Page 2 of 3

Re: Nerf/paintball gun design

Posted: Wed Jun 20, 2007 8:11 pm

by jrrdw

pvcmaster wrote:Sorry, I should have clarified that. The yellow hose is connected to the sprinkler valve only, and is in no way connected to the bike pump setup(goes behind the gun).

Now i am confused.

The sprinkler is the main valve, the pressure equilzes as you fill the main chamber. If you don't have a valve at the other end of the hose, all the air will escape through the barrel because the sprinkler wont be able to pressurize.

Posted: Wed Jun 20, 2007 8:23 pm

by pvcmaster

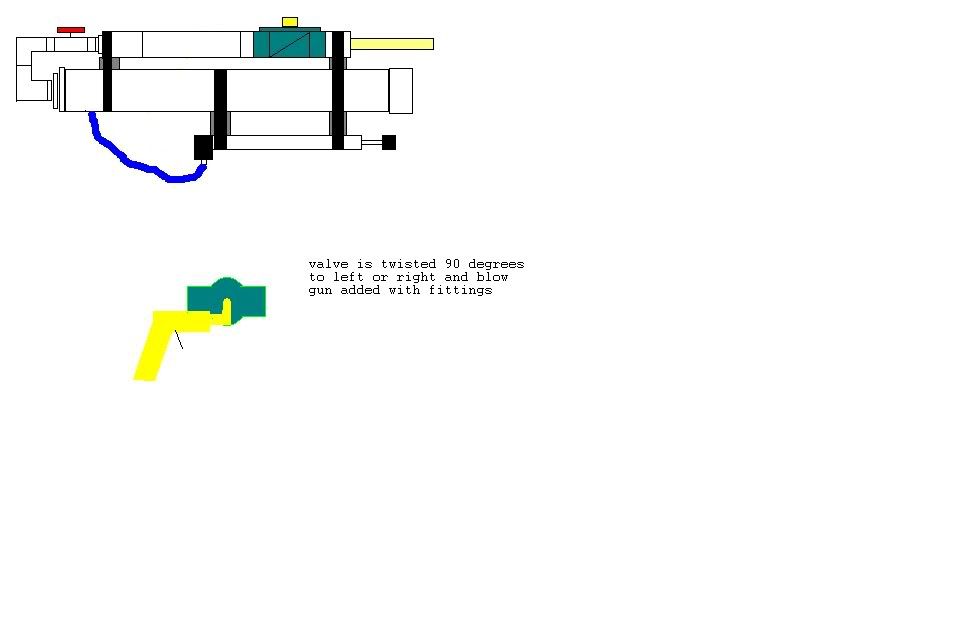

The lower ball valve seals the bike pump off, the upper ball valve equilizes the pressure from the large chamber into the secondary chamber, the sprinkler valve releases the air from the secondary chamber, and the trigger is a blowgun valve to pilot the sprinkler valve.

Sorry if i didnt explain my gun very well.

Posted: Wed Jun 20, 2007 8:46 pm

by jrrdw

pvcmaster wrote:The lower ball valve seals the bike pump off, the upper ball valve equilizes the pressure from the large chamber into the secondary chamber, the sprinkler valve releases the air from the secondary chamber, and the trigger is a blowgun valve to pilot the sprinkler valve.

Sorry if i didnt explain my gun very well.

Now we are back to my oridgenal question. What stops the air from leaking out of the bike pump? There is no valve inbetween the pump and blowgun. The pilot chamber has the same air pressure as the pressure in the main chamber. You said the bike pump leaks at high pressure, having the air line hooked to the blow gun will allow the pressure from any part of the gun inbetween the lower ball valve and the sprinkler valve to leak out of the bike pump. It will just take a little longer because of going through smaller passage ways.

You bypassed the lower ball valve by hooking the pilot air line up to the blow gun. See what i'm saying?

