Page 1 of 1

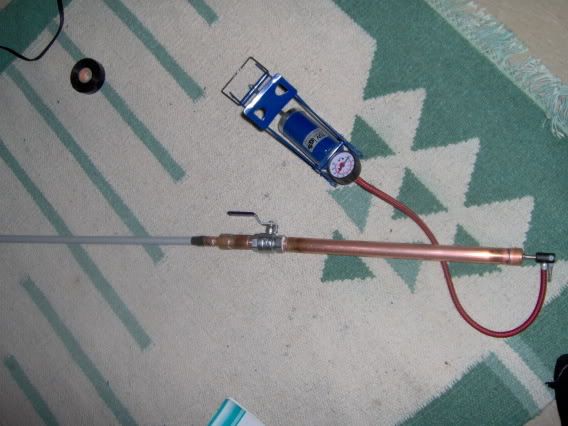

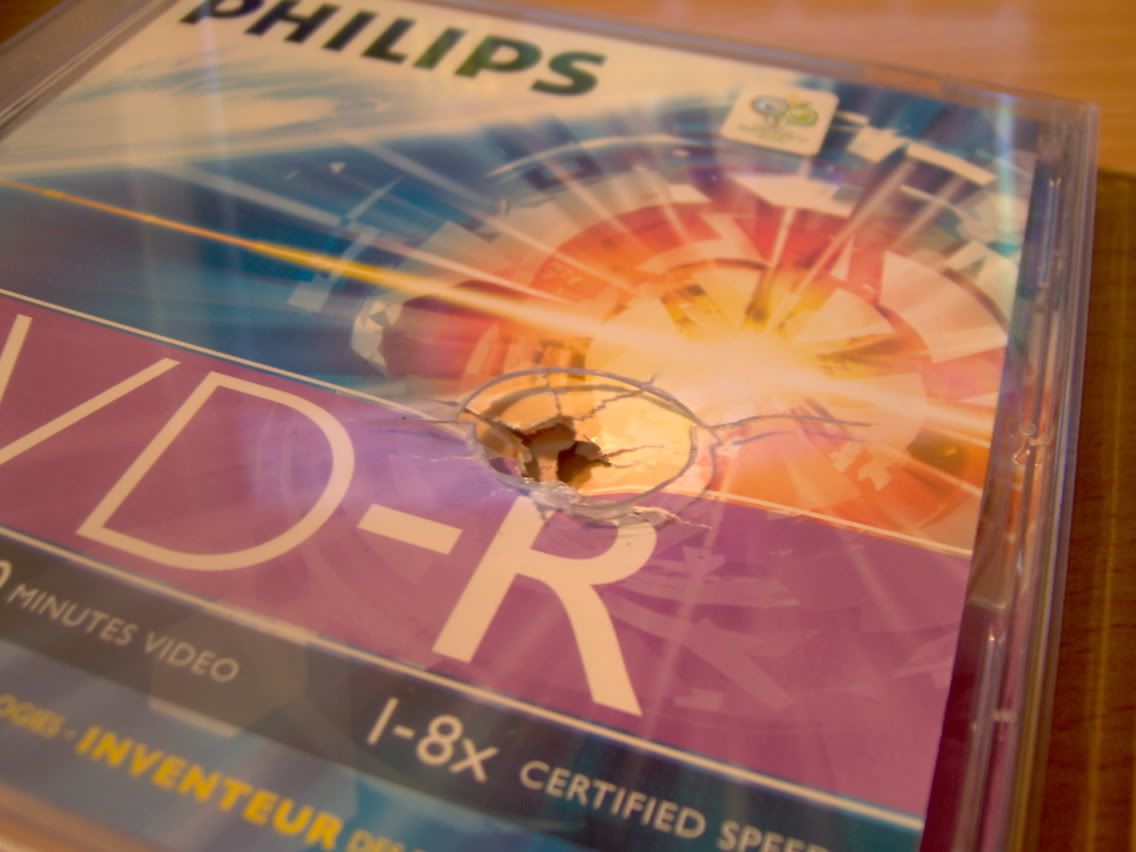

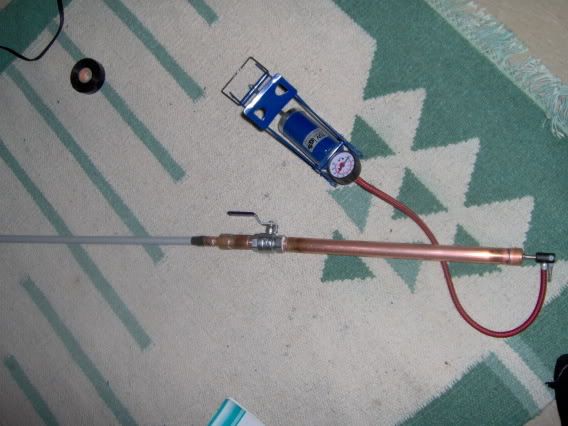

My new simple copper marble gun

Posted: Tue May 02, 2006 8:53 am

by shockwave

After messing with PP plastic I finaly desided to go for copper pipes instead (PVC is quite uncommon here). I used 40 mm long, 28mm diameter pipe for the chamber and 15mm for the barrel. The valve is ordinary ball valve. My next design is gonna utilise the sprincler valve i got on my PP cannon =)

At 100psi I can blow a clean hole in a telephone catalog through about 200 pages. I havent done many tests on other things yet but I'll post pics as soon as I have done that

I'm going to try higher pressures when I get my mini compressor working. I hope welds will hold. They seem to be good becouse everything went as planned when welding - the solder got sucked into the joint just fine =)

EDIT: oh and luckely AA batteries happen to be allmost 15mm diameter making them great ammo

Posted: Tue May 02, 2006 9:00 am

by x.X.Cpt.Rollhart.X.x

I'll try to make one tonight

Wich part did you weld ?

Posted: Tue May 02, 2006 9:55 am

by rna_duelers

Nice,there isnt enough copper guns and this one is simple but nice and the solders should hold the pressure.And x.X.Cpt.Rollhart.X.x he solderd the joints of the copper so they dont come apart.

Posted: Tue May 02, 2006 10:25 am

by shockwave

The barrel joint is the only silly one. Copper pipes are expensive so I used an other one and it was too thin for the muff so I put some tape around it

