Page 2 of 2

Posted: Tue Oct 23, 2007 4:00 am

by Redcoat

I've wanted to do a minigun for a while myself. If you do you will most likely still find it hard to match the ROF of an inline vortex. A minigun Would be good. I have plans for one though I know i will probably never build it.

Other than that, go for the obvious have four inlines all attached to the one gun and have them going at the same time

. Your either going to need four different compressors or one helluva big one. It would be worth it though.

Good Luck!

Happy Spuddin'

Posted: Tue Oct 23, 2007 10:19 am

by BC Pneumatics

Novacastrian wrote:What pressures can commercial valves go to?

You can buy valves rated well past 3500psi.

This would be the only limiting factor, no?

If you use a metal ball valve, this is usually the strongest part.

Posted: Tue Oct 23, 2007 11:50 am

by jimmy101

The limiting factor really isn't the pressure, it is the air flow rate and the resulting pressure drop.

If you could actually get 120 PSI behind a BB in a BBMG you would get muzzle velocities much higher than 300~350 FPS the typical BBMG gets.

Folks have figured it out before, the typicall BBMG is operating at an effective pressure, that is the pressure actually pushing the BB, of only a few tens of PSI. Doesn't matter much if the compressor is supplying 120 PSI or more, there is just too high a gas flow rate and too much pressure drop in the supply line to actually get anywhere near 120 PSI pushing the BB.

In order to significantly boost the muzzle velocity of a BBMG you probably need to figure out a way to chamber the BBs individually and use a valve to pulse the air flow to the BB.

Posted: Tue Oct 23, 2007 11:53 am

by jackssmirkingrevenge

jimmy101 wrote:The limiting factor really isn't the pressure, it is the air flow rate and the resulting pressure drop.

If you could actually get 120 PSI behind a BB in a BBMG you would get muzzle velocities much higher than 300~350 FPS the typical BBMG gets.

Folks have figured it out before, the typicall BBMG is operating at an effective pressure, that is the pressure actually pushing the BB, of only a few tens of PSI. Doesn't matter much if the compressor is supplying 120 PSI or more, there is just too high a gas flow rate and too much pressure drop in the supply line to actually get anywhere near 120 PSI pushing the BB.

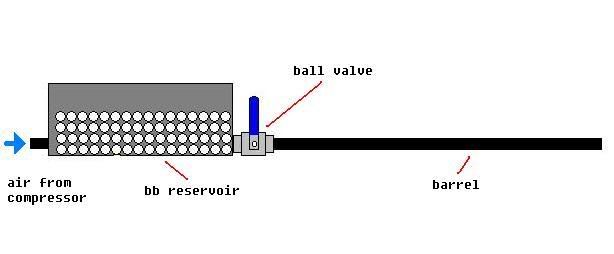

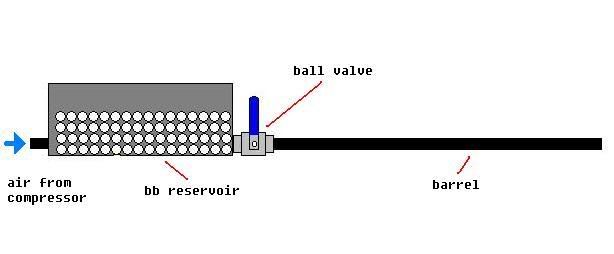

Surely you've seen my

ball valve strafer?

Posted: Tue Oct 23, 2007 3:04 pm

by jimmy101

Jackssmirkingrevenge, yep, saw that one. I made a mini-cloud-BBMG using a diaphram valve. The valve isn't after the chamber but the chamber is so small that there is a little less pressure drop.

From

here.

As it is, this gun gives a ROF of ~7200 RPM (more than a minigun but it only holds ~100 BBs), muzzle velocity 350 FPS. If the ghetto coupler that connects the quick connect to the valve was bigger then the muzzle velocity would probably be increased significantly.

On the linked page (near the bottom) is a calculation of the effective pressure for my vortex BBMG. ... just

18.6 PSIG from a pump resevoir of 120 PSIG. If I could actually get 120 PSIG in the barrel of the gun the muzzle velocity for steel BBs and a 3' barrel is calculated to be in the vicinity of 800 FPS. A photo of my vortex is attached.