Posted: Wed Jun 20, 2007 9:29 pm

by goathunter

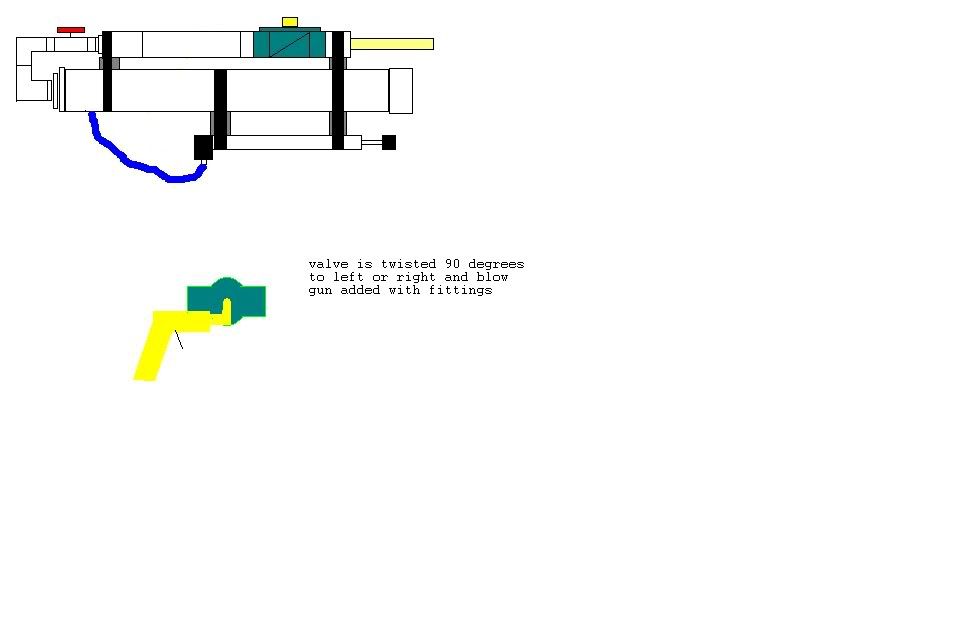

PVCMaster,Here is how I'd rearrange the gun.This design will answer some of the questions of jrrdw's.As well as address the probable flow issues with the current design.

I also noticed the lack of a stock.That could do a workout on your wrists after a while,using it like a pistol.This new design is held like a bullpup.Tell me what you think of the redesign.

Posted: Thu Jun 21, 2007 5:42 am

by jrrdw

Goat, it's still going to leak out of the bike pump. I'd say put the lower ball valve inbetween the blow gun and bike pump, that would solve all the leaking issues.

Posted: Thu Jun 21, 2007 7:41 am

by pvcmaster

I still dont see where it would leak. I positioned the blowgun valve on the handle so that i could use it as a trigger. It is in no way connected to the bike pump, only to the sprinkler valve as a pilot. The lower ball valve can stop air from backflowing and leaking out of the bike pump.

Posted: Thu Jun 21, 2007 4:49 pm

by goathunter

Jrrdw, in the original plan PVCMaster had a schrader valve to connect to the bike pump.I assumed he'd pull it off after filling.Why would it leak?

Posted: Thu Jun 21, 2007 5:34 pm

by pvcmaster

Well, the hose screws on to the valve, and to detach it after each filling would be very slow. I thought that a simple ball valve would be more convienent.

Posted: Thu Jun 21, 2007 5:38 pm

by goathunter

Well in that case, buy a small check valve and use that to connect to the pump.It might actually be cheaper than a ball valve

Posted: Thu Jun 21, 2007 6:14 pm

by jrrdw

In your diagram it looks like the bike pump hose is connected to the blow gun. I was unclear about that, now that i know thats not the case i can now see that it wouldn't leak out of the bike pump. Some builders here have connected the fill through the blow gun, i assumed thats how you did it, looking at your diagram. Can you see how i thought it would leak?

Another question: I see the small springs on each side of the cartridge, how are they kicking out the old shell?

All bolts that i've seen on semi-auto's have a little hook on a pin type piece that hooks the empty shell and pulls it out of the chamber.

Posted: Thu Jun 21, 2007 7:47 pm

by pvcmaster

Yes, i see why you would think that. I guess its my fault. About your second question, are you sure that it was directed to me? My gun does not have springs and is not a semi-auto.

Any way, i have decided to make the second chamber 1-1/2" to increase the distance of the projectile, and the the chamber is now going to be 2" pipe instead of 3" because 3" is much too big proportionally to the rest of the gun. 2" will make it look more like my diagram.

Posted: Thu Jun 21, 2007 8:01 pm

by jrrdw

Opppps, i did post that 2nd qeustion in the wrong place, i'm loosing my mind.

Posted: Sun Jun 24, 2007 9:30 am

by pvcmaster

I have another question that i need to know before i build this thing. When i open the upper ball valve to fill the secondary chamber, air pressure is going to rush in right? I am not sure if the sprinkler valve is going to seal immediately, or if it needs a slow buildup of pressure to seat the diaphragm, like i think. If the valve cannot seal immediately, does anyone have any suggestions for how to redesign that part of the gun? I appreciate anyones help.

Posted: Sun Jun 24, 2007 3:55 pm

by Acdcmonkey1991

Don't hold me to this but you might loose a little air at first, and then the valve will seal. To fix that, you could just buy a metal ball valve and slowly open it so that it will seal without loosing pressure.

Posted: Sun Jun 24, 2007 9:02 pm

by jrrdw

Mine allways leaks a little weather i fill it fast or slow. Load it last, that way the little bit of air wont push out the ammo.