Page 1 of 1

8mm Copper Piston Valve Gun Help

Posted: Sat Oct 13, 2007 1:01 am

by Marco321

Hey

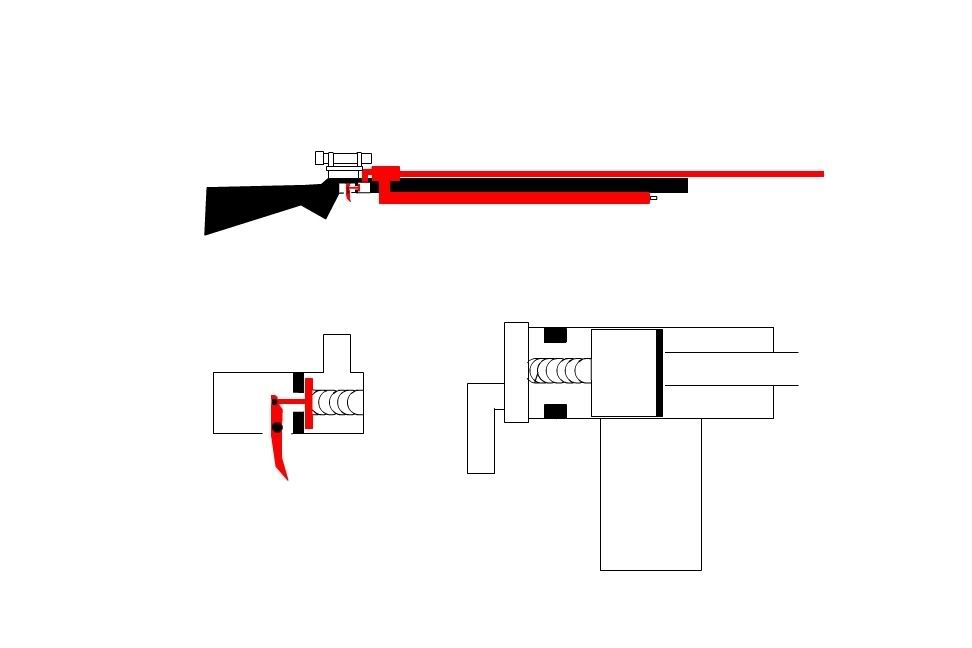

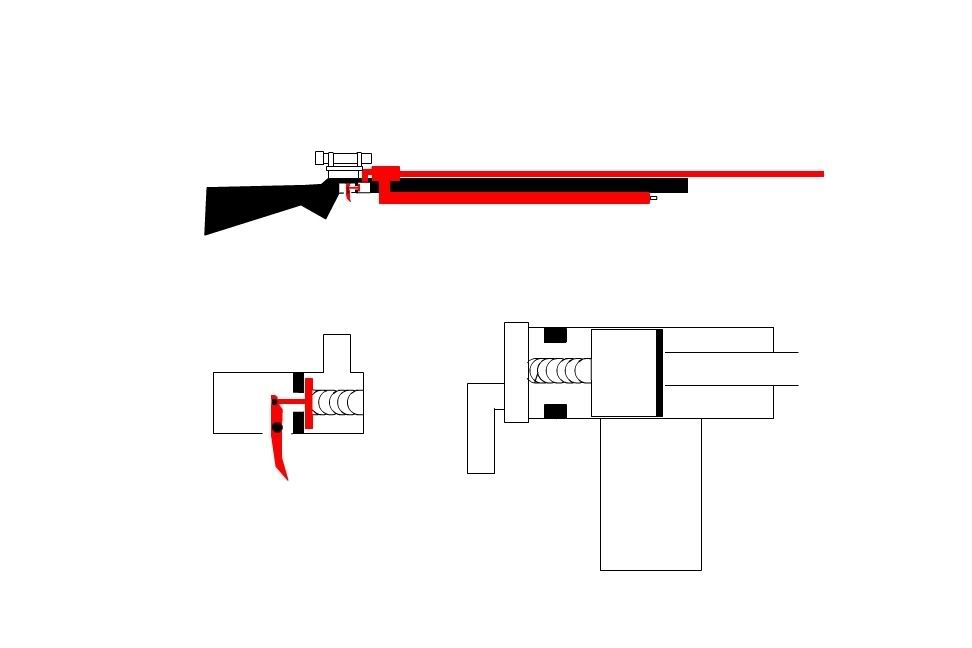

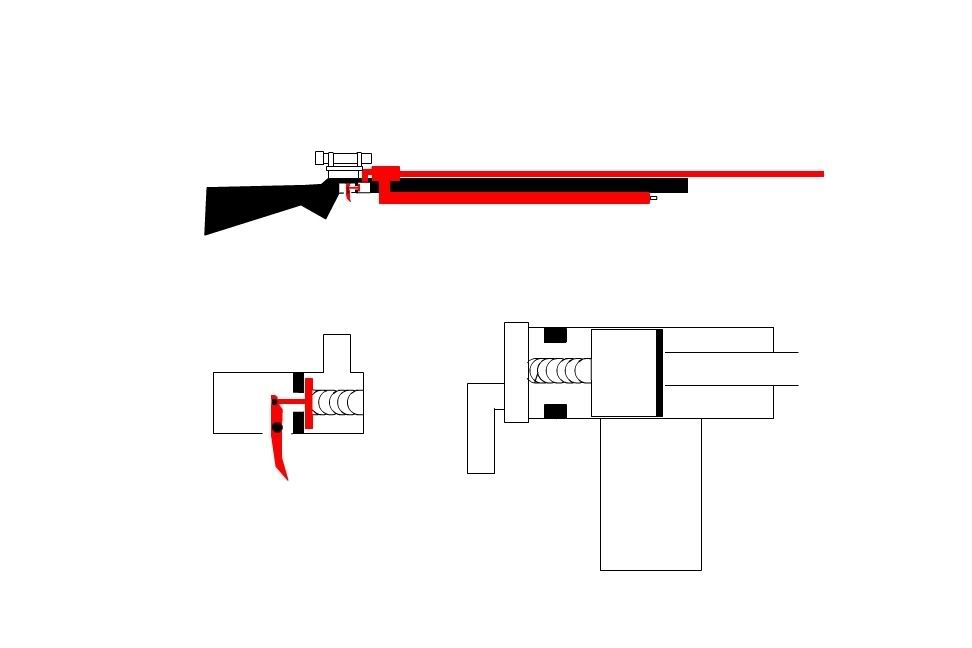

I'm planning on making a copper piston valved 8mm rifle. I was inspired by BTB to make the stock out of wood. I was inspired by Mitch's copper bb gun to make it a small bore and out of copper. I have made a plan and just want everyones thoughts/criticisms/comments/ideas and stuff on making it better. I plan on realism and power.

Here are the design pictures

Notice the custom blowgun design....

But i do have a few questions because i have never worked with copper before.

1. What is the best 8mm barrel i could use?

2. What is the best way to secure it into the piston valve? (If i cant solder it)

3. Any ideas on a breech loader? I was gonna use the standard sleeve pipe over and use o-rings but it might not be the best idea for such a small bore cannon.

Thanks

Marco

Posted: Sat Oct 13, 2007 2:14 am

by Mr.Russ

1. are you asking what would be the best option? or best thing to use for a barrel. you can probabyl get 8mm copper at bunnings, ive seen very small diameter copper there. if nor you can definately get 8mm aluminium there.

2. i would think maybe a compression fitting to do that. not sure though

3. do you want a sliding breech? it not there are many different ways. is your primary ammo going to be round? if so you could use a small T with a plug on top. take plug off put ammo in then put plug on. or you could use the ball valve idea, drill a hole in the side(if you can find one that small) and there are many other ways.

sorry if i didnt help lol.