Posted: Tue Oct 23, 2007 3:16 pm

by jackssmirkingrevenge

I remember that one from spudtech, that actually inspired me to take a second look at our old washing machine before it was disposed of

On the linked page (near the bottom) is a calculation of the effective pressure for my vortex BBMG. ... just 18.6 PSIG from a pump resevoir of 120 PSIG.

I had hooked up a gauge to the chamber on my

vortex project, the pressure never exceeded 20 psi from a 110 psi input.

While I can't fault your calculations, the ball valve design technically gave me a full 110 psi behind the BB as it started down the barrel since the chamber was already pressurised, but even so with a 25 inch barrel I only got close to 400

fps with steel BBs. This is more than twice the muzzle energy of the vortex block, but still short of your predictions. Of course my barrel is shorter and using a lower pressure, but still.

If I had the facilities, I would go the "American" way and hook up a high pressure chamber to an unregulated SCUBA tank and let her rip, to hell with efficiency, just add more pressure! - but this is a luxury i can ill afford so i'm stuck with ways of making the best of what I have, and this means thinking of individually chambered BBs and pulsed air.

Posted: Tue Oct 23, 2007 3:50 pm

by windshrike

jackssmirkingrevenge wrote:I remember that one from spudtech, that actually inspired me to take a second look at our old washing machine before it was disposed of

On the linked page (near the bottom) is a calculation of the effective pressure for my vortex BBMG. ... just 18.6 PSIG from a pump resevoir of 120 PSIG.

I had hooked up a gauge to the chamber on my

vortex project, the pressure never exceeded 20 psi from a 110 psi input.

While I can't fault your calculations, the ball valve design technically gave me a full 110 psi behind the BB as it started down the barrel since the chamber was already pressurised, but even so with a 25 inch barrel I only got close to 400

psi with steel BBs. This is more than twice the muzzle energy of the vortex block, but still short of your predictions. Of course my barrel is shorter and using a lower pressure, but still.

If I had the facilities, I would go the "American" way and hook up a high pressure chamber to an unregulated SCUBA tank and let her rip, to hell with efficiency, just add more pressure! - but this is a luxury i can ill afford so i'm stuck with ways of making the best of what I have, and this means thinking of individually chambered BBs and pulsed air.

Don't you mean fps?

If I may suggest it, how about an o-ring that fits just around a bb in the ball valve in the chamber; that way, when the valve is being opened, air doesnt leak before the ball valve opens enough to fire.

This may seem crazy, but JSR, try charging that cloud with your shock pump to 350 and see what happens. I'd like to know the velocities you get from that!!!!!

EDIT: I mentioned this in another thread but no one paid any attention

..................................

Anyway, try using a piston or QEV(with a small chamber refilled from a larger one) to feed air to a vortex block. The higher flow should enhance the venturi effect, not to mention making burst fire possible, and possibly semiautomatic with careful adjustment of the size of the chamber.

Posted: Tue Oct 23, 2007 4:00 pm

by ShowNoMercy

Would it be possible to run two pressure lines? One to propel bbs into a vortex block and the one hugging the barrel and venting downwards out the barrel. That way you could actually have a high pressure in your barrel and use whatever pressure you need to achieve cycling.

Posted: Tue Oct 23, 2007 11:34 pm

by jackssmirkingrevenge

windshrike wrote:Don't you mean fps?

yes

duly edited

If I may suggest it, how about an o-ring that fits just around a bb in the ball valve in the chamber; that way, when the valve is being opened, air doesnt leak before the ball valve opens enough to fire.

That's what I did with my prototype

This may seem crazy, but JSR, try charging that cloud with your shock pump to 350 and see what happens. I'd like to know the velocities you get from that!!!!!

EDIT: I mentioned this in another thread but no one paid any attention

..................................

Anyway, try using a piston or QEV(with a small chamber refilled from a larger one) to feed air to a vortex block. The higher flow should enhance the venturi effect, not to mention making burst fire possible, and possibly semiautomatic with careful adjustment of the size of the chamber.

Have a look

here

. Your either going to need four different compressors or one helluva big one. It would be worth it though.

. Your either going to need four different compressors or one helluva big one. It would be worth it though.