Page 2 of 2

Posted: Mon Oct 29, 2007 3:45 am

by mtronic

I used the fine steel wool in the first layer and then real sheep wool in the second. I wraped the wool in a spiral around the inner sleeve rather tightly and that gave a really tight fit. I found this to be better than just packing it in loosly. If I were making another pneumatic suppressor I would use a soft packing for both layers and add baffles, as JSR pointed out that steel wool works best in combustions.

Good luck on the build and take some pics too

Posted: Tue Oct 30, 2007 10:05 am

by Lentamentalisk

Which would work better?

keep in mind I am using the full barrel shrouding method.

Posted: Tue Oct 30, 2007 10:35 am

by jackssmirkingrevenge

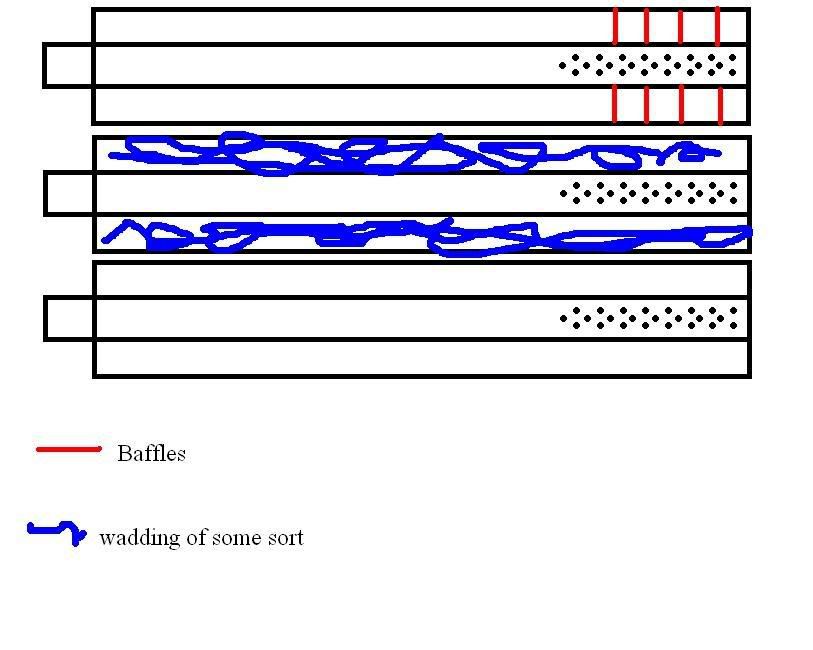

Depending on your getting the wadding consistency right, this:

Posted: Tue Oct 30, 2007 12:15 pm

by ALIHISGREAT

i will try that on my 6mm sniper because it will have a phat silencer

Posted: Tue Oct 30, 2007 1:11 pm

by williamfeldmann

So, the batting material only really needs to be in the largest, first baffle? Is that for conveinence or is there an actual reason behind that?

It appears in his drawing he would have a lot of small holes, will that work better than fewer bigger holes? Since he is using paintballs eventually, I am assuming he will have pretty nice spherical ammo, so the holes shouldn't cause too much of a problem on that end.

Posted: Tue Oct 30, 2007 1:18 pm

by ALIHISGREAT

well i think its because it allows you to have a massive first chamber without drilling holes all the way up the barrel and putting baffles in because the wadding has the same effect as baffles, i think.

Posted: Tue Oct 30, 2007 1:29 pm

by jackssmirkingrevenge

williamfeldmann wrote:So, the batting material only really needs to be in the largest, first baffle? Is that for conveinence or is there an actual reason behind that?

You could put the wadding in the forward baffles too, it's a matter of trial and error - wadding is an inexact science, depending on what materials you use and how densely you pack it, sometimes no wadding at all will give better results.

This for example is a Logun silencer popular with airgunners in the UK:

The black wadding wraps around the perforated tube and is similar in consistency to

this stuff used for washing dishes. Some users insist that it works better without it, the thing with silencers though is that it's extremely subjective, without a decibel meter it's sometimes hard to tell what actually makes a difference.

t appears in his drawing he would have a lot of small holes, will that work better than fewer bigger holes?

