Page 1 of 2

hammer valve auto idea

Posted: Mon Dec 31, 2007 7:53 am

by jackssmirkingrevenge

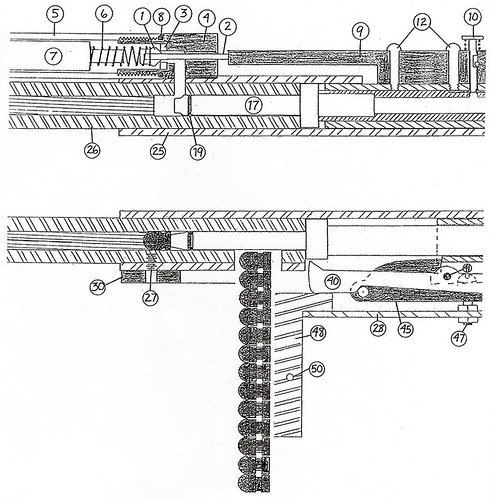

A while ago I came up with a

design that used an electric motor to cock a hammer valve that basically consisted of the barrel itself. looking at it, it would probably work just as well without the motor, though you'd need to add a latch that would hold the barrel in the cocked position.

It's fairly straightforward, the diagram shows the mechanism at rest. To fire, the purple barrle section is pulled to the left, this compresses the spring and allows a projectile to drop through the ammunition slot. The barrel is then released and moves to the right, sealing the ammunition slot, and knocks open the red valve. This allows compressed air to escape through the air slots, firing the projectile, as well as pushing the barrel back forward in order to enable the sequence to restart.

No plans to build this as of yet, just thought i'd share the idea.

Posted: Mon Dec 31, 2007 9:12 am

by bluerussetboy

were you shooting for auto or semi-auto?

if auto, i would think the rof would not be that good. how fast would it take for the air pressure to drop to the point of not resetting the barrel far enough to open the hammer valve?

if just semi, i could see using a cam to cock the barrel.

two of these side by side with a cam setup for fire control would give this the AT-AT feel.

Posted: Mon Dec 31, 2007 9:15 am

by jean

hi

mh this is the same design what ant use in the bb-gun i think...

here pic to show my version of valve is much easier

i fit it to an cap of plastic bottle

Posted: Mon Dec 31, 2007 10:40 am

by Hawkeye

Looks almost identical to what ant made.

Posted: Tue Jan 01, 2008 11:39 pm

by jackssmirkingrevenge

Hawkeye wrote:Looks almost identical to what ant made.

So it is, I hadn't seen his

diagram.

Ah well, I had posted the original electric driven version

here (scroll to the bottom) in August so it's a case of great minds think alike

Posted: Wed Jan 02, 2008 1:09 am

by TwitchTheAussie

Ah its all good jack

. Youll have another flash of inspiration soon

Posted: Wed Jan 02, 2008 2:25 am

by jackssmirkingrevenge

I'm actually quite liking the idea of a hammer powered valve, I've been looking at the

Caselman in more detail to see if something conceptually similar could be scaled up to a larger calibre and lower pressures.

Posted: Wed Jan 02, 2008 7:23 am

by jackssmirkingrevenge

Ok, now things are getting a bit complicated, I'm straying somewhat from my "keep it simple" brief...

Posted: Wed Jan 02, 2008 8:41 am

by Skywalker

JSR, how's that any different from a normal hammer valve gun, like most bb guns? I guess the hammer orientation is one thing, and the sliding breach is another, but am I missing something? Is the hammer supposed to c0ck itself? That's quite similar to my auto-hammer idea, which I've got some revized ideas for. I need to go draw them up.

Posted: Wed Jan 02, 2008 8:51 am

by jackssmirkingrevenge

how's that any different from a normal hammer valve gun, like most bb guns?

In normal BB guns, the hammer is manually cocked for every shot. In this case, the air has to first push the piston (which in this case acts as the hammer) back and recock the system before it can escape through the breech. I wouldn't be surprised if similar designs have been submitted before as it's a fairly "logical" solution using well established parts.

Posted: Wed Jan 02, 2008 9:18 am

by Tsukiten

Do you think this would work with any kind of pressure? All the springs and stuff might require tons of psi...

Posted: Wed Jan 02, 2008 9:20 am

by Skywalker

You're right, it *is* the logical next step. I wonder if a commercial CO2 pellet/bb gun could be hacked to work that way? Does the caselman work that way? I can't understand those diagrams.

Posted: Wed Jan 02, 2008 9:28 am

by jackssmirkingrevenge

Tsukiten wrote:Do you think this would work with any kind of pressure?

There will be an optimum pressure of course below which the hammer will not be cocked.

Does the caselman work that way? I can't understand those diagrams.

The hammer (9) strikes the valve stem (2) which allows a burst of air into the barrel between the projectile and the bolt (17) - this fires the projectile and pushes the bolt back, recocking the hammer and allowing the cycle to continue, unless the bolt is caught by the trigger sear.

Posted: Thu Jun 12, 2008 7:51 am

by Antonio

oh here it is. Jack I posted in your previous

http://www.spudfiles.com/forums/making- ... rt,90.html post if this conept worked? As I said, I dont get enough air once the piston has reached the barrel port. I dont really get why the caselman concept recocks, I guess it must be the heavier projectile and the higher opperating pressure. After all the force that the air applies on the bullet is the same that is applied to the bolt.

Posted: Thu Jun 12, 2008 9:23 am

by jackssmirkingrevenge

ant wrote:I dont really get why the caselman concept recocks, I guess it must be the heavier projectile and the higher opperating pressure. After all the force that the air applies on the bullet is the same that is applied to the bolt.

That's exactly the point - the Caselman is working with thousands of psi, so direct air pressure on the bolt face that's the same diameter as the barrel is sufficient to cycle the action. We're working with less than 10% of the pressures here, meaning that route is unavailable to us.

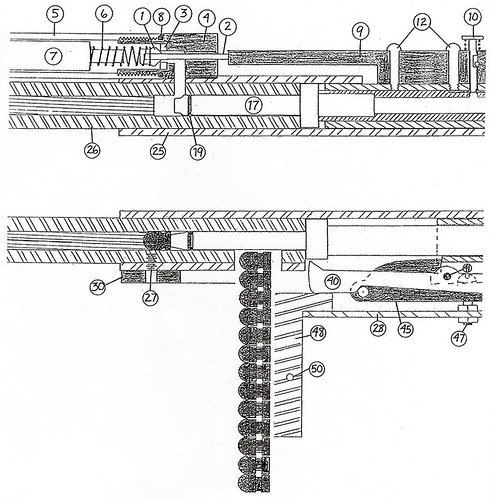

What we can do is give the bolt a larger area, and there are several ways of doing this. Here's

one I had come up with - similar to some painball designs - but never built:

I had also made an attempt at a simple Caselman style

direct blowback design (originally intended to be electrically driven) but it failed for the same reasons, I had though of a way of solving the problem by applying the same larger bolt area rule, but never actually built it:

Now I'm in the mood to build, but there's not much i can do from here in Spain - still, I got my hands on some piping from the maintenance department, now to find some

resina epóxica 'cause one needs a pneumatic around the house *evil cackle*