Posted: Sat Oct 13, 2007 2:33 am

by Marco321

Mr.Russ wrote:1. are you asking what would be the best option? or best thing to use for a barrel. you can probabyl get 8mm copper at bunnings, ive seen very small diameter copper there. if nor you can definately get 8mm aluminium there.

2. i would think maybe a compression fitting to do that. not sure though

3. do you want a sliding breech? it not there are many different ways. is your primary ammo going to be round? if so you could use a small T with a plug on top. take plug off put ammo in then put plug on. or you could use the ball valve idea, drill a hole in the side(if you can find one that small) and there are many other ways.

sorry if i didnt help lol.

1. Yeah, what i mean is can i get 8mmID copper or will i need something different.

2. I'm not sure if a compression fitting will work because the copper has to go back into the tee to reach the piston.

3. The tee idea will work. I'm just looking for different ideas.

Thanks, ill have to have a look at bunnings.

Posted: Sat Oct 13, 2007 2:57 am

by Mr.Russ

im pretty sure you can get 8 mm id copper, but it might be 10mm smallest.

cant you push the pipe through compression fitting and then do it or not. (not very good with copper stuff)

and yeah thats all i got.

Posted: Sat Oct 13, 2007 3:18 am

by Marco321

Mr.Russ wrote:im pretty sure you can get 8 mm id copper, but it might be 10mm smallest.

cant you push the pipe through compression fitting and then do it or not. (not very good with copper stuff)

and yeah thats all i got.

Oh ok thanks

I'm not sure if i can use a compression fitting, as i said before, i have never used copper before.

Posted: Sat Oct 13, 2007 3:22 am

by spanerman

i wouldent use compression fittings..they compres the pipe(duh) and sometimes deform it...this may be bad for trying to get a piston in/out

Posted: Sat Oct 13, 2007 3:24 am

by Marco321

spanerman wrote:i wouldent use compression fittings..they compres the pipe(duh) and sometimes deform it...this may be bad for trying to get a piston in/out

Oh right thanks. Could i just put a threaded male plug, drill a hole in the plug then use kneed it epoxy to hold the barrel in?

Posted: Sat Oct 13, 2007 3:26 am

by spanerman

as long as it holds the barrel in the correct place and seals...i dont see why not

Posted: Sat Oct 13, 2007 4:01 am

by Marco321

spanerman wrote:as long as it holds the barrel in the correct place and seals...i dont see why not

Thanks. Will it hold the force a piston will exert on it at 300psi?

Posted: Sat Oct 13, 2007 4:09 am

by Brian the brain

All made out of copper it will hold 300 psi.

8 mm is very small, so it won't take too much stress.

Posted: Sat Oct 13, 2007 4:22 am

by Marco321

Brian the brain wrote:All made out of copper it will hold 300 psi.

8 mm is very small, so it won't take too much stress.

Thanks

One more question. I see there are various grades of copper. Which one will be best to use?

Posted: Sat Oct 13, 2007 5:27 pm

by DYI

Type K has the highest pressure rating, but is difficult to find.

Type M has a lower pressure rating, but is easy to find.

Type L is somewhere in between in terms of pressure rating but, strangely, is often more expensive than Type K.

DWV copper is usually only available in larger sizes, but is still usually rated for more than 300 psi, however the DWV fittings are often only rated around 200-250.

They should all be fine for an 8mm 300 psi design.

Posted: Sat Oct 13, 2007 7:17 pm

by Marco321

DYI wrote:Type K has the highest pressure rating, but is difficult to find.

Type M has a lower pressure rating, but is easy to find.

Type L is somewhere in between in terms of pressure rating but, strangely, is often more expensive than Type K.

DWV copper is usually only available in larger sizes, but is still usually rated for more than 300 psi, however the DWV fittings are often only rated around 200-250.

They should all be fine for an 8mm 300 psi design.

Thanks mate, i appreciate it.