Page 2 of 2

Posted: Mon Jan 25, 2010 6:28 pm

by MrCrowley

I would suggest you go here:

http://www.spudfiles.com/forums/search.html

Or straight to the Pneumatic Cannon Showcase section and look through cannons which have similar design features to yours, such as a 3/4" piston housing in a tee. Then you can see how other people did it

Posted: Mon Jan 25, 2010 6:52 pm

by Gun Freak

ok thanks.

and if i screw it in the side... would teflon tape hold it?

Posted: Mon Jan 25, 2010 8:29 pm

by pvcmaster

If by hold it you mean hold pressure, then yes teflon tape works great for that. Just make sure you drill a hole small enough that the threads dig into the pvc and leave grooves, it should take some effort to thread in the first time. I would suggest a threaded schrader valve like this one:

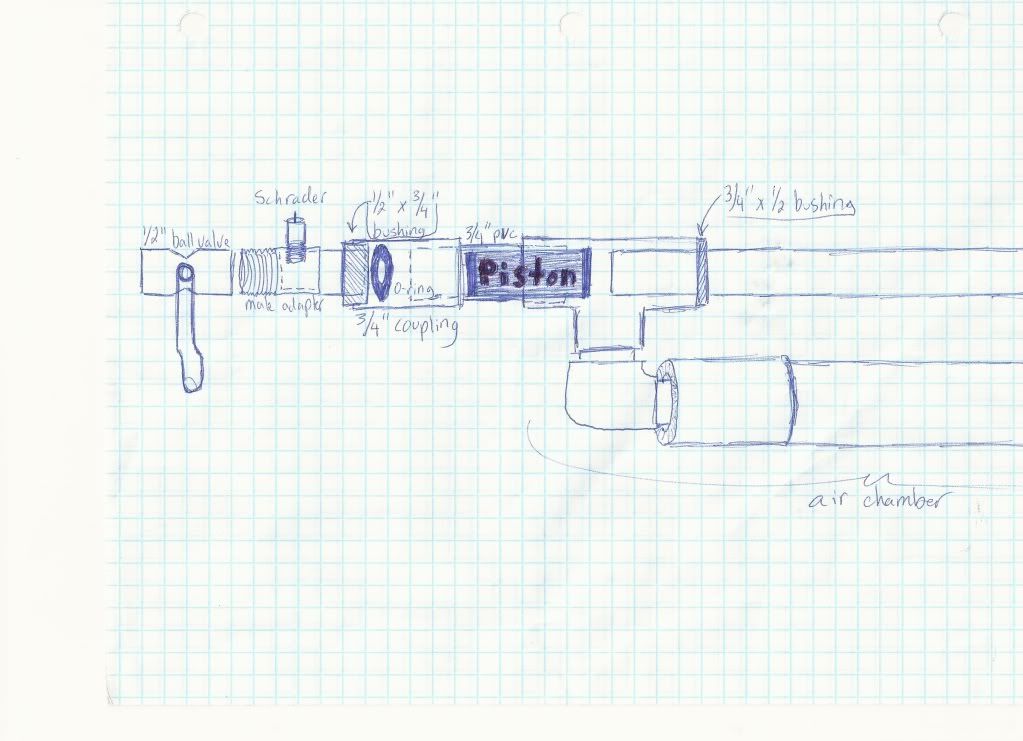

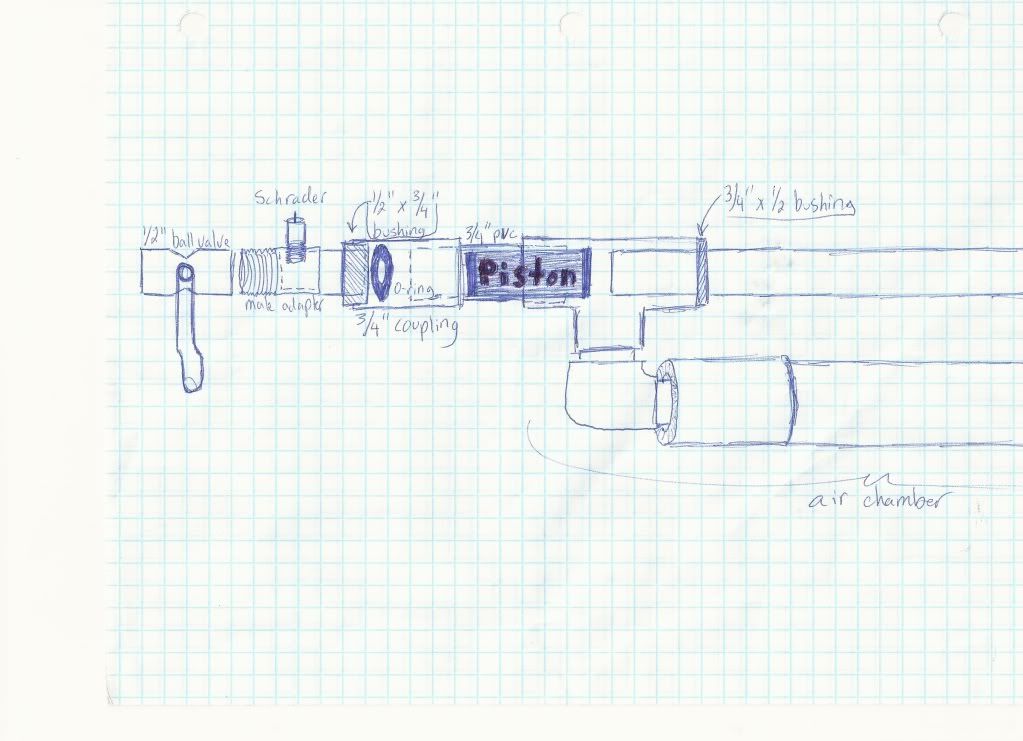

Why is there an o-ring between the washer and the 3/4" pipe on the left of the piston?

Posted: Mon Jan 25, 2010 9:43 pm

by Gun Freak

to seal the back so all pressure is going out the barrel. is that not needed?

ps. i already have the threaded schrader. thnx for comfirmation

Posted: Mon Jan 25, 2010 10:48 pm

by pvcmaster

Well based on your drawing i assumed that you are using one of the conical reducers, not a reducing bushing, and that it would slip over the section of 3/4" pipe that would extend slightly out of the tee. In that case an o-ring would not be necessary, but if it is a bushing that is pushed into the tee then yes its very important.

