Page 2 of 3

Posted: Sat Aug 16, 2008 4:22 pm

by PVC Arsenal 17

That was straight from my compressor. I think the gauge was reading 90 psi.

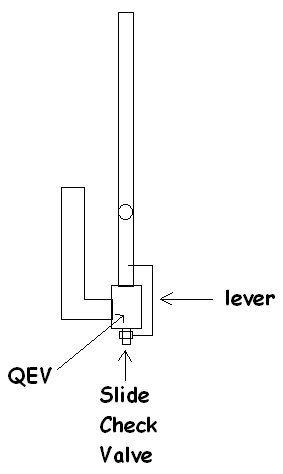

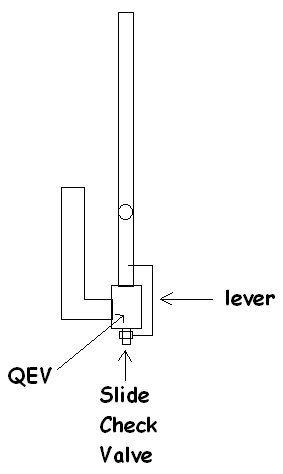

This was just a test. I will be configuring it so that a golfball can be dropped down the barrel (like a mortar) and it will strike a lever that moves the slide check and fires the gun.

It slides rather easily too and with leverage the ball should have no problem closing the check.

Posted: Sat Aug 16, 2008 4:42 pm

by daberno123

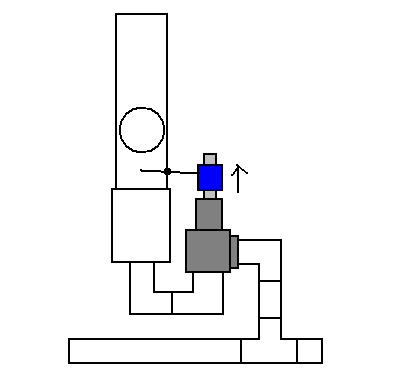

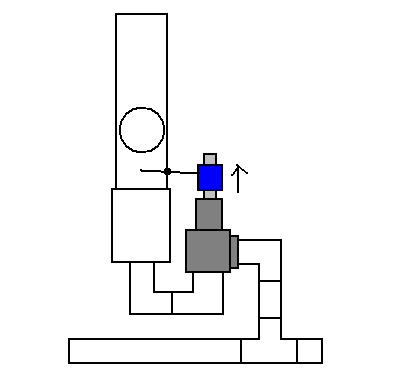

What sort of lever did you have in mind?

Something like this? Or more complex?

Posted: Sat Aug 16, 2008 4:52 pm

by PVC Arsenal 17

Originally I was going to go with an overcomplicated design but I reworked it into one similar to what you have with a pushrod. The only difference really will be the chamber. It will form a base that can hopefully allow me to adjust the angle.

Posted: Sat Aug 16, 2008 4:57 pm

by daberno123

Simpler is always better.

I look forward to seeing it completed.

Posted: Sat Aug 16, 2008 5:03 pm

by PVC Arsenal 17

This is what I had in mind originally, way too complicated. I will use your idea.

Posted: Sat Aug 16, 2008 5:15 pm

by daberno123

Thanks for using my idea, I think I'm going to do something similar, involving an 1.5" QEV...

Posted: Sat Aug 16, 2008 5:30 pm

by PVC Arsenal 17

daberno123 wrote:Thanks for using my idea, I think I'm going to do something similar, involving an 1.5" QEV...

And thank you!

For a 1.5" QEV though, I don't think drilling more holes in the slide check will be enough. You might need to pilot the main QEV off a smaller one first.

Posted: Sat Aug 16, 2008 5:35 pm

by daberno123

The QEV already has a second valve built into it for piloting, and the second valve has 1/8" threads in the pilot port. I've measured the pilot volume of the second valve and its under 10cc, so hopefully I won't have to do any modifications to the slide check valve.

But I'll be prepared. I've just recently acquired five 1/4" QEVs so one of them could be added to help pilot.

Posted: Sat Aug 16, 2008 6:45 pm

by PVC Arsenal 17

Built in? That's awesome. Where did you find that?

Posted: Sun Aug 17, 2008 2:32 am

by trollhameran

@ Gippeto: I think about 4 holes of between 2 and 4 mm diameter should be ok, because a blowgun only has about an 8mm hole, and they usually work as pilots, so having 4 4mm holes should allow a faster opening than a blowgun, and also a larger diameter vent.

I think im going to see if I can find what I need to make one today, and have a go.

PVC Arsenal 17: If I manage to build a working slide myself, would you mind if I posted it in this thread, as if it works well it may be of interest to you.

Edit: I have made a working slide valve

http://www.spudfiles.com/forums/home-ma ... ter,0.html

Posted: Sun Aug 17, 2008 9:43 am

by daberno123

There were a bunch of them on eBay a while back for like $8. Right now its on an unposted gun that will soon be taken apart.

Posted: Sun Aug 17, 2008 10:51 am

by PVC Arsenal 17

I don't mind at all, troll.

And my valve was one of the $8 ones from ebay. Check my link on page one.

Posted: Sun Aug 17, 2008 12:40 pm

by ALIHISGREAT

what size is your slide-check? i ask because i'm not sure what size to get for my coaxial (28mm chamber - 15mm barrel)

Posted: Sun Aug 17, 2008 12:58 pm

by PVC Arsenal 17

The inlet is 1/8" NPT female. Outlet is 1/8" NPT male.

It's about 2" long and just over 3/4" diameter at its thickest point.

Posted: Sun Aug 17, 2008 1:58 pm

by ALIHISGREAT

ok thanks i'll get a 1/8" or 1/4" one then.