Page 6 of 11

Posted: Fri Sep 25, 2009 2:51 pm

by Hubb

The fueling can be simple or complicated. The simplest way I can think of at the moment is to use an idea proposed by FeLeX from back in the day or something similar to a Gen 3 hybrid that DR built.

In these devises, a simple 1x mixture is added to an outside chamber, then this mixture is compressed to obtain the correct mix. By making the outside chamber a certain volume, it should be easy to obtain several charges from this.

Some sort of small check valve, such as a schrader, can be used to add the mixture to a shell.

Posted: Fri Sep 25, 2009 4:08 pm

by POLAND_SPUD

a green gas can and fill it with air and mix it in and there you go portable fuelling and firing.

I doubt that valves used on lighters and green gas guns can handle 10X mix repeatedly... so a shrader would be better

The "projectile sealing" cartridge

although I understand that it has some advantages I am not sure how would you replace ammo... that has to be done before fuelling and the system must provide a good seal as soon as the cartridge is filled with a new mix....

I think that I've seen one of your designs that featured a burst disk and a home-made in-built burst disk holder (utilizing threaded joints)

with it you could load cartridges with whatever ammo you want... it would only have to have a length of pipe to accommodate ammo

EDIT

pic added

of course I don't want to use iron on this.... that was just in reference to 1" nominal size threads

Posted: Fri Sep 25, 2009 4:39 pm

by jackssmirkingrevenge

POLAND_SPUD wrote: I think that I've seen one of your designs that featured a burst disk and a home-made in-built burst disk holder (utilizing threaded joints)

From

here?

I had this bit custom made:

This was the finished result:

Posted: Fri Sep 25, 2009 4:49 pm

by Brian the brain

Why not use an onboard high pressure pump like on a Benjamin airgun to draw in the mix and compress it.

All you would need is a checkvalve to insert the mix, then compress.

just make a 1x mix, keep a fan running and pump away.

The pumphead would just not get a checkvalve that;s all..

Posted: Fri Sep 25, 2009 5:40 pm

by Pookydarts

I like it! All of it!

The german anti-aircraft gun linked by jsr reminded me of a falling block action turned 90 degrees to operate sideways. (What's up with that...

)

With a cartridge over a foot long a conventional bolt action would be more than two feet from rear of action to start of barrel, so i was thinking a short-throw bolt that contained only the last 1" of cartridge, thus the cartridge would have to be able to withstand the entire pressure of combustion.

But!

Falling blocks are famous for allowing a few extra inches of barrel because the action is so short, this could allow the launcher to contain a steel (or whatever) 'chamber' that could be fed with much lower pressure rated (read, a sh!?l0ad lighter AND cheaper!) cartridges made of 18 bar pressure rated PVC or something similar.

What do you recon?

Posted: Fri Sep 25, 2009 7:42 pm

by al-xg

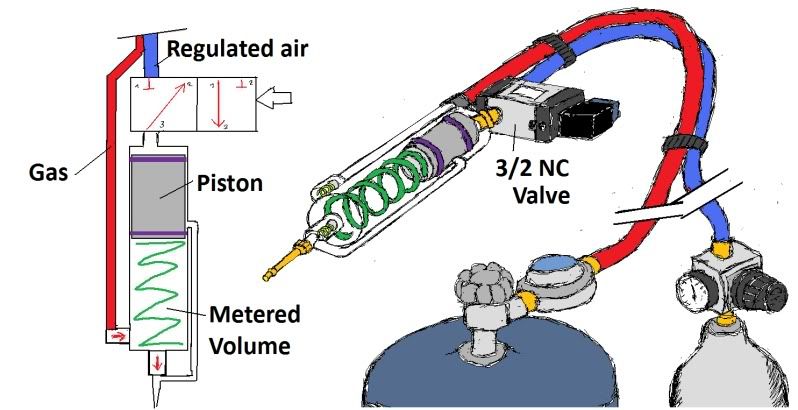

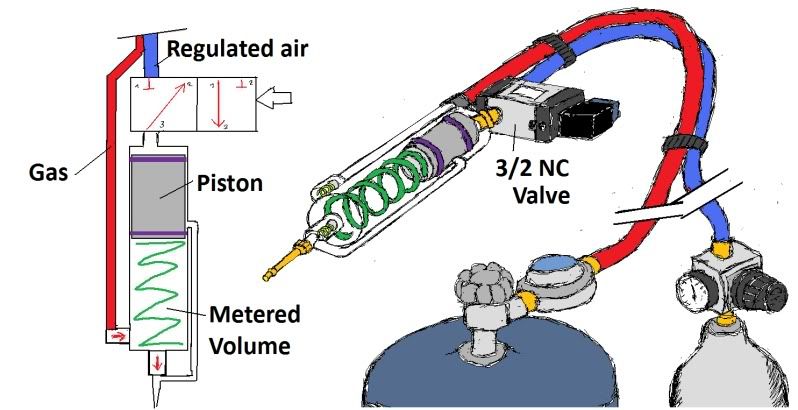

Maybe a safer way of filling cartridges quickly to the right mix ?

