Page 12 of 61

Posted: Wed Mar 28, 2012 2:05 pm

by Petitlu

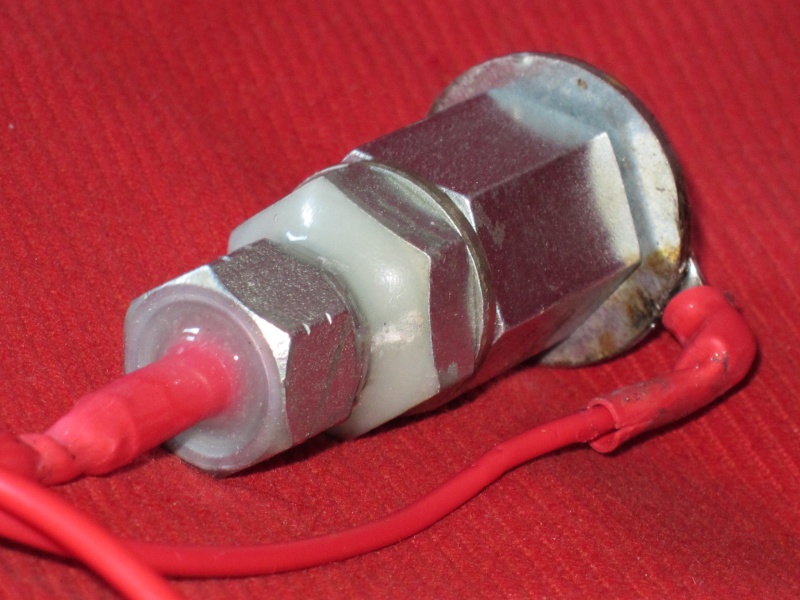

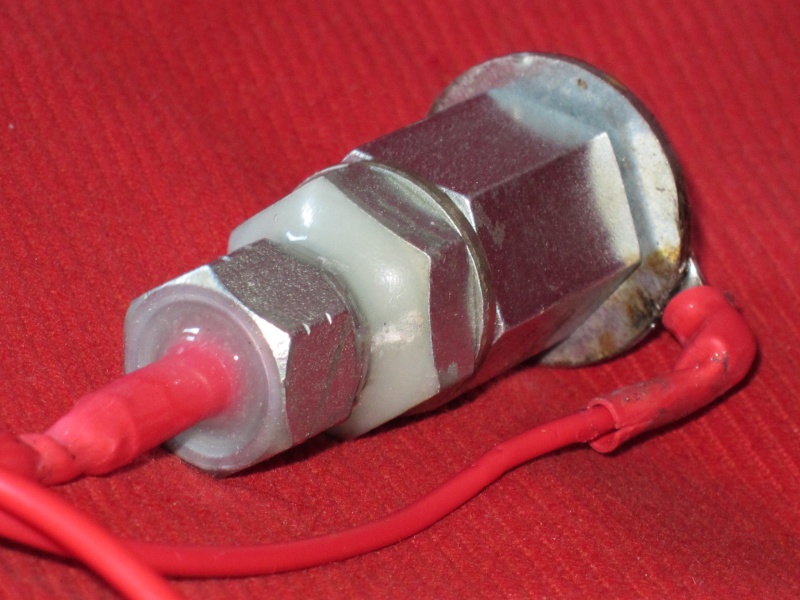

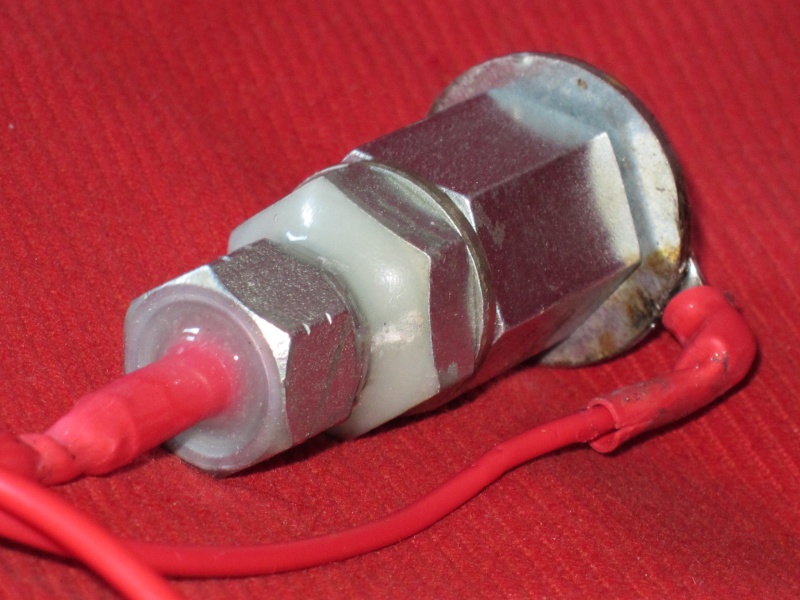

I redid my electrodes hoping to be able to do with my flash Mix40:

I have not done the system of electrodes / / but I opted instead for a plug HM.

You can also see a seal that helps me when I want to unscrew the spark plug to clean it.

I tested this config up to 40bar and no worries, the spark is good.

Posted: Thu Mar 29, 2012 11:27 am

by killerbanjo

Looks nice and clean mate, really looking forward to the finished product

Posted: Thu Mar 29, 2012 11:46 am

by Petitlu

Thank you!

Tomorrow I'm testing at Mix20 and Mix30!

tests will be done with the .50 caliber rifled barrel

and a smooth barrel copper in 12mm caliber (.472) and covered with iron along 100cm (3.28ft)

Posted: Thu Mar 29, 2012 12:27 pm

by killerbanjo

Sweet

looking forward to it

Posted: Thu Mar 29, 2012 12:41 pm

by Petitlu

Me too!

I did rupture disks today with cans of "1664"!

Posted: Thu Mar 29, 2012 12:50 pm

by jackssmirkingrevenge

can you give me the exact diameter of the copper pipe? It's easier to make the sabots for a smoothbore barrel

Posted: Thu Mar 29, 2012 12:58 pm

by Petitlu

Diameter in : 12mm

But in a smooth barrel not rotating the bullet ...

Note with a sphere or an arrow that's not important ...

will support the smooth barrel Mix40?

Posted: Thu Mar 29, 2012 1:04 pm

by jackssmirkingrevenge

Petitlu wrote:But in a smooth barrel not rotating the bullet ...

Note with a sphere or an arrow that's not important ...

Yes, and also there's a lot less friction drag - that's why modern tanks have smoothbore barrels

will support the smooth barrel Mix40?

What's the thickness of the copper?

covered with iron

What does this mean exactly - did you put it inside an iron tube?

