Posted: Sun Jan 13, 2008 9:31 pm

I'm with nsane, even with the diagrams i cant figure out what is pushing the barrel back after each shot. Someone help me...

Your Spud Cannon Community

https://www.spudfiles.com/

Hey thnx for drawing it out and bringing it here! Its a very good idea, I have been drawing it on paper but I dont seem to get a good breech/loading system. This way it could be automatic yeah, but I experienced that it cycles way too fast. So yeah getting the balls in the barrel is next. If I have time I will try to make something like on your picture but then without a loading hole''. The problem is that for everything to be balanced out the pressure has to stay constant (within 0.5 atm) to reload and as the barrel has a smaller area then the valve it makes a even smaller margin. I work at 8atm coke bottles so I cant achieve constant pressure''. So yeah we will work on this.nsane-spuds wrote:I was thinking how it could be possible to acomplish full auto with your desing while keeping it as simple as possible and I came up with this... What do you think?

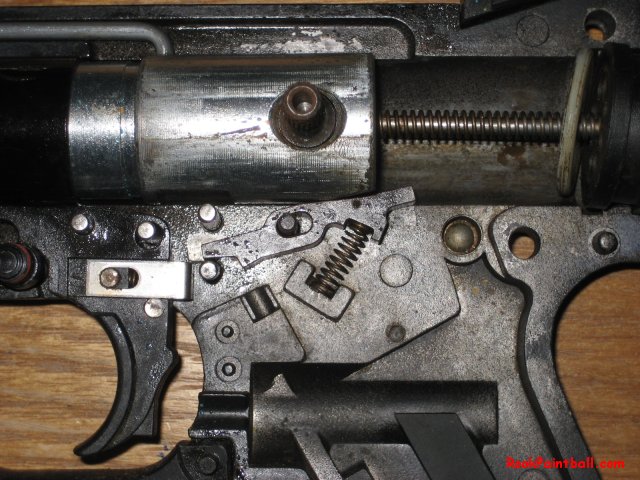

My gun doesnt really cycle itself back, u have to do it by hand. Nsane drew out this idea of an automatic reload working. I guess I cant call mine semiauto then.FordGtMan wrote:I'm with nsane, even with the diagrams i cant figure out what is pushing the barrel back after each shot. Someone help me...

I would buy it! Its a nice price. Just becarefull bc most paintball regulators have an output pressure of about 23bars. So my advice is to put a stronger spring in the regulator to work at a pressure of about 8 bars. The higher the pressure the more energy your hammer needs, and thus more wear (as I use alunium pipping). I dont think we should make this design auto rather semi, I have been looking at simple tippmann triggers:nsane-spuds wrote:Wow, this program looks very interesting... can it simulate air pressure?

Well, to get the bbs in the barrel fast enough, we could use a spring loaded magazine but, it eould run out of ammo rather fast... so maybe we could use a airsoft hi-cap mag... some of them hold up to 600 bbs.

The only thing that I am really worried about with my desing or with anny full-auto is that it will empty a coke bottle really fast ( I think) so... Im thinking of buying my self a co2 paint ball tank and a regulator, my freind is willing to sell me his set up for 40$

Plz check the movie I posted and the detialed pictures, I also made this animation to make things clear. Plz look at those to get the insight. At the moment I dont have time to make a detailed drawing or instructions. I think the main thing is getting the materials I used, once u have those start making the valve. So yeah go from there for now.ajdevi92 wrote:yeah every one please reply i want to see the plans of this so bad i wana make one now!!! lol great gun ! can you make like a diagram thingy on how to make the parts and what parts go where please

Hey I just posted the materials that were used and its dimensions. So check this blog on pg1 at the top. The pipe sizes are not that important though. Its important that the oring u put in seals, so it must be a bit bigger then the pipe it is put in. If it still doesnt seal, try to give the valve spring more pretension. I find it a good start that u started with the valve though, bc once u get over that u can design the rest urself. Btw if u really have problems just post some pics so I can give u advice as I dont know what ur situation is.ajdevi92 wrote:i spent bout 6 hours today on this trying to make this but my valve keeps leaking and its annoying the crap outta me could you please tell the different sized pipe and what kind of metals the pipes are made from would be mutchly appreciated

thanks

no worriez i will try again tomorrow because i really want this to worki have been looking for this kind of valve system for a loooooooooonnnnnnnnnngggggg time lol thanks yeah i will post pictures tomorrow some timeant wrote:Hey I just posted the materials that were used and its dimensions. So check this blog on pg1 at the top. The pipe sizes are not that important though. Its important that the oring u put in seals, so it must be a bit bigger then the pipe it is put in. If it still doesnt seal, try to give the valve spring more pretension. I find it a good start that u started with the valve though, bc once u get over that u can design the rest urself. Btw if u really have problems just post some pics so I can give u advice as I dont know what ur situation is.ajdevi92 wrote:i spent bout 6 hours today on this trying to make this but my valve keeps leaking and its annoying the crap outta me could you please tell the different sized pipe and what kind of metals the pipes are made from would be mutchly appreciated

thanks

Hey plz use this animation for now, as if I make a video u wont be able to c the internals anyways.ajdevi92 wrote:hey do you reckon you could please post a video of you pulling the trigger and recocking the barrel so i can see exactly how it works please please

not exactely what i mean but yeah just a video of the out side showing you cocking the barrel and then pulling the trigger like you did with the other one stacked tube or somthingant wrote:Hey plz use this animation for now, as if I make a video u wont be able to c the internals anyways.ajdevi92 wrote:hey do you reckon you could please post a video of you pulling the trigger and recocking the barrel so i can see exactly how it works please please

[youtube][/youtube]nsane-spuds wrote:I was thinking how it could be possible to acomplish full auto with your desing while keeping it as simple as possible and I came up with this... What do you think?