Page 117 of 443

Posted: Fri Nov 04, 2011 2:17 am

by Zeus

It had me for the first couple of tries, then I thought, clever bastards.

GF, that motor might be a bit fast, have you got access to some pulleys? The ratios won't matter too much, you can compensate with the speed controller the Gippeto suggested. And you can test without throwing shrapnel everywhere.

Also, a long shot, IIRC you live in Florida, do you live around Melbourne? I've got a mate there, as I said, a long shot.

Posted: Fri Nov 04, 2011 5:27 am

by Gun Freak

I was trying to avoid pulleys because of the extra work when I could just use a switch like Gipetto suggested, but if I end up needing to I will. Melbourn... Is about 2 hours away from me.

The card trick was stupid

Posted: Fri Nov 04, 2011 8:00 pm

by Gun Freak

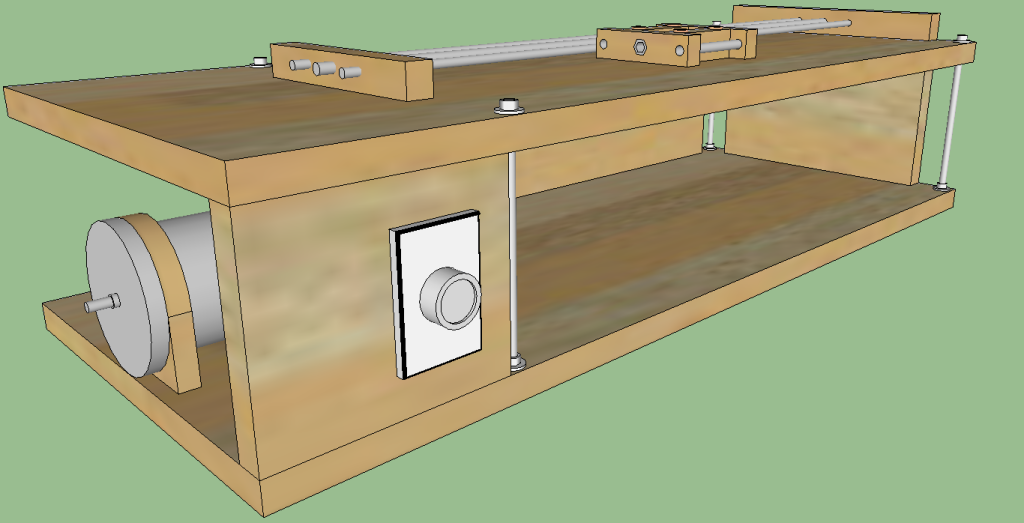

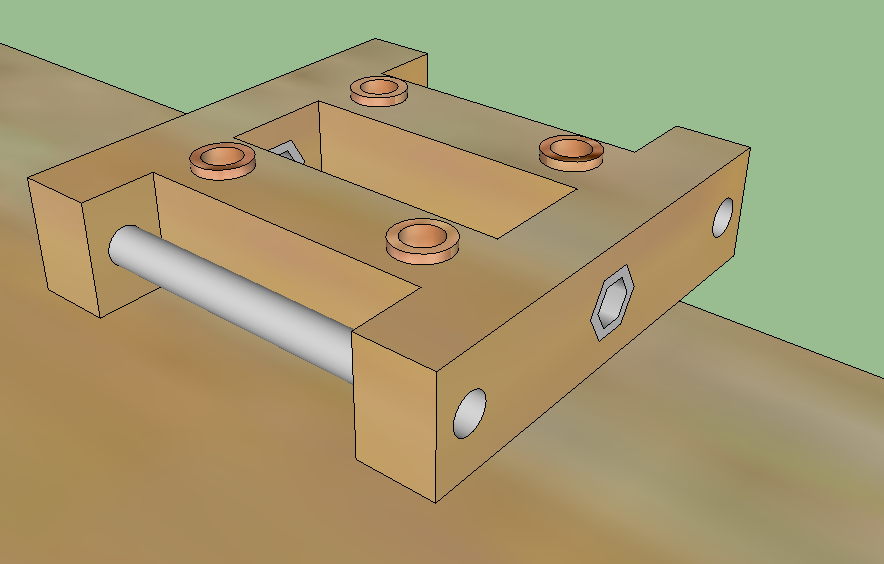

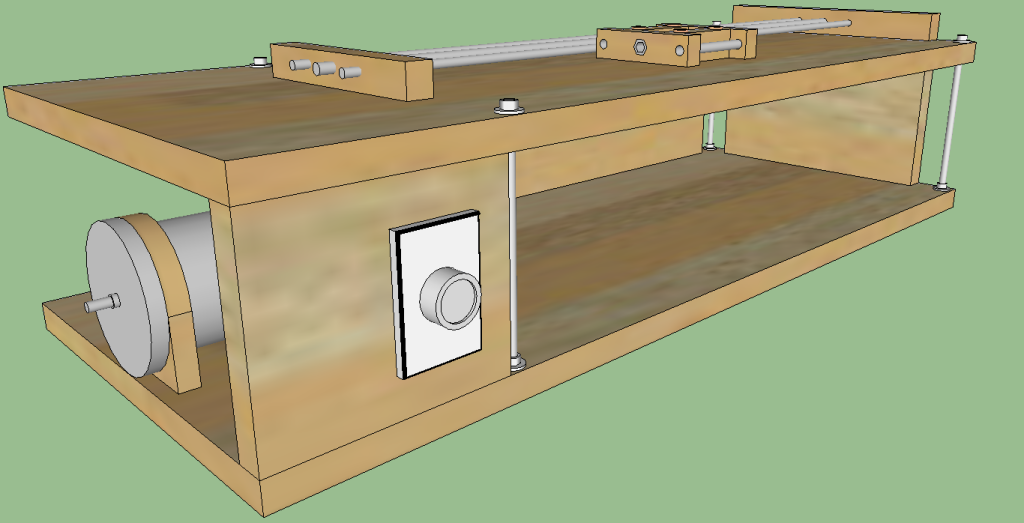

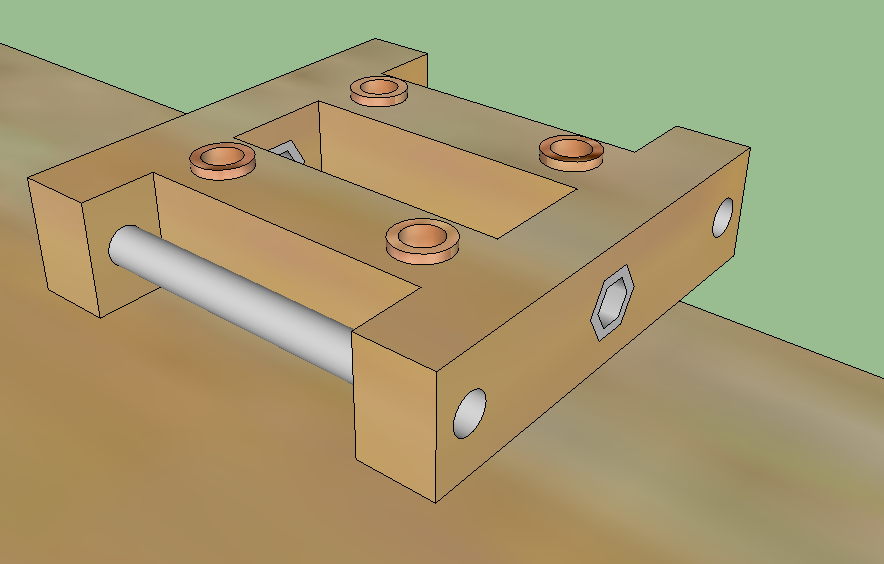

Proposed lathe design sans chuck, bearings, or pulleys. Ignore the inside of the nuts in the middle of the sled thing, they should be circular not hexagonal.

