Page 1 of 1

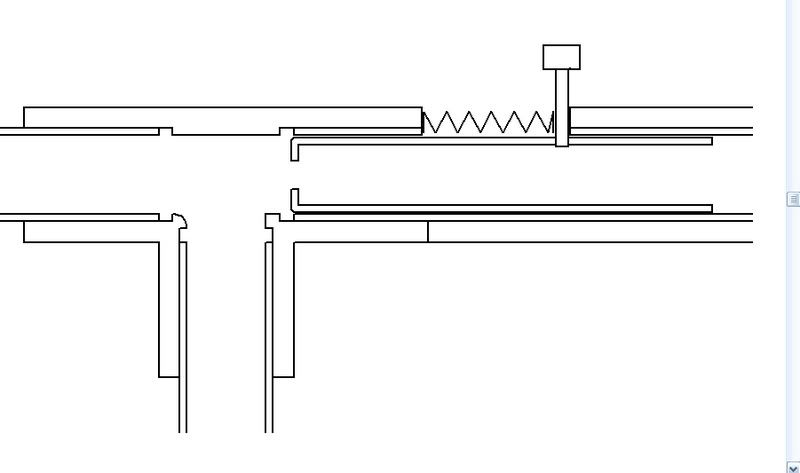

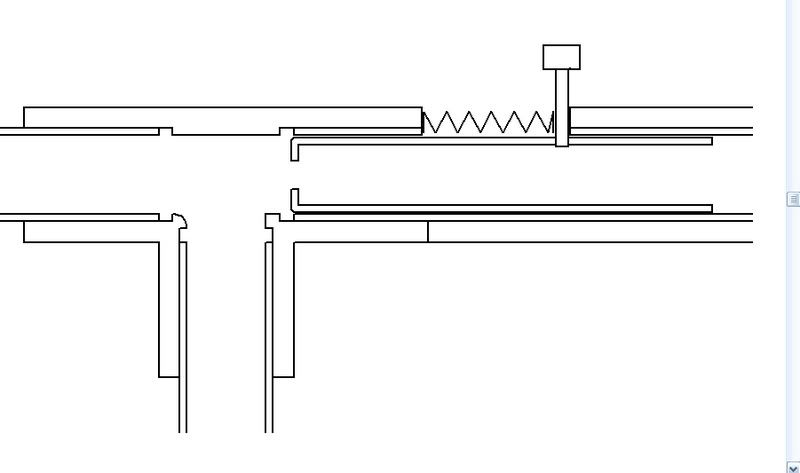

simple semi auto bolt

Posted: Tue Nov 27, 2007 12:21 am

by homedepotpro

Posted: Tue Nov 27, 2007 12:28 am

by jackssmirkingrevenge

Nice. it's a variation of the blow forward bolt that works, but perhaps not as well in terms of performance and efficiency because of the flow restriction.

Posted: Tue Nov 27, 2007 3:39 pm

by SpudUke5

Im sorry but im not sure if i understand it. The forward action of the bolt pushes the projectile out right? If so, then i understand.

Posted: Tue Nov 27, 2007 4:05 pm

by jackssmirkingrevenge

The pressure coming into the breech is entering faster than it can escape though the small hole in the bolt, so the pressure difference means the bolt is pushed forward, sealing the barrel and closing off the magazine. The projectile is then propelled out by the air leaking through the hole in the bolt.

Posted: Tue Nov 27, 2007 5:54 pm

by potatoflinger

That's awesome! It may be better suited for airsoft pellets or bb's, but it is still an amazing job. I can't wait to see it in a completed cannon.

Posted: Tue Nov 27, 2007 6:20 pm

by BigGrib

i still dont understand why you would want to have a blow forward bolt i mean the reason machine guns use it is to help cool the barrel between shots as the air can flow through the barrel instead of just outside the barrel, with the restriction you have in the bolt what kind of fps are you getting out of your projectile, it just seems to be a waste of air to me, there should be a much more efficent way

Posted: Tue Nov 27, 2007 6:55 pm

by bob-a-lu

hey homedepotpro will you make a how to for that please or just pm me on how to do it be cause i want to use this with my new gun.plz?

Posted: Tue Nov 27, 2007 7:43 pm

by Hailfire753

Nice, simple design. I like the electrical-tape o-ring!

To me this seems more suited for people who don't have the knowledge or capability to make the original blow foward.

What I want to learn in how to make a bolt that is normally closed, but opens right before pressure is applied, and closes again on pressure. This is the kind found in most high-quality paintball guns, as far as I know.

For your bolt, to increase performance you should increase the restrictor hole size as much as possible while making sure it still works.

Posted: Tue Nov 27, 2007 7:51 pm

by Hubb

Hailfire753 wrote:...For your bolt, to increase performance you should increase the restrictor hole size as much as possible while making sure it still works.

Maybe doing away with restrictor hole completely and adding a homemade check valve to the front, making the tension on the check valve just enough so that it opens when the bolt is fully closed.

Posted: Tue Nov 27, 2007 8:00 pm

by Hawkeye

I would think it would be beneficial to work the optimum flow restriction into a homemade paintball repeater if it means conserving air and limiting velocity. The goal probably isn't to have insanely high velocity paintballs.

I am currently assembling a paintball repeater in which I am going to reduce the barrel diameter where the piston seals to conserve air. With this set-up I am hoping for a gun that shoots 5-10 good shots.

It will have my piston/hammer valve theory put to the test. A long chamber under the barrel will hold the shooting air and the stock will be a chamber for resetting the piston.

It will just have a manually operated bolt though. I don't like the idea of the ball sitting in an unsealed area when the air hits it. Quite a bit must go into the magazine before the bolt fully seals it.