Page 4 of 10

Posted: Wed Oct 12, 2011 6:35 am

by Ragnarok

danielrowell wrote:It would be interesting to see what would happen if GL was tested with a boat tail.

Probably relatively little. The round shape exhibits something similar to supercavitation, where it just smashes the air out of the way and flies in a little bubble of vacuum.

This reduces skin drag (a big factor with long walled projectiles at subsonic velocities) and causes a reduction in turbulence off the hard edges at the base of the projectile (the same thing a boat tail sets out to do).

Adding a boat tail wouldn't have as much effect as it does on a longer nosed bullet (which will have a laminar boundary layer around the nose and body).

One other method of reducing drag that is interesting, although not shown on the graph, is how much reducing the coefficient of friction of a projectile's surface can improve its drag coefficient.

Posted: Wed Oct 12, 2011 7:38 am

by al-xg

I was thinking about this during my fase REM, that small diameter Delrin taper at the end is going to be a bitçh an interesting challenge to machine...

It might require machining in stages, starting with the tip then moving up.

Or maybe it should not end in such a pointed tip so you can use the tailstock. I'm guessing you're worried about it flexing ?

You could even drill out the centre and put some steel rod in there whilst machining it. Would make it lighter too once removed...

Posted: Wed Oct 12, 2011 1:06 pm

by danielrowell

Whoops, double-post.

Posted: Wed Oct 12, 2011 3:30 pm

by danielrowell

Radnarok wrote:One other method of reducing drag that is interesting, although not shown on the graph, is how much reducing the coefficient of friction of a projectile's surface can improve its drag coefficient.

You might find this interesting, then. Did you know that the skin of dolphins actually reduces their Cd?

When physicists compared their calculations with actual tests, they found that dolphins have a better Cd (0.0036 for wetted frontal area) than they calculated. It turns out that this is caused by their skin, which is very soft, flaky, and "wavy." This "waviness" reduces a lot of the friction around the dolphin, but it's not the only contributing factor. Dolphins shed their skin once about every two hours, and the pieces which flake off actually disturb vortices around the dolphin. Here are two articles on the subject:

http://www.springerlink.com/content/u514r0p04321vg35/

http://www.sciencedaily.com/releases/20 ... 072242.htm

I know that this is in the realm of fluid dynamics, but it would be interesting to know if this would work to some extent with projectiles, kind of like how the dimples on golf balls reduce air friction.

And no, I'm not suggesting that we rip the skin off of dolphins and attach it to projectiles...

Posted: Wed Oct 12, 2011 5:28 pm

by saefroch

So I hear you guys like patents. Have you considered

DLC?

Posted: Wed Oct 12, 2011 7:43 pm

by danielrowell

saefroch wrote:So I hear you guys like patents. Have you considered

DLC?

Patent use words me no understand!

There, that's better. 8)

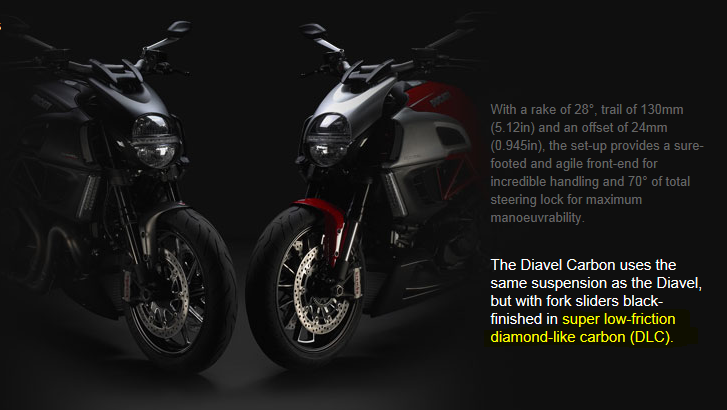

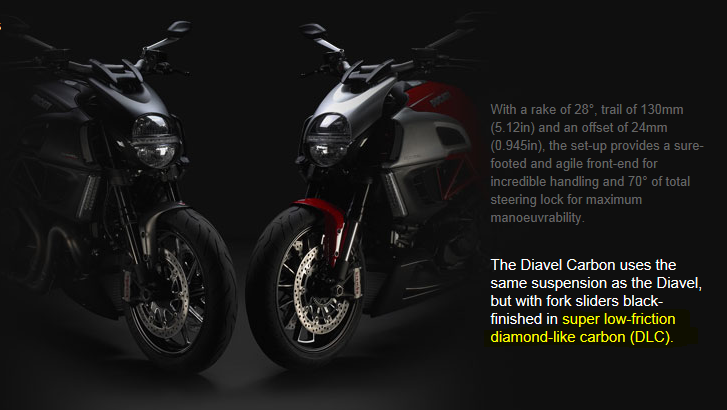

And yes, by a rather remarkable coincidence I was just looking at Ducati's new Diavel on the same day that you posted about DLC. I'd never heard of the stuff before now, honest.

