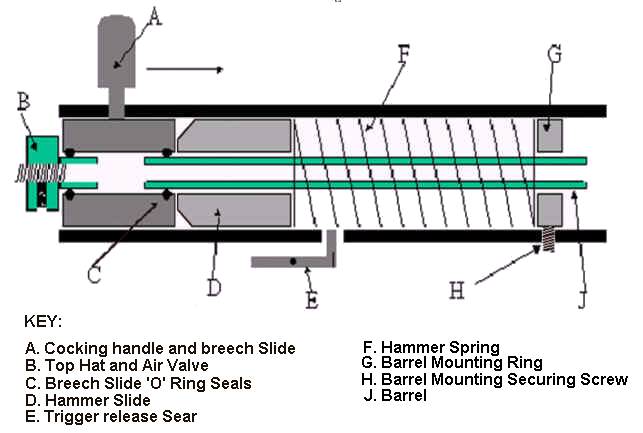

Heres how the breech works on it

I intend on getting access to my grandads metal lathe or even moving it round to my place for the time being. so machining shouldnt be a problem.

Any way tell me what you think and tips or what not.

EDIT : Oh and my tank is and old dry powder fire extinguisher tank, and one know what pressure thats rated for please ?..... Im probably only going to be running this thing at 300-500 psi if my tank allows it, i think 3000psi is a bit much for me ( 15 )

Barrel size: 9.53 x 2.03 SMT ( Seamless Mechanical Tube ) this is for a .22lr Same as a .22 pellet ( hopefully ) im gonna have to find some one this stuff.

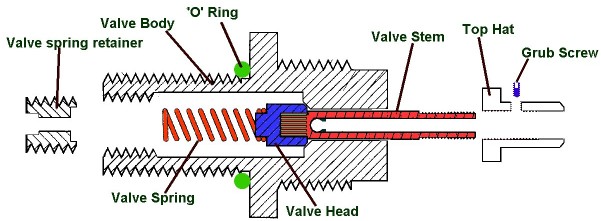

Heres a couple of pics of my high pressure hammer valve. I based it on the valve on instructables and the original one from the airforce air guns. Its made from Brass, and aluminum tube, O-ring and a spring from quick connect airfitting. by rights this should hold a lot of pressure, maybe around 500psi......