This should provide semi automatic filling, just attach the cartridge and activate the 3/2valve to get the right mix.

The drawing shows a pin like connector like the ones used to blow up footballs, but an other type of quick connector could be used instead.

The metering chamber contains the right amount of gas, and the air supply is regulated to the pressure of the mix.

If the gas pressure is high the check valve should have a higher minium operating pressure.

Posted: Fri Sep 25, 2009 8:17 pm

by Technician1002

al-xg wrote:Maybe a safer way of filling cartridges quickly to the right mix ?

This should provide semi automatic filling, just attach the cartridge and activate the 3/2valve to get the right mix.

The drawing shows a pin like connector like the ones used to blow up footballs, but an other type of quick connector could be used instead.

The metering chamber contains the right amount of gas, and the air supply is regulated to the pressure of the mix.

If the gas pressure is high the check valve should have a higher minium operating pressure.

That may work for metering liquids, but gas is compressible. A spring and piston is not needed. This is the basis for a meter pipe on a combustion.

Posted: Fri Sep 25, 2009 8:30 pm

by al-xg

The spring, piston and 3/2 valve are just for automation purpouses really.

Wouldn't be of much use on a combustion as it runs on comrpessed air, but as the hybrid will be needing that anyway...

I cant see why compressability is an issue, as long as the check valve opens, the gas will be pushed out.

Posted: Sun Sep 27, 2009 8:54 am

by psycix

Brian the brain wrote:Why not use an onboard high pressure pump like on a Benjamin airgun to draw in the mix and compress it.

All you would need is a checkvalve to insert the mix, then compress.

just make a 1x mix, keep a fan running and pump away.

The pumphead would just not get a checkvalve that;s all..

Two separate pumps: one for fuel, one for air.

We're not going to compress our fuel mixture in a pump, could go boom.

A pump does however drop the need for a tank of compressed air, so that's good.

Posted: Sun Sep 27, 2009 10:28 am

by Technician1002

psycix wrote:Brian the brain wrote:Why not use an onboard high pressure pump like on a Benjamin airgun to draw in the mix and compress it.

All you would need is a checkvalve to insert the mix, then compress.

just make a 1x mix, keep a fan running and pump away.

The pumphead would just not get a checkvalve that;s all..

Two separate pumps: one for fuel, one for air.

We're not going to compress our fuel mixture in a pump, could go boom.

A pump does however drop the need for a tank of compressed air, so that's good.

With a tracking regulator (mentioned elsewhere) the pumped air driven through a metering orifice could be mixed on delivery with fuel regulated to the air pressure. One stroke or ten, the delivered mix would be proper. It would require modification of a propane regulator to track the air pressure. A normal BBQ 11 inch water column regulator can be modified by removing the spring and replacing the spring with the pump air pressure. An old welding gas regulator may be easier to modify.

Posted: Mon Sep 28, 2009 8:27 am

by jackssmirkingrevenge

Pookydarts wrote:The german anti-aircraft gun linked by jsr reminded me of a falling block action turned 90 degrees to operate sideways. (What's up with that...

)

Sliding and falling blocks are basically the same principle, they vary in artillery systems with the degree to which they are automated. In the most basic the cartridge is inserted, block closed manually, then opened manually after firing. It would be cool to have the cartridge eject on firing.

So, cartridges, I see the following options:

- Burst disk

- Piston

- Projectile sealing

It really depends on the materials and manufacturing methods to be used, the last one would be the easiest as there are technically no moving parts, the question is making a seal reliable enough to hold the projectile under pressure and remain airtight.

Posted: Mon Sep 28, 2009 8:32 am

by Hubb

If projectile sealing can be made easy, it would probably be the better option. If not, something similar to DavidVaini's burst disk cartridge would work.

Posted: Mon Sep 28, 2009 1:06 pm

by POLAND_SPUD

@ projectile sealing

there's gonna be a lot of force acting on the projectile... so while I think htat sealing projectiles might work ok on small scale launchers it gets pretty tough to replicate the same mechanism on a larger calibre

Posted: Mon Sep 28, 2009 1:42 pm

by jackssmirkingrevenge

Not only that, but we'd be limited to hard projectiles. In order for it to be tight enough to resist a 10x mix if would have to be hammered in if it's a large calibre. I don't think it would be practical beyond airsoft scale.

If someone with a lathe is chipping in, burst disk cartridges similar to the example I had made would be a practical proposition. I would leave piston designs as the last resort.

Posted: Mon Sep 28, 2009 3:15 pm

by POLAND_SPUD

so what about the design I draw... of course it cartridge could be sleeved in PVC or ALU to keep the same OD... if it was possible to thread the inside of PVC pipe that could be even simpler...

nah wait a second... all you need is a female-female adapter (or pipe with theadeds on the inside)... and short lenghts of threaded alu pipe (pipe nipples) to hold the disk... the you can epoxy that part into a larger pipe