Posted: Wed Oct 12, 2011 9:00 pm

by POLAND_SPUD

I'm not suggesting that we rip the skin off of dolphins and attach it to projectiles

I found that the simplest solutions are usually the best ones too

@danielrowell

while this stuff is indeed interesting the crucial thing here is that around 99% of projectiles ppl use for spudgunning doesn't come close to what could be achieved with a stable GL shape, not to mention G8 or G7

Posted: Wed Oct 12, 2011 10:34 pm

by danielrowell

POLAND_SPUD wrote:

while this stuff is indeed interesting the crucial thing here is that around 99% of projectiles ppl use for spudgunning doesn't come close to what could be achieved with a stable GL shape, not to mention G8 or G7

Very true, sorry that I went a bit overboard. I'm just really interested in aerodynamics.

Posted: Thu Oct 13, 2011 12:22 am

by jackssmirkingrevenge

It might require machining in stages, starting with the tip then moving up.

Or maybe it should not end in such a pointed tip so you can use the tailstock. I'm guessing you're worried about it flexing ?

You could even drill out the centre and put some steel rod in there whilst machining it. Would make it lighter too once removed...

If I start with 12mm rod, make the taper first then turn the cylindrical part down to 6mm it should be fine, working close to the chuck.

POLAND_SPUD wrote:I found that the simplest solutions are usually the best ones too

That would be fuçking awesome!

Posted: Thu Oct 13, 2011 12:43 am

by Moonbogg

I would be willing to test projectiles, but with a hybrid. Before my next build is done I will get a chrony and can do some consistency testing to arrive at an average deviation value which can be used to give any final projectile a velocity with a plus minus certain percentage based on that average value. I'd have to drive out to a dried up river bed about 3 hours away, but hey, its for the community!

Posted: Thu Oct 13, 2011 12:53 am

by jackssmirkingrevenge

Sweet, will you be able to turn the projectiles yourself? The ones I originally posted have endcaps can be made very easily on a lathe and can be popped into suitable lengths of pipe.

Making the tail section out of acetal would ensure it is both light weight and - based on testing I've done - will not burst into flames when exposed to the propelling gasses.

Posted: Thu Oct 13, 2011 1:04 pm

by jackssmirkingrevenge

I made a healf-hearted attempt at a projectile that ended up looking a bit

and is probably the worst thing I have ever machined to do date - still, the proportions were good enough for a quick test, but the results were extremely discouraging.

The inset shows the impact hole in a sheet of cardboard 10 metres away from the muzzle, I shot this out a 300 psi 6mm piston launcher. It was clearly travelling sideways when it hit, this is not looking like it will work.

The CP is to the rear of the CG, but clearly not far back enough to stabilise the projectile.

Posted: Thu Oct 13, 2011 1:24 pm

by Labtecpower

That isn't going to work.

How on earth did you get the head that bumpy

How about a carbon fiber tube tail? that should give a better COG

Posted: Thu Oct 13, 2011 2:06 pm

by jackssmirkingrevenge

Labtecpower wrote:That isn't going to work.

How on earth did you get the head that bumpy

Indifferent use of the compound slide, I made this in a hurry and wasn't really making the effort

How about a carbon fiber tube tail? that should give a better COG

I want to try a length of aluminium tube as the body then play with endcaps as per the drawings in the first post.

Posted: Thu Oct 13, 2011 2:32 pm

by POLAND_SPUD

but clearly not far back enough to stabilise the projectile

I was expecting that

drill out the delrin tail

though to be honest I think you need something even lighter

EDIT

hmm

isn't it what we wnat to achieve ??

and this (a 16mm drag stabilised rocket projectile)

from here >

http://ast.latech.edu/rocketbullets.html

and is probably the worst thing I have ever machined to do date - still, the proportions were good enough for a quick test, but the results were extremely discouraging.

and is probably the worst thing I have ever machined to do date - still, the proportions were good enough for a quick test, but the results were extremely discouraging.