The important thing is the total area of the holes - the bigger the area, the more flow to the silencer body and the less friction with the projectile. That said, for a given area, more smaller holes could potentially create more turbulence and therefore increase the effectiveness of the silencer.

Posted: Tue Oct 30, 2007 2:28 pm

by ALIHISGREAT

unfortunatly i don't happen to have a decibel meter lying around so i have no way of testing

i might try a silencer design like that for my 6mm and i will use j-cloth to wrap around the spacers, my mum has tons

Posted: Tue Oct 30, 2007 5:10 pm

by mtronic

just make sure if your using it for a paint ball rifle that you clean the inside of the barrel after you drill it. It will have heaps of burs, I just made a dowel/sandpaper "dremel" for mine. You dont want those pbs rupturing before they get a chance to splat on something cool

Posted: Tue Oct 30, 2007 5:28 pm

by ALIHISGREAT

yeah i did it the same way. but it was hard because the drill bit got hot so the was a lip on the inside of all the holes cos the plastic was melting.

Posted: Tue Oct 30, 2007 6:34 pm

by mtronic

hmm paitence

u could use a round file, that may help aswell?

Posted: Tue Oct 30, 2007 7:12 pm

by Lentamentalisk

On the logan silencer, does the J Cloth just wrap around once, or how many times? Also, what are the springs and washers for?

Posted: Tue Oct 30, 2007 11:51 pm

by jackssmirkingrevenge

The j-cloth goes around the perforated tube and overlaps a little but not enough for a double layer,

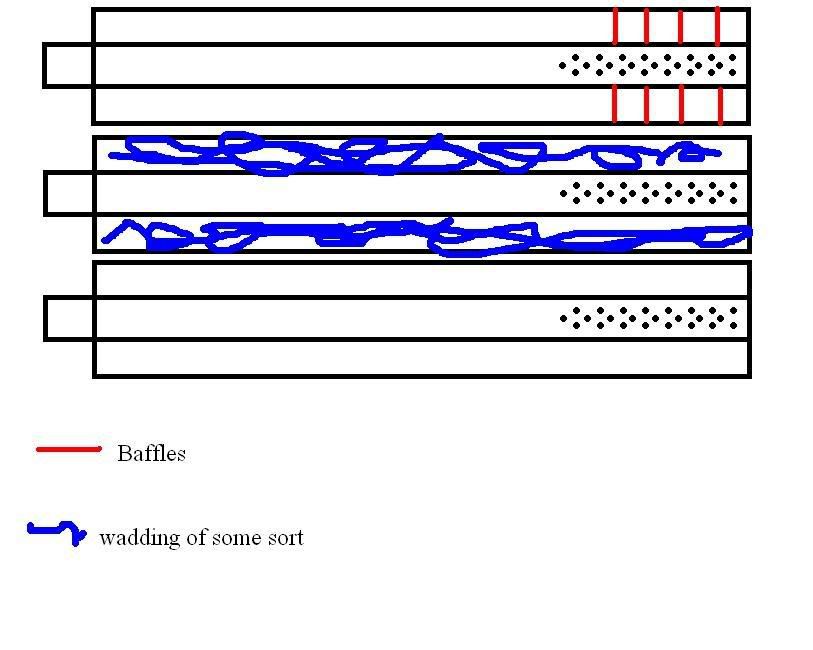

The washers and springs go inside the perforated tube, the washers acting as baffles and the springs as spacers, similar in construction to this:

Posted: Wed Oct 31, 2007 9:04 am

by Lentamentalisk

That is very smart, I'll have to do that

Posted: Wed Oct 31, 2007 12:14 pm

by ALIHISGREAT

jackssmirkingrevenge wrote:The j-cloth goes around the perforated tube and overlaps a little but not enough for a double layer,

The washers and springs go inside the perforated tube, the washers acting as baffles and the springs as spacers, similar in construction to this:

so the perforated tube would be ontop of the barrel with baffles inside, then the cloth on top of the tube then the silencer body? this could work quite well on my 6mm cos its gonna have a 15mm copper shroud over the 8mm barrel.