Page 2 of 3

Posted: Thu Nov 20, 2008 1:43 pm

by jitup

Thanks for the info, I am not familiar with costs because I never had any thing done before. In my area the only material readily avialible at a reasonable price is hard wood for vortex blocks, I should have chosen the red oak instead of poplar. (would bondo work Never tried it) I just thought if he had acsses to a cnc it would be a lot quicker to have some one put the info in and let the machine do the work at a fair price. I have access to most of the tools I need accept a milling mahine and a lathe. I am considering building a mini lathe. I have a motor that would work well but I am not sure of what else I need. I am still doing reaserch on the best way to put one together. if any one has any experience with this idea PM me, and if I am getting in over my head let me know so I do not waste any more time.

Posted: Sat Nov 22, 2008 12:17 pm

by SEAKING9006

I don't know if this conversation is related to the topic, but you really don't need to computer machine vortex blocks. I made my first one out of a 1x2 using not but a hacksaw and a drill. Granted, I messed up drilling out the slot for the barrel, but it functioned. Not well, but it worked. All I needed to do was steady my aim a bit better and watch my measurements. And yes, I recommend using bondo. I've seen it used very well, and bondo doesn't require separate discs to fit into pipe, I had to make three plywood discs with a dremel to use my block.

Posted: Sat Nov 22, 2008 12:26 pm

by F.E.A.R._Sniper

yeah, but i can get vortex blocks made out of metal (1 point for me due to the reliability) I can get them down to extremely tight tolerances (1 point due to me for accuracy) I can make them in variable sizes and calibers (1 point due to me for variety and versatility)

Thats 3 points to me over nothing to building one out of bondo or wood or anything else. The only way that building one yourself instead of getting one from me benefits you at all is that you get to save some money

Posted: Sat Nov 22, 2008 12:33 pm

by SEAKING9006

There really aren't any advantages from making blocks from metal over bondo, save for not having to make it yourself. But isn't that supposed to be half the fun? Now, if they were YOUR tools, then that would be cool, but I don't know if Larda appreciates competition.....

Posted: Sat Nov 22, 2008 12:44 pm

by F.E.A.R._Sniper

eh, i haven't made any hybrids YET so he is fairly safe for now

Posted: Sat Nov 22, 2008 3:57 pm

by jitup

since we are talking about vortex blocks, would the same principle be able to be used with marbles or would there not be enough air flow to push them with adequate force for any real fun? I made my own vortex blocks aswell, but I am considering building inline bb guns and selling them to some people I know and at the flee market during the summer and it would be better to have several made if he will sell them at a decent price. I make all the compoments for my own guns, except for a valve I am working on designing, but that is because I do not have access to a lathe or milling machine.

So, say I wanted a 2x2 vortex block for the sake of argument, with a 1/4 hole for the barrel how much would it cost? 8)

Posted: Sat Nov 22, 2008 4:51 pm

by SEAKING9006

IIRC, there WAS a marble BBMG made. It did, however, use up air like nothing and didn't fire very many marbles at a very high velocity. A bolt action is more suitable.

Posted: Sat Nov 22, 2008 5:52 pm

by frankrede

SEAKING9006 wrote:IIRC, there WAS a marble BBMG made. It did, however, use up air like nothing and didn't fire very many marbles at a very high velocity. A bolt action is more suitable.

Brian the Brain made it I believe.

Posted: Sun Nov 23, 2008 4:39 pm

by jitup

thanks about the marble vortex, but I already abondoned that plan.

How about those vortex block quotes

Posted: Mon Nov 24, 2008 5:50 pm

by Imortal87

If you wanted a 2x2 block 1 inch thick with a 1.0 or .75 inch bb intake hole and .250 air/barrel holes all drilled and reamed I would say about 10 to fifteen bucks per piece minimum. if you wanted any thing tapped or off-set in odd directions it might cost more. And this all depends on the material you chose and if you supply material it will cost less.

Posted: Mon Nov 24, 2008 6:07 pm

by SEAKING9006

What? I had no idea they'd be that cheap. Emachineshop would charge at least $150.

Posted: Mon Nov 24, 2008 6:56 pm

by jitup

I was expecting between $10 and $15 for nothing special. would it be better to have some one make them (aluminum) or would it be pretty simple to make them out of bondo?

Back to the Cad drawings, I think it is really cool that he is offering to make models of peoples guns, I am under the assumption he will model them for free (correct me if I am wrong) which makes it even beter.

FEAR let us know the info we need to supply you with for you to be able to make the models, and I am sure people will take you up on your offer.

Posted: Mon Nov 24, 2008 7:37 pm

by F.E.A.R._Sniper

yeah I'm just waiting on the cd to get here from that company and i will be able to start modeling right away. yes it will be free, you just need to give me a fairly clear description of what you want.

Does anyone know what the optimum ratio equation is for a vortex block?

