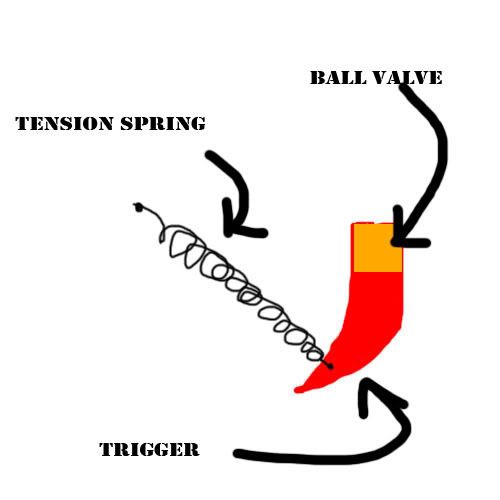

I have a 1/2 inch ball valve that I have fixed to an aluminium plate.

I want to make it spring loaded with tension springs but do not know how to go about doing this.

I would like to include a trigger in the design as it is going to be an exhaust valve. I need some help with making this.

Spring loaded ball valve design

Put a bolt or something sticking out of the piece of metal just to the left of the trigger in my diagram so that when it is pulled that way buy the spring it stops on the bolt so then it is closed. when you pull it it opens and well... yeah.

- Brian the brain

- Moderator

- Posts: 3497

- Joined: Mon Dec 05, 2005 2:06 am

- Location: Holland

- Been thanked: 7 times

The only hard thing is you'll have to make a squared hole to grip the "axle"of the ballvalve.

Just drill a smaller hole and file away.Or you can leave the handle and attach a plate to it in the shape you have drawn

The drawing should work, but I would put the pivot point of the trigger a little lower.

it should be straight from the point where the trigger meets the "hammer"plate like so -> I------0

Just drill a smaller hole and file away.Or you can leave the handle and attach a plate to it in the shape you have drawn

The drawing should work, but I would put the pivot point of the trigger a little lower.

it should be straight from the point where the trigger meets the "hammer"plate like so -> I------0

Gun Freak wrote:

Oh my friggin god stop being so awesome, that thing is pure kick ass. Most innovative and creative pneumatic that the files have ever come by!

Can't ask for a better compliment!!

Oh my friggin god stop being so awesome, that thing is pure kick ass. Most innovative and creative pneumatic that the files have ever come by!

Can't ask for a better compliment!!

- Brian the brain

- Moderator

- Posts: 3497

- Joined: Mon Dec 05, 2005 2:06 am

- Location: Holland

- Been thanked: 7 times

so the trigger can't slide off the hammer part.

Gun Freak wrote:

Oh my friggin god stop being so awesome, that thing is pure kick ass. Most innovative and creative pneumatic that the files have ever come by!

Can't ask for a better compliment!!

Oh my friggin god stop being so awesome, that thing is pure kick ass. Most innovative and creative pneumatic that the files have ever come by!

Can't ask for a better compliment!!

Create an account or sign in to join the discussion

You need to be a member in order to post a reply

Create an account

Not a member? register to join our community

Members can start their own topics & subscribe to topics

It’s free and only takes a minute

Sign in

-

- Similar Topics

- Replies

- Views

- Last post

-

- 32 Replies

- 14367 Views

-

Last post by Technician1002

-

- 18 Replies

- 5244 Views

-

Last post by jhalek90

-

- 2 Replies

- 979 Views

-

Last post by watto

-

- 14 Replies

- 3911 Views

-

Last post by Hawkeye

-

- 4 Replies

- 4057 Views

-

Last post by jackssmirkingrevenge