Page 1 of 1

simple pilot valve

Posted: Thu Oct 04, 2007 7:20 am

by Tom

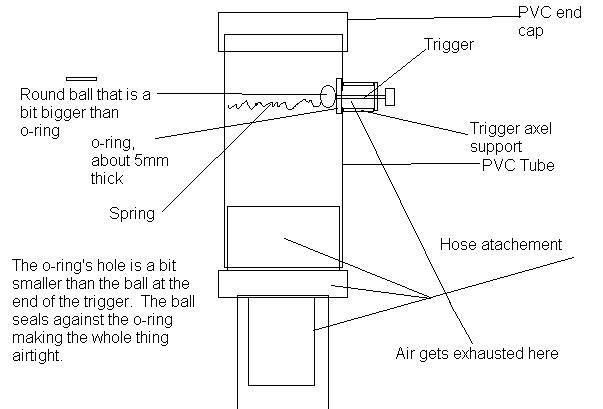

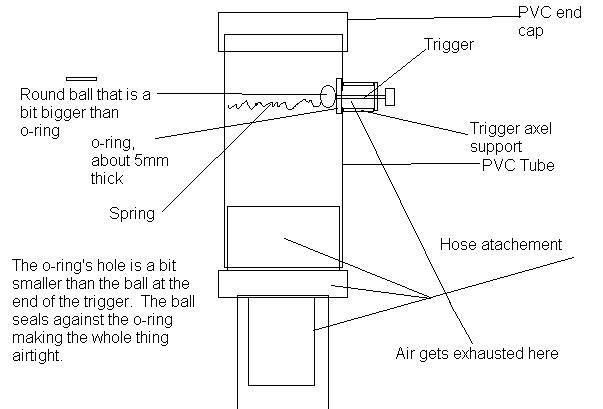

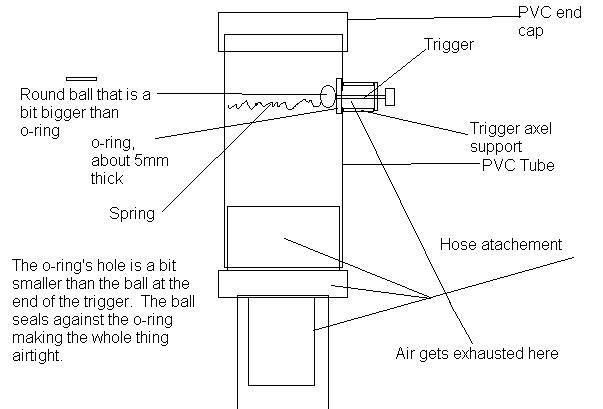

I just desgind a simple pilot valve for my coaxial piston valve that I´m working on. I think i will try to make a housing for the valve, but first I need to find a pipe size that is not to big

.

GR.Tom

Posted: Thu Oct 04, 2007 7:30 am

by jackssmirkingrevenge

This is how blowguns work, why reinvent the wheel?

Posted: Thu Oct 04, 2007 7:38 am

by Marco321

That looks nice, looks hard to make though i think.

jackssmirkingrevenge wrote:This is how blowguns work, why reinvent the wheel?

Same reason you don't see shopping trolley wheels on a race car. You reinvent the wheel to suit new needs. I'm sure the people who made a blowgun didn't intent it to be used as a trigger on a cannon, even though some of them resemble a gun. This persons design uses a blowgun design in a slightly different shaped trigger mechanism to suit his needs. Just like a stone caveman wheel was used and changed to meet the needs of a race car wheel.

EDIT: I might use this on my new cannon

Posted: Thu Oct 04, 2007 7:54 am

by jackssmirkingrevenge

I still fail to see the advantages. This design will be harder on the fingers to operate as you're pushing on the stem directly, not with a lever as with a blowgun. Also, what diameter is the stem part going to be? If it's say, half an inch in diameter and you're using 100 psi, it'll take around 20 lbs of force to activate the trigger, hardly practical if you ask me.

Posted: Thu Oct 04, 2007 7:57 am

by Tom

@Jack.................

My goal is a higher flow rate blowgun, you can purchase a high flow rate blowgun for a lot of cash but you can make wane for less money.

Posted: Thu Oct 04, 2007 8:07 am

by Marco321

jackssmirkingrevenge wrote:I still fail to see the advantages. This design will be harder on the fingers to operate as you're pushing on the stem directly, not with a lever as with a blowgun. Also, what diameter is the stem part going to be? If it's say, half an inch in diameter and you're using 100 psi, it'll take around 20 lbs of force to activate the trigger, hardly practical if you ask me.

I thought you of all people would understand the need to do something like this. Yes the design probably needs work, but how many things have you made 100% perfectly first try? One of the reasons this website is here is to improve on ideas, and you come along and try cut this guy down.

Posted: Thu Oct 04, 2007 8:07 am

by jackssmirkingrevenge

Fair enough, but I recommend you use a lever type trigger to activate it otherwise it will be practically impossible to use.