Posted: Mon Nov 24, 2008 8:33 pm

by jitup

i belive it is like 1.95 in x1.95 in 3 in long w/ 3/4 "hole" 1/4 inch from front

the hole should hang over the edge 1/8 in, and if it is a 1/4 in brake line, it sould be placed 1/32 below of the exact center

Posted: Mon Nov 24, 2008 9:14 pm

by F.E.A.R._Sniper

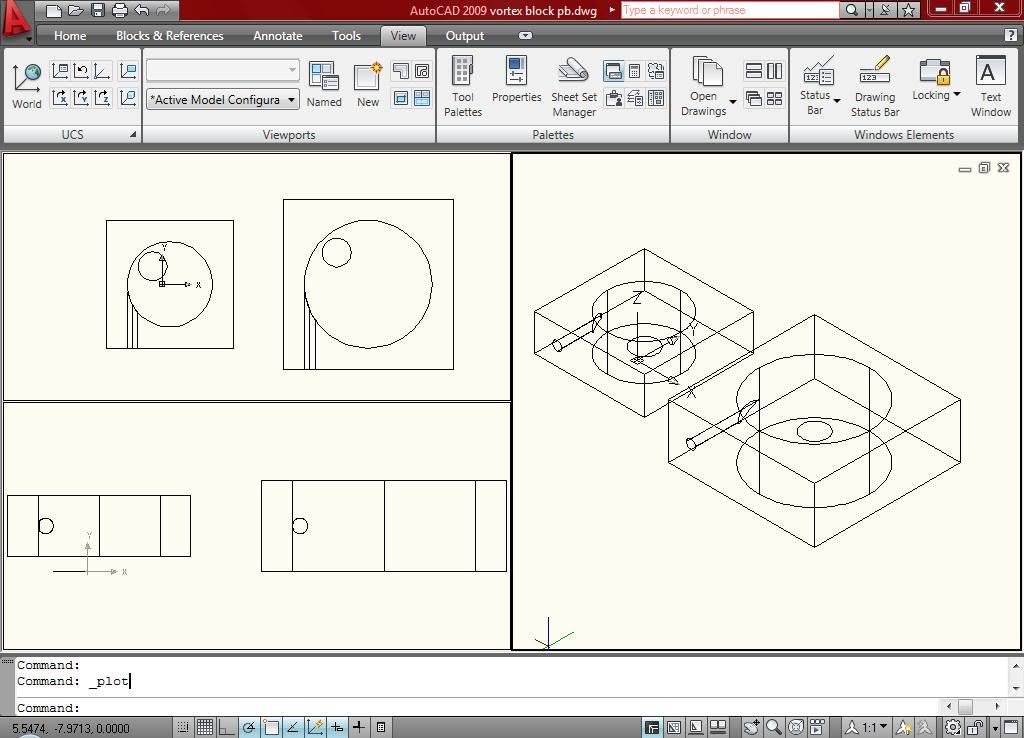

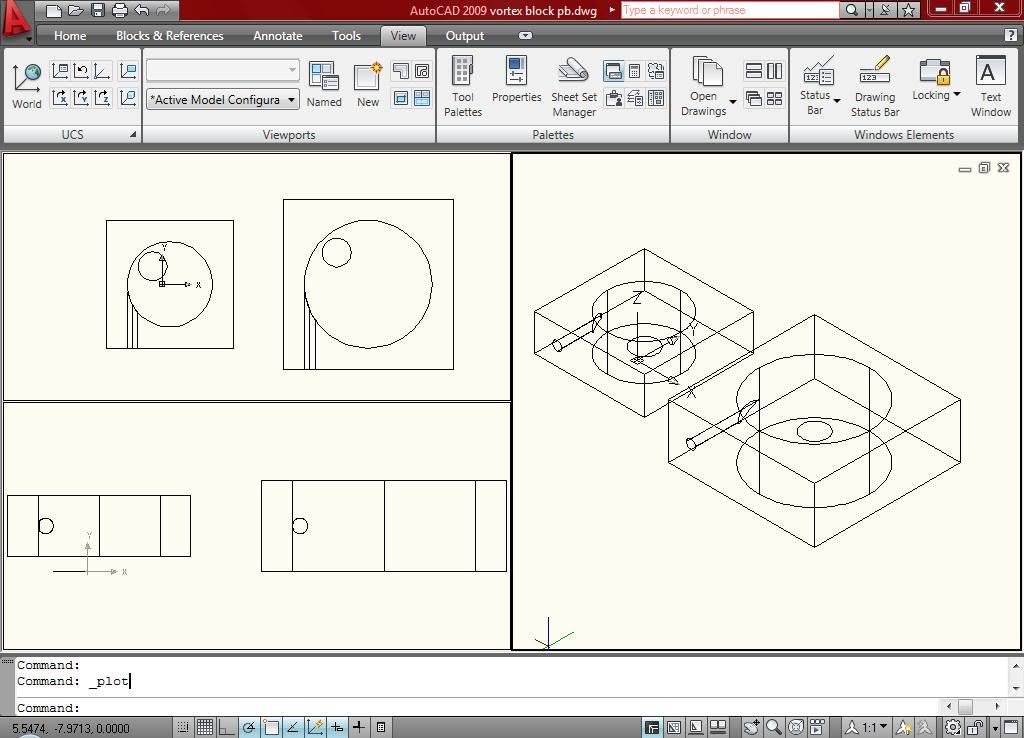

here is the start of my paintball vortex block.

the small one is a 3 in. x 3 in. x 1 in. with a 2 inch cvortex circle fed by a 1/4 inch hole (no barrel yet)

the large one is a 4 in. x 4 in. x 1.5 in. with a 3 inch vortex circle fed by 1/4 inch hole (no barrel yet)

the small circle is .68 caliber just like a paintball

which one do you guys think will be best to use?