Page 2 of 2

Posted: Mon Oct 22, 2007 6:51 pm

by HaiThar

My cylinders have come! Pictures are attatched. In response to Marco:

Yes, I do plan to have the rotational movement controlled by a DC motor. I just don't know how to make a gear box, and all the neccessary equipment....If you don't mind posting the pictures, I would really appreciate it.

So I've decided AGAIN to change the design. One cylinder will be at the back of the barrel, one will be at the front. I figure, It can acheive the same results.... I need now, a regulator, 2 sprinkler valves, a three way valve, and I need to build the housings and tank.

Posted: Mon Oct 22, 2007 7:24 pm

by Marco321

Its looking good!

Here is the gearbox, its a simple design, just th cogs will be hard to make or find. The design simply takes the speed of the motor and converts it using cogs to turn an axle slower, but with much more torque.

Posted: Wed Oct 24, 2007 7:17 pm

by HaiThar

Yeah, that does look a little harder to build.... =P

If I were to buy a high-torque DC motor, do you have any idea on how I would be able to attatch it to the barrel?

Posted: Wed Oct 24, 2007 8:11 pm

by Marco321

HaiThar wrote:Yeah, that does look a little harder to build.... =P

If I were to buy a high-torque DC motor, do you have any idea on how I would be able to attatch it to the barrel?

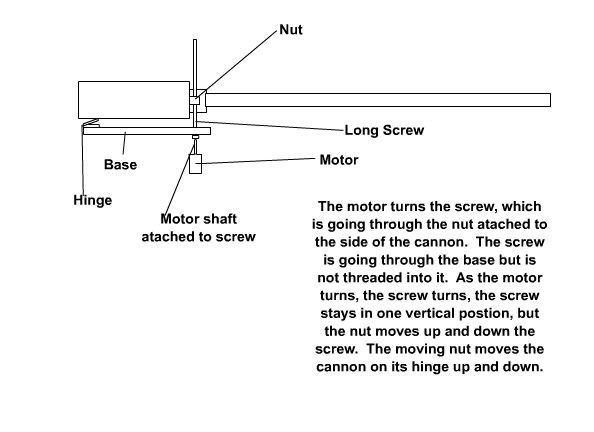

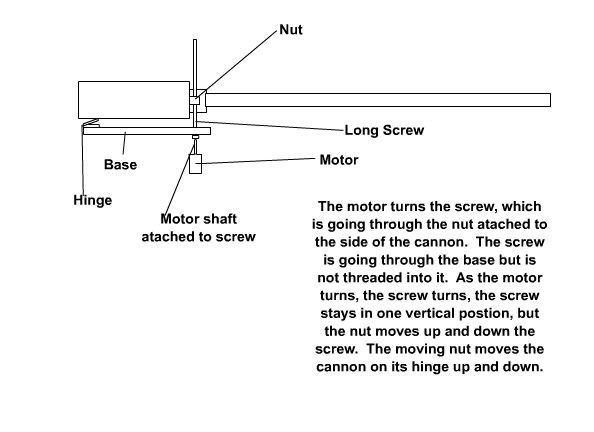

Here is a design that doesn't rely on a gear box. The screw can be one of those long threaded rods you buy from hardware shops.

Posted: Wed Oct 24, 2007 9:07 pm

by HaiThar

That would actually be perfect for the horizontal movement... I already had the vertical movement down with the cylinders, but that is really a great idea....

Any idea on how I could attatch the screw to the motor shaft?

Posted: Wed Oct 24, 2007 9:11 pm

by Marco321

HaiThar wrote:That would actually be perfect for the horizontal movement... I already had the vertical movement down with the cylinders, but that is really a great idea....

Any idea on how I could attatch the screw to the motor shaft?

Oh right lol, well as long as it helped

Depends how thick the motor shaft is, maybe some metal epoxy putty if there is enough surface area on the motor shaft available. Thats my best idea i can think of, but a weld would be ideal. Maybe if you got 2 evenly sized cogs onto the shaft and onto the screw.

EDIT: Get your hands on this, it has a thread and will have some decent torque

Elctric Motor Gear Box

Posted: Thu Oct 25, 2007 5:53 pm

by HaiThar

Bah, I haven't got any cash at the moment. I just won $50 on that EBay shop victoriously thing though, so if that cash gets credited soon enough, I will get it....

Anyway, yeah, that looks just perfect for what I need it for...even comes with a knut!

Anyway....

How do you think I should do this? Maybe have it on a track?

I am having trouble visualizing how it's going to happen...

Posted: Thu Oct 25, 2007 6:28 pm

by Marco321

HaiThar wrote:

How do you think I should do this? Maybe have it on a track?

I am having trouble visualizing how it's going to happen...

How whats going to happen?

Posted: Fri Oct 26, 2007 12:11 am

by HaiThar

How it will move horizontally. I.E. how the set up will be.