Posted: Tue Jan 26, 2010 6:49 am

by Gun Freak

thanks i understand. so i'll use a 3/4 x1/2 bushing with o ring... is the washer needed or not

Posted: Tue Jan 26, 2010 11:14 am

by Gun Freak

Hey guys,

I redesigned it this morning without the stock or anything so its a close up. I'll post it later, because I'm at school now lol. Spudfiles isn't blocked!

Posted: Tue Jan 26, 2010 4:31 pm

by Gun Freak

ok so heres the new scan of my final drawing-

Posted: Tue Feb 02, 2010 10:45 am

by Gun Freak

i have the same problem... im thinking a little rubber gasket would do the trick

Posted: Tue Feb 02, 2010 11:11 am

by om3n

How exactly are you making the sealing surface that the piston pushes against to seal the barrel off? I'm in the middle of designing a gun of my own, and this is where I'm stuck

Posted: Wed Feb 03, 2010 4:22 am

by Rokmonkey

Neoprene gasket should work, then again I also am working on a piston valve. Points to Gun Freak for actually getting up and doing it, Im still "thinking" about it.

Posted: Wed Feb 03, 2010 4:43 pm

by Gun Freak

Mine's almost done. All I got to do is get the neoprene washer and put it on my piston, which I made (it's hot glue around a wine cork) then I have to glue the rest together. Most parts are already glued.