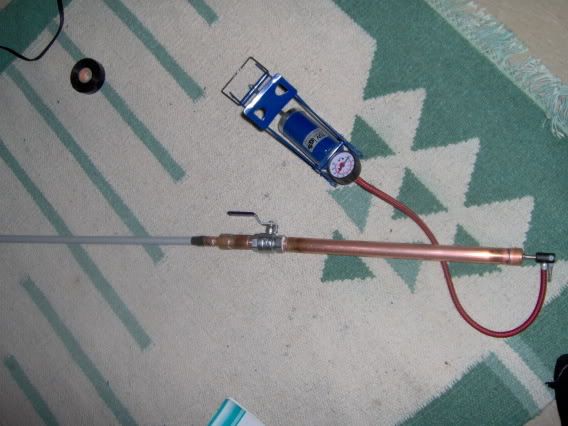

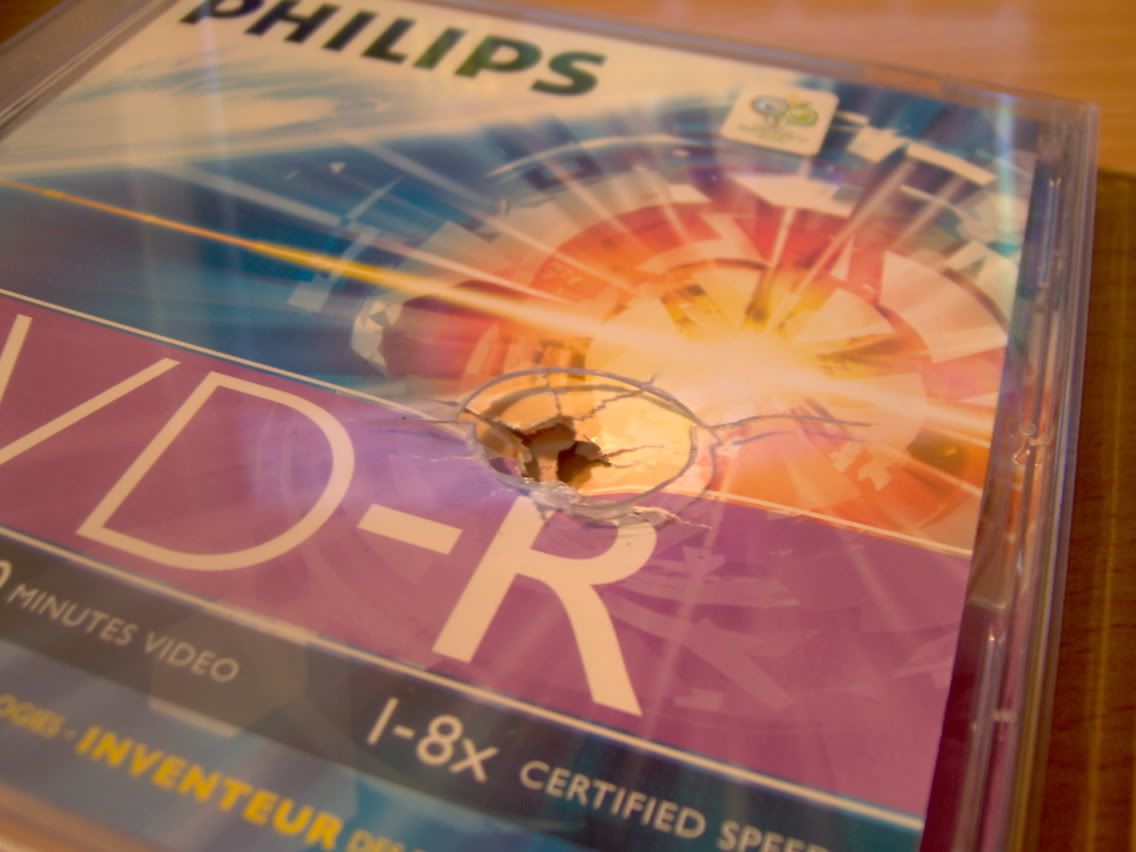

It's no big deal though since that part is not pressurised for longer periods of time. At first I was quite disappointed when I tested this cannon couse it just spat the marble out and it roled on the floor. Then I attached the valve to a drill and let it spin for a few seconds. After that the valve was much easier to open so I could then open it much faster. I did a few tests and discovered that it wasnt much of a difference between using a sprinkler valve and a ball valve. The only con is that you cant aim when you use a ball valve. Here are a few damage shots at 100psi with a marble:

Obviosly it went right through, spreading tiny pieces of plastic all over my bed

This is a hard drive disc. They are made of copper, are 1mm thick and are quite hard to bend with bare fingers. Even though the marble didn't go all the way through, it still left a nice buckle on the disc.

A coin. It's realy hard to aim, I was aiming for the middle from 2cm distance =/

Posted: Tue May 02, 2006 11:51 am

by Rambo

How did you weld the parts together?Did you use a propane/air flame or O2 is neded?

Posted: Tue May 02, 2006 12:31 pm

by shockwave

I used propane torch, liquid flux and tin-silver solder.

Posted: Tue May 02, 2006 12:53 pm

by rna_duelers

It can be done without the O2 just a plain propane torch,the melting point of copper is around 1000C and a propane torch can get to 1300C and solder melts at 180C so it would work.

Posted: Wed May 03, 2006 9:24 am

by shockwave

man it scary shit to shoot plastic pens at a wall... one bounced off two walls in a corner and allmost hit me

I'm going to try higher pressures when I get my mini compressor working. I hope welds will hold. They seem to be good becouse everything went as planned when welding - the solder got sucked into the joint just fine =)

I'm going to try higher pressures when I get my mini compressor working. I hope welds will hold. They seem to be good becouse everything went as planned when welding - the solder got sucked into the joint just fine =)