Page 6 of 165

Posted: Sat Feb 23, 2008 6:54 pm

by BigGrib

In the world of Spuds today, I've been thinking about making another advanced combustion, just to have another one around, but while I was being impatient I accidentally glued the 4 to 2 bushing in the coupler backwards and before I could do anything about it, the glue had set enough to where i couln't get it out. So that got me thinking and rather than throw away 6 bucks i decided to make it a co-axial launcher.

The only modification I'm going to have to do is hone the lip on the bushing out. I was planning on making it another camlock setup so I can interchange barrels but then that would kind of take away from the coaxial aspect of it unless I sleeve a GB barrel into the sch80 2". I was however wondering when making a co-axial combustion how do you support the barrel on the inside or do you just let it fly. my reason for this is that the barrel is gonna stick out at least 3 to 4 feet from the chamber and I dont want that extra weight screwing something up and tweaking it.

Posted: Sat Feb 23, 2008 7:15 pm

by DYI

In the world of spuds today, I tested 24 layer 2" alu. foil burst disks, which burst exactly when they were supposed to, at 160 psi. I have a video (as always, I document every firing of the SCTBDC), but it's nothing more exciting than 55 seconds of waiting followed by a loud boom and the camera falling over, so I'm not going to post it.

Posted: Sat Feb 23, 2008 7:20 pm

by Novacastrian

All of my co-ax's have no support for the barrel on the inside of the chamber, apart from my clear pneumo. *Goes to find pic*

I suggest supporting it like this (look at the front of the chamber).

Posted: Sun Feb 24, 2008 1:48 am

by A a r o n

In the world of spuds today...

golfball gun time.

Posted: Sun Feb 24, 2008 2:06 am

by Novacastrian

A a r o n wrote:In the world of spuds today...

golfball gun time.

That valve looks spectacular, don't you screw it up now- the valve gods will hurt you.

Posted: Sun Feb 24, 2008 2:28 am

by A a r o n

I promise I won't screw it up. It's too beautiful to damage.

SDR 21 1.5" and Sch 40 1.5" have the same OD right?

Posted: Sun Feb 24, 2008 3:00 am

by jook13

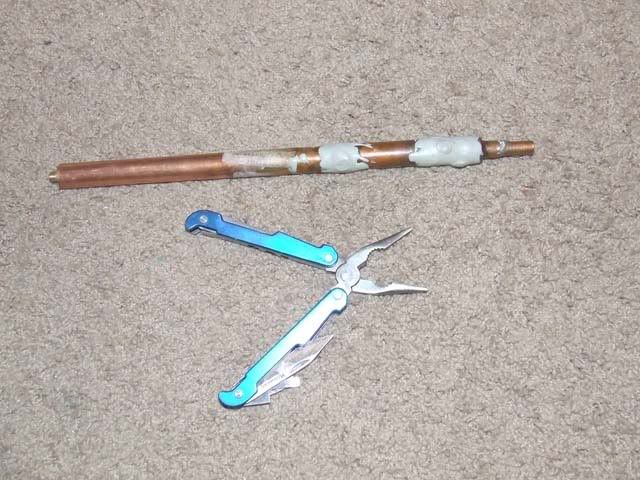

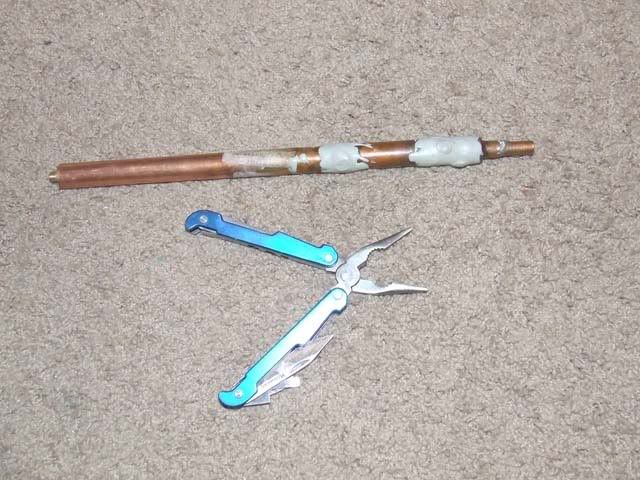

in other news I tried to make a piston valve for the first time. it was very un-impressive, but it still works... shoots about 18 feet at the most (at 250 psi). But, its a learning process, right?

All the jb weld is from when I tried to take it apart and fix it. Now it shoots the same as before and leaks....

Posted: Sun Feb 24, 2008 3:06 am

by MrCrowley

That looks like a very weak JB-Weld mix, did you mix the portions evenly?

Also I find it best to leave JB-Weld to dry for atleast a week for it to reach full strength, nevermind the 24hours recommendation. How long did you leave yours?

JB-Kwik dries full strength within 24hours, so use that if you're impatient.

Posted: Sun Feb 24, 2008 3:10 am

by jook13

sorry... I realised that it wasnt jb weld. That is an epoxy I had around the house. I know jb weld turns out much darker than that... my mistake, I use so much of each that I got confused...

I guess the point of my post was the gun wasnt worth starting a thread over but I wanted to show that I am trying pistons. I will get it right eventually (soon).

Posted: Sun Feb 24, 2008 3:14 am

by MrCrowley

It is a small gun, what were you trying to shoot?

Posted: Sun Feb 24, 2008 3:19 am

by jook13

a small 1/4 inch thick piece of potato. It didnt seem right because way more air left the schrader than the barrel when I triggered it. I had a small pilot volume (piston travels about 3/16 of an inch). I am guessing that the piston wasnt tight enough so too much air got around it.

Posted: Sun Feb 24, 2008 3:22 am

by MrCrowley

Your piston must be too loose of a fit in the pipe, lacking lubricant or is getting jammed up a bit, or all three.

Posted: Sun Feb 24, 2008 3:24 am

by jook13

yeah, It is plenty lubed, so I think its one of or both of the other two. oh well, I am only out like 15 bucks. and I learned a lot.

Posted: Sun Feb 24, 2008 5:02 am

by Hubb

Some of my news:

I found that if you grind a lid to a Gatorade bottle, it fits perfectly in a 1 inch union and makes for a helluva burst disk. To seal, simply put a layer of teflon around the grinded lid.

I've also found that lots of my friends are more than willing to give me there Gatorade lids (I have about 50 so far).

Posted: Sun Feb 24, 2008 10:18 am

by DYI

What pressure does it burst at in a 1" union? The only problem I can see arising is that while you can simply buy 100' rolls of aluminum foil, you have to get Gatorade lids from Gatorade bottles.