Page 9 of 15

Posted: Thu Jun 02, 2011 5:25 am

by jackssmirkingrevenge

Added Walnut grips and everything

"useful" is relative...

Posted: Thu Jun 02, 2011 6:01 am

by al-xg

"useful" is relative...

Well of course, or no one would even use this forum. But even at 850psi that 1mm bore cartridge surely won't satisfy your usual biscuit tin smiley face penetration test ?

I'm guessing this is all for a miniature contraption, but isn't that sidetracking on world domination ?

Don't start making rubber band guns

Clockwork birds made of gold though...

I must admit at times I have thought of making a miniature artillery piece.

Posted: Thu Jun 02, 2011 6:23 am

by jackssmirkingrevenge

al-xg wrote:I'm guessing this is all for a miniature contraption, but isn't that sidetracking on world domination?

Lateral thinking, my friend - not directly useful for world domination, but potentially useful practice while creating the sort of tiny artefact the ownership of which certain individuals are willing to part with considerable sums for, something I'm becoming increasingly conscious of.

Posted: Thu Jun 02, 2011 8:16 am

by al-xg

It is that clockwork birds fault then after all

Posted: Thu Jun 02, 2011 2:22 pm

by Labtecpower

I would love to see a nice pneumatic handgun from you

why not try to make an on-board fueling system, with a butane canister in the grip and a venturi inlet to the pump?

With a small diameter pump like that you have the possibility to reach high mixes

Just find a way to make a reliable ignition system that's not too bulky.

Posted: Thu Jun 02, 2011 3:00 pm

by warhead052

shiny455 wrote:are you really going to hold 100psi with some duct taped broken pvc pipe

No I am not, I am just saying.

Posted: Thu Jun 02, 2011 7:10 pm

by jackssmirkingrevenge

al-xg wrote:It is that clockwork birds fault then after all

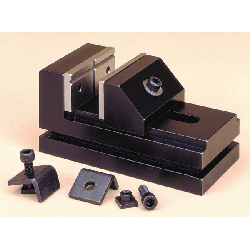

No, it's this mystery object that changed it all:

I would love to see a nice pneumatic handgun from you

If all goes well you should be seeing that and much, much more

Just find a way to make a reliable ignition system that's not too bulky.

A piezo is good enough for a mini but only for 16x or so. What might do the trick is hot wire ignition, the capability of making small cartridges with say threaded bases to make the wire replaceable for every shot would be an asset, especially because it avoids the hassle of heavily insulating high voltage wires.

edit: mini gatling springer, hmm...

Posted: Fri Jun 10, 2011 5:41 am

by jackssmirkingrevenge

Posted: Fri Jun 10, 2011 5:48 am

by POLAND_SPUD

Posted: Fri Jun 10, 2011 5:51 am

by jackssmirkingrevenge

I should be more like this:

It's his fault, whether he admits it or not!

Posted: Fri Jun 10, 2011 5:59 am

by POLAND_SPUD

It's his fault, whether he admits it or not!

so he lent you a hand, right ?

Now this is getting weird

anyway how much did that cost?

Posted: Fri Jun 10, 2011 6:05 am

by jackssmirkingrevenge

LOL!

Including shipping and import duty it's going to total around $2500, plus another $100 or so spend on drills, tap/dies etc. but my consultant assures me I will have all I need.

You know, I'm probably not buying the Merkur set we had been discussing now...

Posted: Fri Jun 10, 2011 6:07 am

by POLAND_SPUD

You know, I'm probably not buying the Merkur set we had been discussing now

heh can't blame you - soon you can start making your own meccano parts

Posted: Fri Jun 10, 2011 6:07 am

by Zeus

Ah, Sherline mini lathe and mill? Why didn't you get the CNC setup?

I'm glad to see you got the 8 axis mill head and rotating table. Stuff thre dimensions, you'll have 9 axis and the lathe.

That setup with the CNC is my eventual goal, I just need around $6000USD. It shall be a while.

Edit: Need sarcasm tags on

Why didn't you get the CNC setup?

. It didn't really convey properly.

Posted: Fri Jun 10, 2011 6:18 am

by LeMaudit

It's his fault, whether he admits it or not!

I deny everything... just in case!

Ah, Sherline mini lathe and mill? Why didn't you get the CNC setup?

I just need around $6000USD.

Here you answer your own question

The beauty of Sherline equiment is that you can go step by step... from a lathe + a milling column to a lathe + a separate mill to a full CNC equipment!

And without never loosing money because you can reuse almost all the accessories... and resell the left over (like say, the wheels when you go CNC) on eBay for fair prices.