Page 23 of 51

Posted: Tue Apr 19, 2011 10:17 am

by jackssmirkingrevenge

LeMaudit wrote:

this holes would limit the range? How's that? On the contrary I would have thing they help to stabilize the flight.

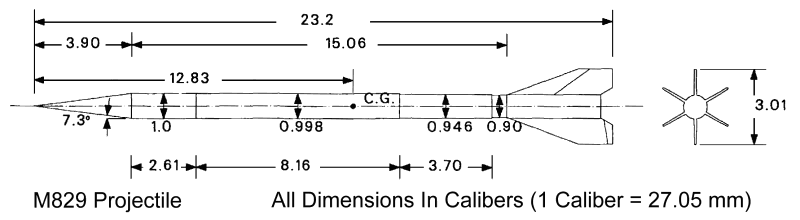

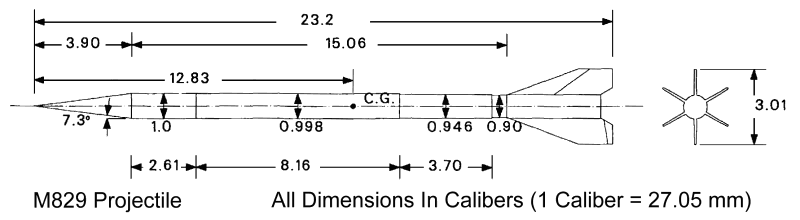

The holes don't limit the range, but the cone stabiliser as opposed to the thin profile fins on the standard projectile (M829 below) limit the range so it can be "safely" (muzzle velocity 3,740 fps!) used for training.

Beautiful holes I say...

Machinist pr0n

Posted: Tue Apr 19, 2011 11:25 am

by dewey-1

LeMaudit wrote:

this holes would limit the range? How's that? On the contrary I would have thing they help to stabilize the flight.

BTW, Beautiful holes I say...

It all comes down to Cd. Coefficient of drag. Much more frontal area than fins.

Knew you would like all the holes!

Posted: Fri Apr 22, 2011 3:11 pm

by dewey-1

Here is a preliminary sabot with the Mini-Boy on separation.

Click to enlarge.

Posted: Fri Apr 22, 2011 9:18 pm

by jackssmirkingrevenge

That looks fantastic Duane! My only concern is that the rear plate might need a little more support if used with a high mix hybrid.

Posted: Fri Apr 22, 2011 9:33 pm

by MrCrowley

What are the estimates for sabot weight? It's looking good though.

Posted: Fri Apr 22, 2011 11:58 pm

by JDP12

Interesting.. What advantages do you see this having over a traditional separating sabot?

My concern with this is that the massive wind resistance the front plate encounters may "skew" it in flight. since the sabot doesn't separate, this may skew the projectile before it separates.

Posted: Sat Apr 23, 2011 12:06 am

by MrCrowley

If that's the case, how hard do you (Le Maudit) think it would be to build the sabot like above but in four parts?

Posted: Sat Apr 23, 2011 12:24 am

by JDP12

If you built that sabot in four parts, I would recommend making each piece wider for more stability in the barrel. I'd still recommend a solid back plug, but making the sabot pieces wider would increase their reliability.

If they are so thin, I cna see them moving around in the barrel around the munition and possibly throwing it off.

Either that, or I would make them lock into the round somehow- an easy way is to machine grooves into the round, and reverse grooves into the sabot, that way the sabot "locks into" the round until it separates.

I would advocate a multipiece sabot, not a one piece. The air resistance would definitely skew a large flat surface such as that one. And since the munition wouldn't leave the sabot immediately, that would throw off the munition's accuracy and trajectory. If it is extreme enough, the munition may not separate, although I doubt that. It would probably still separate, but not in the way intended.

With that design, the munition would have to fit extremely loosely in the sabot, if there is too much friction, the munition won't separate quickly enough so that it is affected as little as possible.

As such, I advocate a 3 or 4 piece separating sabot. This way the sabot begins separation instantly upon exiting the barrel, resulting in very little affect on the round.

See the video below. as you can see, the sabot begins separation instantly.

Granted, its an animation, but the sabot still separates the same in real life.

