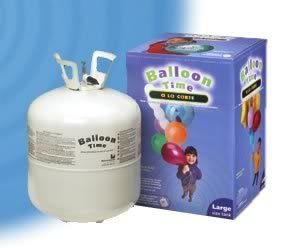

As the topic suggests, I recently acquired a small helium tank about the size of a gas grill propane tank at a "party" - they would've just thrown it away, so I got it for free. From what I can tell this thing is pretty thin, but the remaining helium shows up as 60 psi. It speceficially says not to re fill it, but I personally see no harm as long as I keep it at or below 100 PSI.

My question is: Is this thing safe to use? No ridiculously high pressures, just that 100 PSI, but the construction seems rather light. I realize that it still has a whole buncha helium left which could make it seem wimpier, but regardless, its kinda sketchy. Theres a welding seem around the circumference, and what seems like a welded shut hole on the top, so if something horrible happens theres a weak point so that it may split rather than frag.

I plan to use this thing for a small BBMG turret I'm making for use in airsoft, so the relatively small size is not much of a concern. I'd love to use this, so any feedback would be appreciated

Helium Baloon Tank?

Pictures would probably help a lot. Plus I want to see it

- Zippster

- Private 4

- Posts: 80

- Joined: Sun Sep 30, 2007 8:57 pm

- Location: Austin, Texas - you'd better believe it

Same one, 'cept mine's pink

I'm not using their crappy valve - I've teflon'ed and clamped on a hose leading to a gauge and quick-connect

At this point I feel quite comfortable with it, but would still like y'alls opinions

Proud to be the only kid on my robotics team with pneumatics experience.

- MrCrowley

- Moderator

- Posts: 10078

- Joined: Fri Jun 23, 2006 10:42 pm

- Location: Auckland, New Zealand

- Been thanked: 3 times

Even the thin aluminium fire extinguishers handle 300psi, so you should be fine with 100psi.

The valve internals would probably fail first anyway, so if you're not using the valve you'll be fine.

The valve internals would probably fail first anyway, so if you're not using the valve you'll be fine.

those helium tanks are made from the same exact material as propane tanks. I modified an old propane tank a while back for a science project and taken it up to 484psi before it started to leak. didn't get to find out exploding pressure because the compressor only went to 500psi.

So anything under 350psi, or even 400psi, should be golden

So anything under 350psi, or even 400psi, should be golden

Forum Rules - follow them or else!

“Happiness is the meaning and the purpose of life, the whole aim and end of human existence”

“Happiness is the meaning and the purpose of life, the whole aim and end of human existence”

That is most likely why it only asks you to never refill, because the valve is only meant to let out air, not refill it with that valve.MrCrowley wrote:The valve internals would probably fail first anyway, so if you're not using the valve you'll be fine.

Last edited by SpudUke5 on Sun May 25, 2008 8:33 pm, edited 1 time in total.

4SPC, My 4" piston 3" porting cannon

Memo:

Fix up copper cannon

Fix up 4SPC

Start Stirrup pump

Start Toolies piston bazooka

Memo:

Fix up copper cannon

Fix up 4SPC

Start Stirrup pump

Start Toolies piston bazooka

- Zippster

- Private 4

- Posts: 80

- Joined: Sun Sep 30, 2007 8:57 pm

- Location: Austin, Texas - you'd better believe it

I still use their gate valve (its welded on) but I abandoned that crappy balloon filler thing a long time ago. Thanks for the help then, I feel a lot safer now that 5 random people whom I met on the internet assure me that its safe  , but honestly I appreciate it

, but honestly I appreciate it

Proud to be the only kid on my robotics team with pneumatics experience.

if you are here( on the forum) then why are you worried about what the manufacture says "do not refill"

yea and pvc pipe manufacture's tell you how to build cannons out of their pipe..

if you question it then don't do it.....and don't be shock if/when something goes wrong

yea and pvc pipe manufacture's tell you how to build cannons out of their pipe..

if you question it then don't do it.....and don't be shock if/when something goes wrong

Pink? Nice color for a cannon partZippster wrote:<image>

Same one, 'cept mine's pink

I'm not using their crappy valve - I've teflon'ed and clamped on a hose leading to a gauge and quick-connect

At this point I feel quite comfortable with it, but would still like y'alls opinions

Telfon'ed? Why? Did you teflon the thing where you clamped the hose on?

Remember telfon does not seal, it lubes, meaning you can harder twist in threaded stuff. Do not teflon hose connectors, ever.

- potatoflinger

- Sergeant 2

- Posts: 1136

- Joined: Thu Nov 02, 2006 3:26 pm

- Location: Maryland

I think he meant the threaded hose connectors, not a hose barb.psycix wrote: Telfon'ed? Why? Did you teflon the thing where you clamped the hose on?

Remember telfon does not seal, it lubes, meaning you can harder twist in threaded stuff. Do not teflon hose connectors, ever.

It's hard to soar with eagles when you're working with turkeys.

- Zippster

- Private 4

- Posts: 80

- Joined: Sun Sep 30, 2007 8:57 pm

- Location: Austin, Texas - you'd better believe it

Yeah, the only part to clamp it on was a threaded piece which wasn't compatible with anything I could find, and no matter how hard I tried, it wouldnt seal. I figured the problem was air running straight up the threads, so to fix it I teflon'ed it up a lot and viola it sealed.

Proud to be the only kid on my robotics team with pneumatics experience.

Oh ok then.

Good luck. Dont forget to show it to us when its in use

Good luck. Dont forget to show it to us when its in use

Create an account or sign in to join the discussion

You need to be a member in order to post a reply

Create an account

Not a member? register to join our community

Members can start their own topics & subscribe to topics

It’s free and only takes a minute

Sign in

-

- Similar Topics

- Replies

- Views

- Last post

-

- 10 Replies

- 2679 Views

-

Last post by D_Hall

-

- 4 Replies

- 5910 Views

-

Last post by Technician1002

-

- 27 Replies

- 5241 Views

-

Last post by Lentamentalisk

-

- 28 Replies

- 13231 Views

-

Last post by jackssmirkingrevenge

-

- 13 Replies

- 3858 Views

-

Last post by Insomniac