Page 2 of 2

Posted: Wed Sep 22, 2010 7:47 pm

by ramses

personally, make the slots with something else, then finish with a file. Or get an end mill and use that in the drill press. You need to cut on the side, and drill bits aren't meant for that.

a solid carbide one would flex the least.

If not, DEEP center drills, pilot drill, then drill to size. If possible, retain some meat so that it's not a finished slit and remove that later. It should help with the bending of the drill.

clamp it tight, and minimize quill extension.

Posted: Wed Sep 22, 2010 8:14 pm

by dewey-1

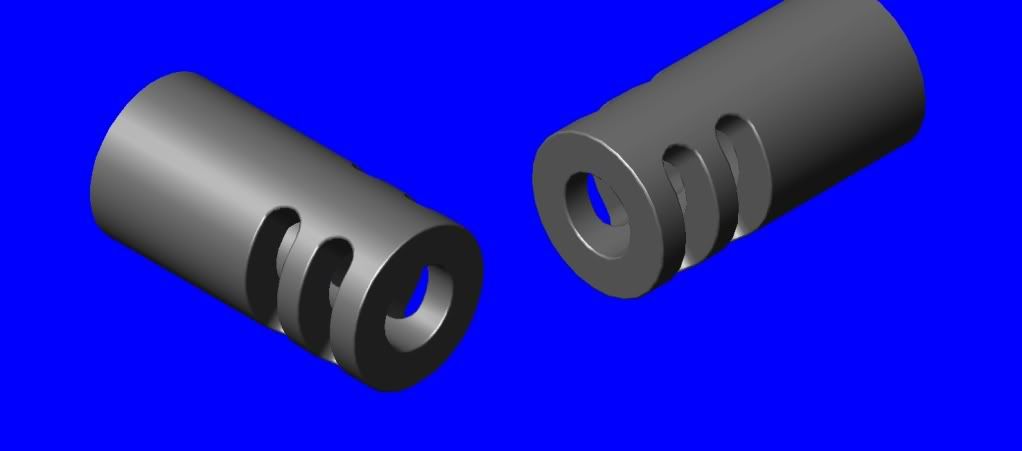

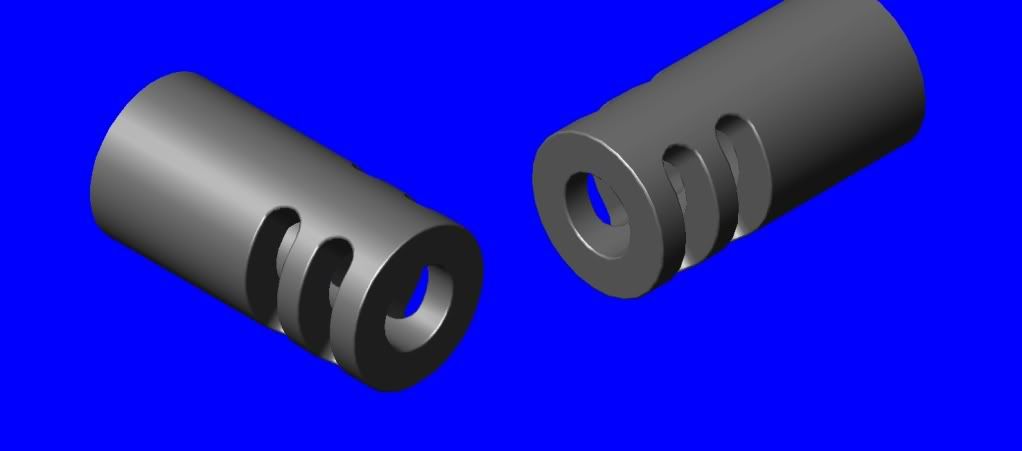

Here is a preliminary 3D CAD file!