[youtube][/youtube]

Posted: Sat Apr 23, 2011 7:54 am

by LeMaudit

Yes, great job on the 3D

And this virtual MiniBoy is exactly as the original (I checked

)

the rear plate might need a little more support if used with a high mix hybrid.

We discussed that, and I will increase the thickness. It is 1/16" in the drawing, I'll go for 3/16" in aluminum for the back disk.

What are the estimates for sabot weight?

I'll have to build it to answer this one

The 4 "petals" are UHMW 1/4" thick. The front ring and back plate are aluminum.

What advantages do you see this having over a traditional separating sabot?

Easiness of building, and also weight gain regarding other design considered.

This is JSR design BTW

My concern with this is that the massive wind resistance the front plate encounters may "skew" it in flight. since the sabot doesn't separate, this may skew the projectile before it separates.

You might be right

Having the drag on the back plate only could be better. That is easy to solve fortunately, I only have to make a thin ring (like a slice of tubing) instead of a disk in the front, inserted in 4 thin slots. What do you think?

If that's the case, how hard do you (Le Maudit) think it would be to build the sabot like above but in four parts?

Would be a different design. The 4 pieces would need a better drag than a thin edge to be able to separate quickly, it would be impossible to "link" them for rigidity on the front too.

As such, I advocate a 3 or 4 piece separating sabot. This way the sabot begins separation instantly upon exiting the barrel, resulting in very little affect on the round.

The very first design I though about was a similar sabot. But people seem to have success with more simple cup sabots. This design we propose is a cup sabot, as light as possible while keeping some rigidity. It is also relatively easy to build without specialised equipment, with a bit of creativity one can find a disk of the proper diameter and attach 4 petals to it in various materials. I'll go the full machined way of course

If it doesn't work well, it will not go far, the projectile will be easy to retrieve (hopefully!) and it will be time to make another sabot design

I'm thinking the worst thing that could happen to the MiniBoy is a bending of the fins, and I designed then in a way where they can be easily replaced.

Posted: Sat Apr 23, 2011 7:59 am

by dewey-1

Here is version I that I proposed. It could easily have mating serrations added to the sabot and projectile. The outer shell is slit ABS pipe with a hinge as a pivot point.

Posted: Sat Apr 23, 2011 8:13 am

by LeMaudit

Here is version I that I proposed. It could easily have mating serrations added to the sabot and projectile. It outer shell is ABS pipe.

my concerns about this design were a lot more friction (the 2 sides would be pushed very hard on the barrel wall when the shot pressure is on the hinge), more weight, and possibly an unbalance during the opening if the tail tip was touching the hinge.

Also, as the MiniBoy cannot be pushed hard from the tail tip (it's the weakest part of the thing), it would need support from the conic part. To solve that, friction, support, it needs more complex fittings that will negate IMO the simplicity of the original drawing and increase even more the weight.

I also think the hinge would rip apart due to the stress. But that could be experimented

Oh, and it's not that easier to light a magic string

Posted: Sat Apr 23, 2011 8:36 am

by dewey-1

LeMaudit;

I am reviewing and revamping the design to prevent tail cone from any stress.

Also looking at reducing friction area of ABS pipe by turning down diameter in certain areas.

Another possibility other than serrations is to use 4 small pins and dimples on projectile.

Posted: Sat Apr 23, 2011 8:47 am

by LeMaudit

Cool

The beauty of using UHMW is that it is a low friction material by itself.

Posted: Sat Apr 23, 2011 8:51 am

by jackssmirkingrevenge

My original idea was to have just the back plate as per attached diagram.

To ensure easy separation, the forward tips of the longitudinal members could be of slightly larger diameter that the bore, in such a way that they grip the projectile while in the barrel then spring out when it leaves the muzzle.

A bit like firearm sabots with much less movement

Posted: Sat Apr 23, 2011 9:03 am

by LeMaudit

My original idea was to have just the back plate as per attached diagram.

Very true JSR, sorry I forgot.

But if the grip open earlier (just like for dewey-1 sabot), the projectile will slow down while the sabot is still accelerating, risking to touch the tail and unbalance it. I'm not sure if I'm clear, this challenge my linguistic capabilities

Were are my pencils....

this holes would limit the range? How's that? On the contrary I would have thing they help to stabilize the flight.