I prefer to optimise my piston valves in such a way that they don't need high flow pilots, personally it's the more efficient route.

One of the reasons this website is here is to improve on ideas, and you come along and try cut this guy down.

Au contraire, I figured I was being helpful by warning against wasting time and effort on something that in my view wasn't worthwhile, if he wishes to ignore my opinion then he's perfectly free to do so

Posted: Thu Oct 04, 2007 8:15 am

by Marco321

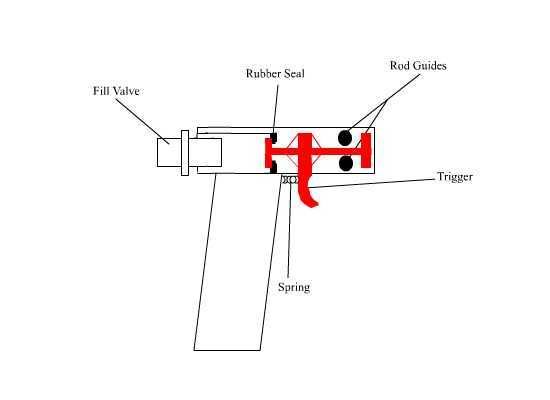

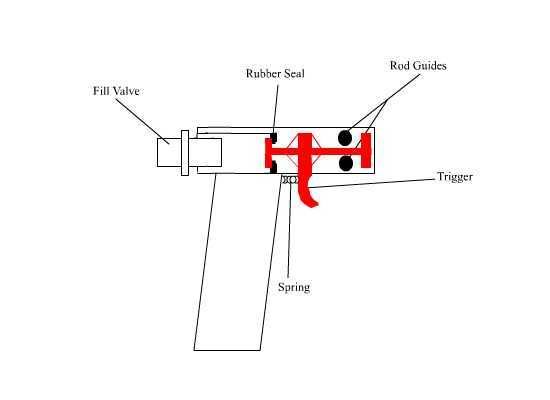

Here is a trigger like blowgun i made, it works well and has a high flow

Posted: Thu Oct 04, 2007 12:52 pm

by Tom

I made a new desgin, the valve itself is simpler than the first. Right now I´m working on the receiver, the valve will come tomorrow (need to buy new pipe). It's just a prototype from wood(the receiver

), if it works good i will make on from plexiglas.

GR.Tom

Posted: Thu Oct 04, 2007 8:27 pm

by Marco321

Hey

You inspired me lol

Here is my design, its a combination of my design and your design.

Some improvements i think i could make is like Jack said, use a lever on the trigger, but i didn't put it in my design simply because it wasn't something i was demonstrating with my design, but when i remake the design after i get some suggestions, i will put it in.

Any comments, criticism, suggestions or questions on my design?

Posted: Thu Oct 04, 2007 10:35 pm

by jackssmirkingrevenge

I think you should look to something like dongfang's work

here where you have two piston disks of the same area meaning your finger doesn't have to fight any pressure, just the drag of the seals.

Posted: Fri Oct 05, 2007 12:40 am

by Marco321

jackssmirkingrevenge wrote:I think you should look to something like dongfang's work

here where you have two piston disks of the same area meaning your finger doesn't have to fight any pressure, just the drag of the seals.

That i believe that is where you are wrong, you see this diagram of this blowgun.

I use have used it on 2 separate guns:-

and

It works perfectly and i push it with one finger. It is not hard at all at 100psi. My design i posted previously on my last post uses the same principal as the one I'm already using, it just has a fancy way of pushing the piston in.

EDIT: My blowgun design works exactly the same way as this blowgun in this picture, i actually pulled it apart and just mounted in a more convenient handle for a spud gun.

I believe, my design and Tom's design will both work well.

Posted: Fri Oct 05, 2007 2:16 am

by Tom

Dam people I just like pneumatics and triggers

. Today I will begin with the valve, there where some problems with the receiver. My goal was hiding a 32MM piston valve in the upper receiver, i must look a bit realistic. Well this weekend I hope I can work on the piston valve.

GR.Tom

Posted: Fri Oct 05, 2007 3:30 am

by jackssmirkingrevenge

That i believe that is where you are wrong, you see this diagram of this blowgun.

If you have a 5mm thick opening then the pressure at 100 psi will only be around 3 lbs, in which case it's fine - but I understood here that since the point here was to improve on a blowgun, you'd want a rather bigger flow.

Posted: Fri Oct 05, 2007 7:40 pm

by Marco321

jackssmirkingrevenge wrote:That i believe that is where you are wrong, you see this diagram of this blowgun.

If you have a 5mm thick opening then the pressure at 100 psi will only be around 3 lbs, in which case it's fine - but I understood here that since the point here was to improve on a blowgun, you'd want a rather bigger flow.

ohh right, i see what you mean. My quest is for a realistic looking trigger lol, i probably should of said that... my bad

But yeah you are right in saying if i have a huge hole it will be hard to push the piston back. But i guess if i wanted lots of flow, a spring powered ball valve pilot would probably work well.

.

.