Posted: Wed Sep 22, 2010 8:33 pm

by twizi

yeah dewey thats exactly what im looking for

Posted: Thu Sep 23, 2010 5:11 pm

by dewey-1

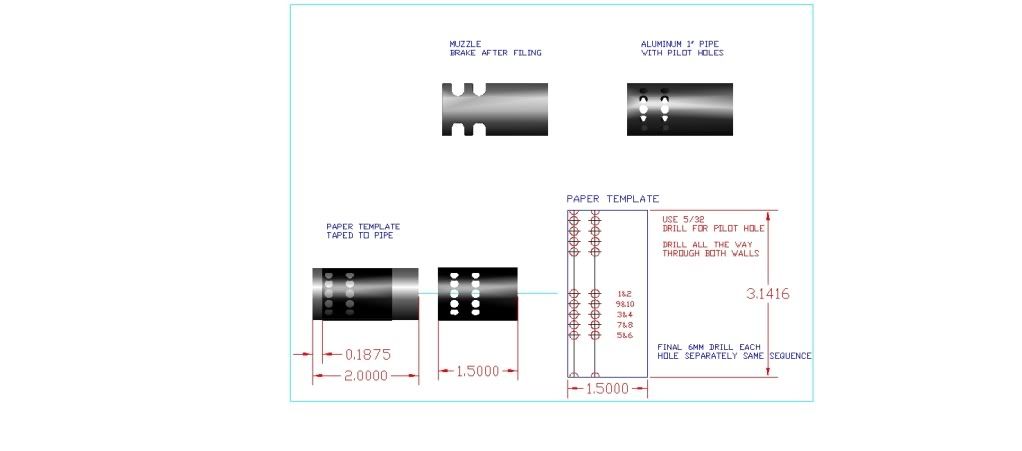

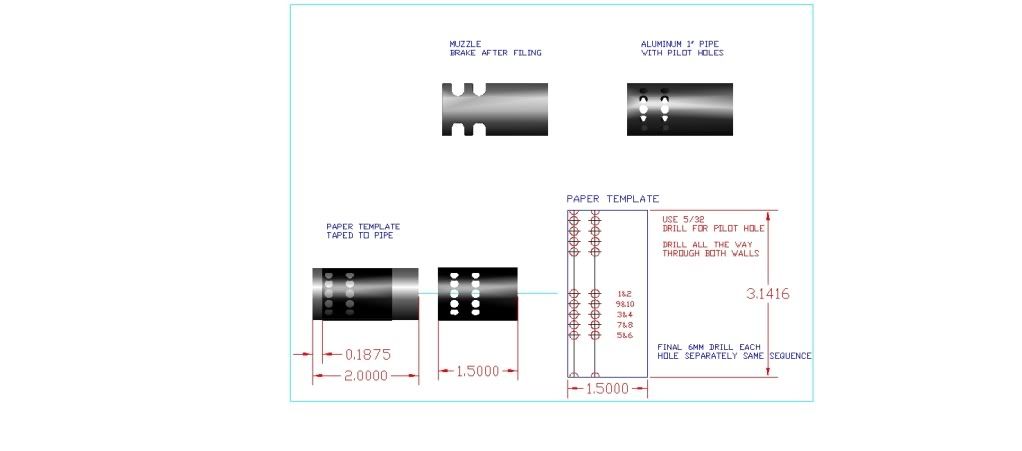

I have the drawings done.

Just have to convert to some useable format for you to print out accurately.

Do you have Sketchup or e-drawings viewer?

If you do, it will be more accurate than bmp, jpeg or png file conversions.

Posted: Fri Sep 24, 2010 4:57 pm

by twizi

thank you im drilling right now

Posted: Tue Nov 09, 2010 10:14 pm

by Selador

Why are you drilling those ?

Just use a hacksaw and then a round file.

Posted: Thu Nov 11, 2010 7:44 pm

by motorfixer1

A single ended HSS 4 flute endmill works great for this job even if you don't have a mill. Might be on the pricey side but you don't need a high quality one, just one with a same size shank. High speeds and light feeds. Aluminum should be a piece of cake to do this to even for a novice.

Posted: Thu Nov 11, 2010 9:20 pm

by twizi

Oxbreath wrote:Why are you drilling those ?

Just use a hacksaw and then a round file.

I finshed drilling 2 month and 4 hours ago so it dosent matter i than powder coated the aluminum and it looks great also alot of people dont apreciate when you post in a dead topic

Posted: Fri Nov 12, 2010 1:16 am

by Selador

twizi wrote:

I finshed drilling 2 month and 4 hours ago so it dosent matter i than powder coated the aluminum and it looks great also alot of people dont apreciate when you post in a dead topic

-You- finished drilling 2 months and 4 hours ago.

Someone else might find this thread in a search, and appreciate an easier way to get those slots cut in the barrel.

No one minds if a 'dead topic' is posted to... If something constructive is posted.

Posted: Fri Nov 12, 2010 1:28 pm

by dewey-1

twizi wrote:

I finshed drilling 2 month and 4 hours ago so it dosent matter i than powder coated the aluminum and it looks great also alot of people dont apreciate when you post in a dead topic

So why not show some pictures of the end result?

Ask for help and you get it, but no results from you to show others that it is possible.

I was about to revive your 'dead topic" anyway to get an answer.