Page 1 of 1

Airflow questions

Posted: Fri May 09, 2008 7:12 am

by M.J.P.

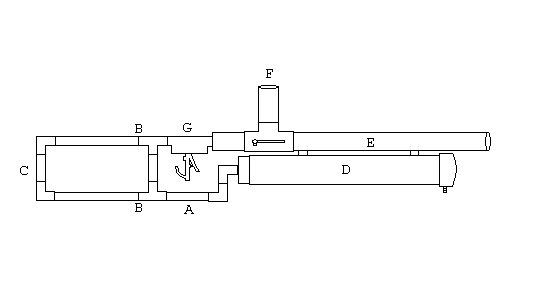

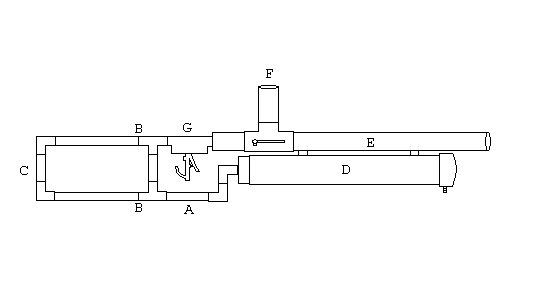

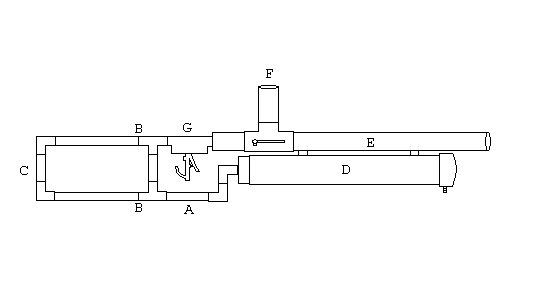

Okay i've slightly redesigned the gun, if you can see any problems with airflow and other technical stuff like that could you please comment. Thanks

(A) 1" pressure rated PVC fittings

(B) 3/4 " pressure rated endcaps fitted backwards into 1" tees.

(C) 3/4" pipe and fittings for the stock, connected to the 3/4" endcaps (B)

(D) 2" x 25" pressure rated SCH 80 PVC as chamber with bushing (left) and endcap (right). (Schrader valve tapped into endcap.)

(E) 1 1/2" SDR-21 PVC sleeved inside of 2" SCH 80 PVC

(F) Bolt action reloading mechanism

(G) 1" Modified sprinkler valve with a blowgun valve as pilot

Any problems? Leave a comment, cheers.

Posted: Fri May 09, 2008 7:15 am

by JDP12

why not scrap that drop down under sprinkler valve and run a straight 3" elbow to a bushing to the valve, then just attach the stock with hose clamps or something?

Would give a bit better flow

Posted: Fri May 09, 2008 7:17 am

by M.J.P.

Yer thats a good idea but then what do you suggest for a valve?

If still a sprinkler where should the trigger go?

Posted: Fri May 09, 2008 8:33 am

by Zippster

If done discretely and tastefully, it probably wouldn't hurt all that much to run a 6" hose from the sprinlker pilot to a blowgun mounted more ergonomically on a grip. As long as the flow restrictions arent too bad, it should work just as well.

Posted: Fri May 09, 2008 8:35 am

by koolaidman

Don't hoseclamp the stock. If you dont want the stock pressurized, glue in a 3/4 endcap into the 1" tee, they fit nicely, and have the stock be 3/4." I think the idea came from the 25mm sniper.

Posted: Fri May 09, 2008 8:42 am

by bigbob12345

the twists and turns will deacrese the velocity by maybe a few fps so it doesnt matter, but your chamber is way overkill and with a chamber that size, the sprinkler is constricting flow like mad.

What I reccomend you do is keep the chamber size and then make a 2in piston valve with a 1.5in porting, it isnt that hard to make just takes some fiddling around with.

And if you dont know what a piston valve is then search.

Posted: Fri May 09, 2008 5:44 pm

by M.J.P.

koolaidman wrote:Don't hoseclamp the stock. If you dont want the stock pressurized, glue in a 3/4 endcap into the 1" tee, they fit nicely, and have the stock be 3/4." I think the idea came from the 25mm sniper.

Yes i might try that except does it hold pressure well? I guess if it was a perfect fit it would be fine. Do you think their would be a problem with a pressurized stock?

bigbob12345 wrote:... but your chamber is way overkill and with a chamber that size, the sprinkler is constricting flow like mad.

What I reccomend you do is keep the chamber size and then make a 2in piston valve with a 1.5in porting, it isnt that hard to make just takes some fiddling around with.

Yeah i know what a piston valve is and i will consider a barrel sealing tee valve, but if i never get round to that and still use my 1" sprinkler what size chamber do you recommend?

Posted: Fri May 09, 2008 6:01 pm

by BigGrib

Typically you don't want the valve smaller than the barrel really, which is why a lot of guys go for making their own piston valves. For my Pneumatic GB Cannon I have a 1.5" Irritol sprinkler valve and a 3" x 18" chamber. The Blowgun trigger can be attached by a small hose and clamped somewhere more ergonomically fitting, but as JSR will tell you, the smaller the pilot volume the better off you are.

Posted: Fri May 09, 2008 6:01 pm

by bigbob12345

M.J.P Well a 2in by 24in chamber should get decent velocity but if you want a little more power then a 2in by 30-36in chamber will work good.

Or to get a similar volume but less length you can go with a 16-18in long 3in chamber.

Posted: Fri May 09, 2008 6:04 pm

by Pilgrimman

I use about 2' of 2" pipe for barrels like that. Your chamber is overkill. As for flow restrictions, the valve is the biggest choke point, but you probably aren't looking to break the sound barrier or anything

Just make the chamber smaller, and your cannon is good to go!