Page 2 of 3

Posted: Thu Jun 26, 2008 4:52 pm

by iknowmy3tables

whoops deleted, my computer was acting up didn't think it posted before it froze and shutdown

Posted: Thu Jun 26, 2008 4:54 pm

by iknowmy3tables

deleted

Posted: Thu Jun 26, 2008 5:57 pm

by iknowmy3tables

your lucky you got that to work, must have been the rotational momentum,

me and jack tried something similar

http://www.spudfiles.com/forums/making- ... 12899.html

its for a completely different purpose but it annoyed the crap out of us to get the thing to cycle

however there's almost no point in making a motor when you can buy an air motor, they're closely machine turbines used in impact wrenches, and a handful of pneumatic appliances, I'd still try installing an air motor eventually because it will probably be more efficient and reliable

Posted: Thu Jun 26, 2008 6:50 pm

by STHORNE

looks very innovative. nice work, can't wait to see the finished product!

Posted: Fri Jun 27, 2008 1:16 am

by trollhameran

iknowmy3tables: It is the momentum from the drill that makes it work in this case because without that it hangs open for along time like Jack said it it did in the thread you posted. I will look into air motors that i can buy to see if i can find one that would suit this purpose but if i cant ill work on making a better version of mine.

Thanks STHORNE much appreciated

Posted: Mon Jun 30, 2008 5:50 am

by trollhameran

i have now started work on the new frame, and a new way of opening and closing the valve rapidly, it will be based on an old fashioned water pump but instead of the handle being pumped by hand it will be pumped by a wheel with teeth on it connected to the shaft that the barrels rotate on, each tooth will pump the arm for a separate barrel. If that doesnt make sence i will be posting pics of what i have done so far and a diagram later on today

Posted: Mon Jun 30, 2008 1:50 pm

by iknowmy3tables

it does really make any sense, are you talking about a the classic Gatling gun hammer cocking mechanism only it's used to cock an air piston like those in airsoft guns

http://science.howstuffworks.com/machine-gun4.htm (see animation for Gatling gun)

Posted: Mon Jun 30, 2008 3:02 pm

by trollhameran

No the force form the air being input will push the piston down allowing air to escape and then the teeth on the wheel will push the piston back up as they rotate, then when the piston reaches the top again the piston arm slides off the tooth allowing the piston to drop down again.

Posted: Tue Jul 01, 2008 8:05 am

by iknowmy3tables

why do you have the piston powered by air , why not inject the input air into the barrel, your really going to need a diagram to explain this

Posted: Tue Jul 01, 2008 3:46 pm

by trollhameran

the piston is powered by air because then the piston is used to rotate the barrels and the air outlet is used for firing the projectile.

I am probably scrapping this design for now though as I have thought of an extremely simple yet quite tedious way of doing it. I will post diagrams of my new design once they are drawn which should be about 20 minutes

Posted: Tue Jul 01, 2008 4:06 pm

by SEAKING9006

I like how for about a few weeks, it's been nothing but theories and ideas, and now, all of the sudden, everyones drawing up diagrams and planning prototypes.

Posted: Tue Jul 01, 2008 4:10 pm

by trollhameran

lol yeah I think it might be because a fair amount of the people on this site are at school or college and were all breaking up for summer now so we have alot of time on our hands. Also alot fo the theories on here require large amounts of money to be built which is a big problem for alot of us. I have every intention of building everyone of my theories when time and money allows me to. I have a large pad of paper filled with drawings and ideas most of which havnt been posted on here yet.

Posted: Tue Jul 01, 2008 4:18 pm

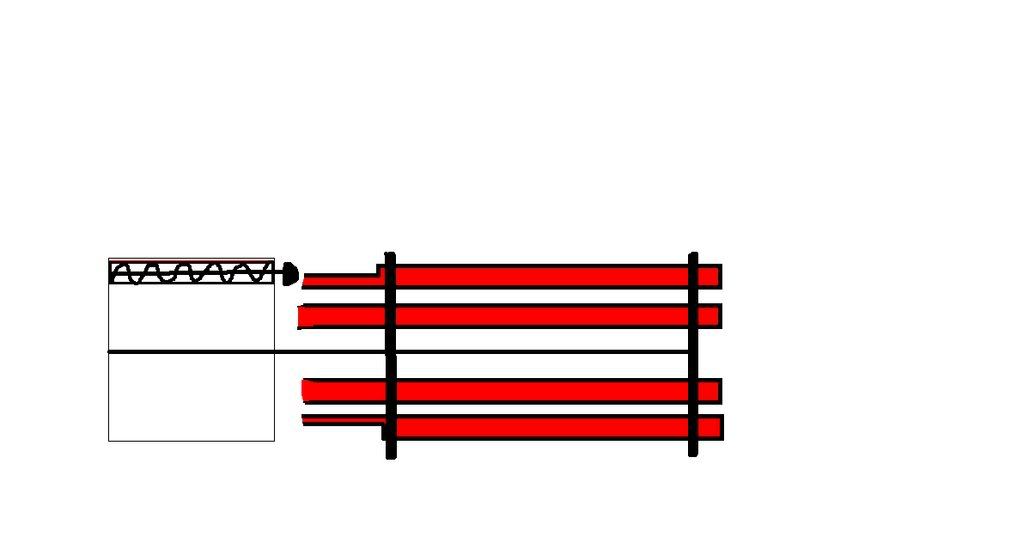

by trollhameran

Posted: Tue Jul 01, 2008 4:25 pm

by SEAKING9006

I don't think a schrader will be either fast or reliable enough, because of the way you have to fill a schrader. Maybe instead, you could and push a sharp pointed spike inside the sheel forward with a small diameter air piston inside the breech face, and pop the forward burst-disk.

Posted: Tue Jul 01, 2008 4:35 pm

by trollhameran

The shrader is only there for filling the shells, otherwise i would get rid of it, the ram will only hit the shrader because it is at the back of the shell where the piston is and pushing the shrader forward will move the piston and small diameter pipe forward to burst the disc