Posted: Tue Sep 11, 2012 8:11 am

Agreed!jackssmirkingrevenge wrote: Sometimes you need an arsehole to say the things everyone else is too polite or tactful or afraid to say, it's a necessary evil.

Agreed!jackssmirkingrevenge wrote: Sometimes you need an arsehole to say the things everyone else is too polite or tactful or afraid to say, it's a necessary evil.

I love being that guy!!!!Gippeto wrote:Agreed!jackssmirkingrevenge wrote: Sometimes you need an arsehole to say the things everyone else is too polite or tactful or afraid to say, it's a necessary evil.

That would corrode beyond repair on its first use.MrCrowley wrote:I was left wondering the same thing all day. Can't you just use a precise gauge that is open to the water?

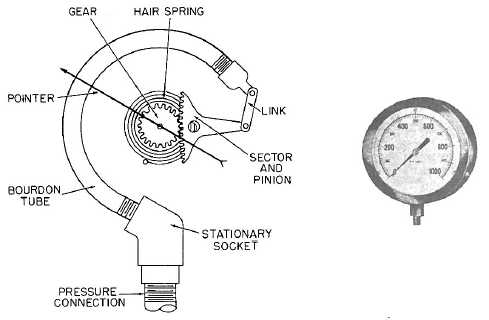

unless that gauge was sealed, and the hardware store type aren't, the needle wouldn't move at all because the water pressure would be pressing on the <strike>little piston</strike> bourdon tube inside of the gauge and on the syringe essentially canceling each other out. I actually like the original Idea though you might want to drill some ports in the steel casing of the gauge so the pressure doesn't crush the glass because it couldn't equalize fast enough.why not connect the gauge to the nozzle end of a syringe, and cut down the plunger so that just enough is left to keep the seal steady? That way as you go down the pressure increase will compress the plunger, increasing the reading on the gauge.

That doesn't sound right because they have different areas...pneumaticcannons wrote:unless that gauge was sealed, and the hardware store type aren't, the needle wouldn't move at all because the water pressure would be pressing on the little piston inside of the gauge and on the syringe essentially canceling each other out.

Forgot about that little tidbit, lolThat doesn't sound right because they have different areas...

I had no idea that it is actually called a "bourdon tube". I learned something todayAlso, what "little piston"?

My suggestion assumed the gauge was sealed... I would just encase the gauge in a block of epoxy et voilapneumaticcannons wrote:Though the needle movement would be minimal because water pressure still is pressing against the bourdon tube... unless you used a really wide syringe.

Thinking about it your quite right... I think i would have to have a piston.jackssmirkingrevenge wrote:I don't get the physics here.

If you have 2 bar in an incompressible tube, why should this pressure reduce as you go deeper?