Posted: Thu Mar 29, 2012 1:18 pm

by Petitlu

thickness of copper tube: 1 mm

yes I put the copper tube in an iron tube

Posted: Thu Mar 29, 2012 1:18 pm

by jackssmirkingrevenge

wall thickness of the iron tube?

is it an exact fit?

Posted: Thu Mar 29, 2012 1:21 pm

by Petitlu

thickness: 0.8mm

no space between the tubes

weakness is at the connection, the steel tube stops against the brass fitting

Posted: Thu Mar 29, 2012 3:52 pm

by jackssmirkingrevenge

Shouldn't be a problem.

I've done some machining in the meantime, i apologise that the workmanship is quite shoddy and rough, I don't have much free time at the moment - but it should all fit well and give you some good results

There's 5 8mm bearing sabots for your rifled barrel, 4 collars and pusher plates for your smoothbore barrel and 3.4mm diameter nails that should slip on without modification, and two tail sections that would require you to cut the head off the nails.

Posted: Thu Mar 29, 2012 4:09 pm

by Petitlu

Thank you!

I can not wait to test all these shoes!

I will remove the burrs, no problem!

you made multiple versions, it is good

Posted: Thu Mar 29, 2012 4:20 pm

by jackssmirkingrevenge

Petitlu wrote:Thank you!

I can not wait to test all these shoes!

No worries, will post them tomorrow

looking forward to your results.

I'm hoping the centrifugal force on the 8mm sabots in the rifled barrel will help the sabot spread and separate.

I will remove the burrs, no problem!

Don't bother too much, they are going to be fired after all

Thinking about it, it's best if you cut off the heads of all the nails you use, in order to avoid the weight at the back making it tail-heavy. A bit of 5 minute epoxy to keep the nails in place should be enough.

Posted: Thu Mar 29, 2012 4:31 pm

by Petitlu

Nails are striped so they will not go with the epoxy