Posted: Sat Nov 05, 2011 10:04 pm

by Daltonultra

Gun Freak, I have to admire your ingenuity. That actually looks like a workable design, if you stick to light-weight project materials. I'd see about picking up a couple cinder blocks to bolt it to, though. The mass will soak up vibration that could otherwise hurt your precision.

Actually, I'm a little jealous, and a lot frustrated... my Dad has my Grandpa's old Atlas metal lathe, and I've been trying to get him to get a new motor for it for the longest. I've even offered to buy the damned thing from him...

Posted: Sat Nov 05, 2011 10:13 pm

by Gun Freak

Another trip to the Depot tomorrow, I may pick up some more lumber and that dial switch to get this thing off the ground (no pun intended). I'm excited to get this thing working. But I still need to sort out the chuck problem. I was thinking a large copper cap but they have thin walls... Ideas anyone?

Posted: Sat Nov 05, 2011 11:25 pm

by jackssmirkingrevenge

Gun Freak wrote:Ideas anyone?

Yes.

Surely you can rustle up that sort of money through a combination of odd jobs, auntie/granny grants, parental lobbying... it's not a Sherline, but at least it doesn't have a wooden bed...

Posted: Sat Nov 05, 2011 11:52 pm

by Crna Legija

why You don't buy a chuck off eBay and make it fit, shouldn't be too hard.

http://www.ebay.com.au/itm/3-jaw-chuck- ... 500wt_1361

that's ones i Australia but I'm sure you can find old one in the usa

On another off topic question do you guys think epoxy putty would be good to filling the scratch marks on car rims? because i can get a set(5) of

22'' pentagons for 250 bucks. they retail for 2500.

I'm going to snatch em up anyway i have found a place that will make them like new for 150 a rim though.

Posted: Sun Nov 06, 2011 5:39 am

by jackssmirkingrevenge

Bloody hell... well, sooner or later they were going to strap explosives to these little UAVs.

[youtube]

[/youtube]

Inflatable wings, carbon fibre body, and

this is what it does to a car door

There might yet be a market for a sentry gun to defend against these things

Posted: Sun Nov 06, 2011 10:53 am

by Gun Freak

I no want to buy a lathe

Just got back from home depot but I didn buy anything because I didn't know what I needed. I determined that belt drive or chain drive will be too complicated so I'm going to do a single level lathe with the motor directly powering the chuck. 120V dimmer switches are 5 bucks so I think I'll use one of those. I need to think about how I'll attach the motor to the chuck through a bearing. The threads on the motor are not standard and only extend out less than 1/2".

Posted: Sun Nov 06, 2011 11:07 am

by Gippeto

Check the ratings on those dimmer switches....might be throwing money away.

I suspect that dimmer switches will regulate the voltage to the item...driving a motor, this will reduce power output as well as speed.

Pulse width modulation will give full voltage for varying lengths of "on" time to achieve speed reduction.

http://www.harborfreight.com/router-spe ... 43060.html

Posted: Sun Nov 06, 2011 11:22 am

by Gun Freak

Hm, it said 120vac on the box...

It's for lights though... wouldn't it still work with a motor?

http://www.homedepot.com/Leviton/h_d1/N ... ogId=10053

Posted: Sun Nov 06, 2011 11:31 am

by Gippeto

Drop Jimmy or Tech a pm...they'll likely know for sure...all I can really say with certainty is that one is intended for lightbulbs...the other for motors.

Dimmer switch is good for 120VAC...at how many watts? What's the current draw of the motor?

I know which one I'd use.

Posted: Sun Nov 06, 2011 11:37 am

by Gun Freak

I searched the internet forever trying to find the motor but couldn't find anything. It says on it 120V and 60Hz. That's all I can say.

Posted: Sun Nov 06, 2011 11:48 am

by Gippeto

120v is "standard" house hold voltage. 60hz is the frequency of the sine wave.(ac voltage operates as a sine wave)

What did you "rescue" the motor from? Manufacturers sticker with a model number on it?

Posted: Sun Nov 06, 2011 12:22 pm

by Heimo

you can drive brushed AC motors from a dimmer switch, but not induction motors, you will damage it (I cannot exactly remember why...)