Page 1 of 2

Semi-auto piston under constant air flow.

Posted: Sat Aug 09, 2008 7:45 pm

by Leonard

Hey guys! Just a quick question for you and hopefully some inspiration if there is anything new in what i am presenting.

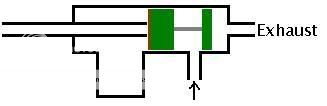

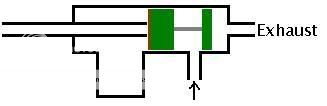

The air input in this design is the vertical tube at the bottom, where there is an arrow pointing into it. By leaving constant air flow through the input, can i achieve a semi-auto piston by opening the exhaust with a solenoid valve for a second and then closing it?

I fear that the piston might not actuate if my pilot as less flow than my barrel. What do you guys think? This is a for piston semi-auto design, loosely based on a spool valve design (obviously the bolt part in not drawn, i'll keep it for later

)

Posted: Sat Aug 09, 2008 11:26 pm

by clide

It would probably work, but it would be easier and most likely more efficient to just hook up a 3-way valve for the exhaust.

Posted: Sat Aug 09, 2008 11:50 pm

by noob of noobs

@ Leonard: I think that looks like a great idea. If you can get a good seal between the exhaust vavle and the input valve with that piston, I think it'll work. The extra pressure from the air source might actually help push the piston forward if it can't get behind it.

EDIT: With the three way valve, how would you use it? You'd have to turn it one way to put gas in, and turn it another to get gas out right? So your entire trigger action would involve 2 turns, right?

I think a better investment would be to simply use 2 valves. For my design, I'm considering using a blowgun to allow propane into the gun triggered by my left hand and a blowgun used to trigger the gun in my right hand. It'd still be 2 actions, but seems a bit easier to use than turning the same valve twice.

Or you could just use the design you already have planned out and hope it works.

Posted: Sun Aug 10, 2008 11:53 am

by clide

noob of noobs wrote:

EDIT: With the three way valve, how would you use it? You'd have to turn it one way to put gas in, and turn it another to get gas out right? So your entire trigger action would involve 2 turns, right?

I think a better investment would be to simply use 2 valves. For my design, I'm considering using a blowgun to allow propane into the gun triggered by my left hand and a blowgun used to trigger the gun in my right hand. It'd still be 2 actions, but seems a bit easier to use than turning the same valve twice.

Spring load the 3-way valve so you only have to pull it in one direction, then you just release to recharge the gun.

http://www.spudfiles.com/forums/semi-auto-t160.html

Or you could use an electronic 3-way with a momentary switch for even faster actuation.

Posted: Sun Aug 10, 2008 4:07 pm

by Leonard

Thanks for the help guys. I could surely use a three way solenoid, if i wanted to build a gun that would cost over 200 bucks to make. Im basicly working on the most efficient semi-auto design V.S. lowest cost and number of tools required.

Posted: Sun Aug 10, 2008 4:38 pm

by clide

Ebay is a pretty good source for cheap valves. Although they sometimes take a bit of searching to find the right keywords.

One of the downsides to this design is that you need to rely on an restrictive equalization hole (or piston blow-by) for filling. With a 3-way valve you can put a check-valve in the piston to create fast fill times, however with this design increasing flow to the chamber side may cause some valve seating problems and probably a further loss of efficiency.

Posted: Sun Aug 10, 2008 4:53 pm

by Leonard

The barrel will be 6mm, so you can guess that the chamber will be very small. I will be using high pressures (possibly up to 500psi), so volume of air will not be all that important.

Posted: Sun Aug 10, 2008 10:27 pm

by jackssmirkingrevenge

You don't really need the complication of a spool valve, have a look at what I had done

here:

The chamber is refilled through a restricted opening from the firing side while the pilot is filled by air blowing by the piston, held shut by a spring in the meantime.

Three-way valves are a good idea, you might want to look at

how pneumatic nailguns work for some inspiration. You can also pick up such devices quite cheaply off auction sites and with a bit of ingenuity and lots of epoxy, they can be readily converted for this purpose

I would also suggest reading through

this thread which includes a discussion on a similar system, incorporating a piston driven bolt reloading mechanism - though as far as I know no actual prototypes were built.

Posted: Sun Aug 10, 2008 11:08 pm

by Leonard

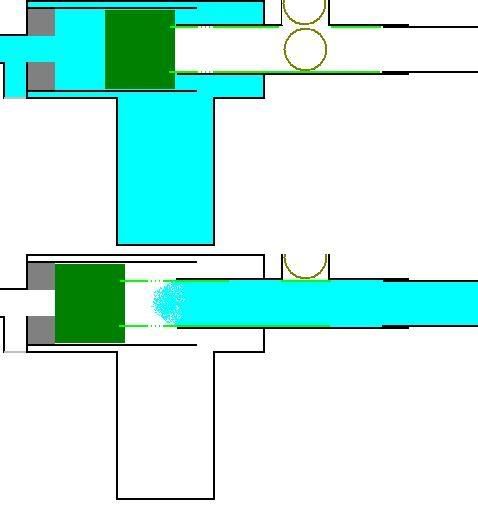

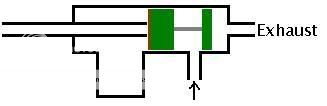

I get where you're coming from. But, considering what are my goals, i'd like you to take a look at the full design, including the bolt :

This can be completed with four part :

- 1/2" copper pipe

- 9/32 brass pipe (barrel)

- 10/32 brass pipe (perfect fit around barrel)

- Epoxy

I've already made a working prototype of the piston/bolt that worked with two blow gun. One to fill and one to pilot. Slow firing since i had to depress the fill blow gun and press the pilot, but it worked pretty well! Here it is :

So basicly im just looking into upgrading the working version i have with the pilot method i am describing in this thread. I managed to make the first prototype for under 20 dollars (excluding c02 fill system, obviously) and i had satisfing performance.

I can understand that this design would be hard to get to work properly, but i just dont wanna copy your ideas as i have done in the past. I came up with something relatively new with the prototype i just posted, i'd like to get it to work even better (full auto with a pop-up as pilot and blowgun as fill). Sharing the results with the spudfiles will be more satisfing if i build something new ^_^

Thanks for your help, trow in some feed-back on the pilot im presenting.

Posted: Mon Aug 11, 2008 7:56 am

by jackssmirkingrevenge

I understand the need to innovate, though If I could make one suggestion, a smaller secondary piston as shown in the attached diagram would make it much easier to re-seal the piston.

Alternatively, you might want to consider making your own three-way-valve-on-a-budget using an ordinary ball valve and a drill

Posted: Mon Aug 11, 2008 10:02 am

by al-xg

Oh, just saw a similar design on the french forum, either coincidence or someone got inspired

http://patator.frbb.net/depannage-f10/q ... -t3097.htm

http://patator.frbb.net/depannage-f10/q ... -t3097.htm

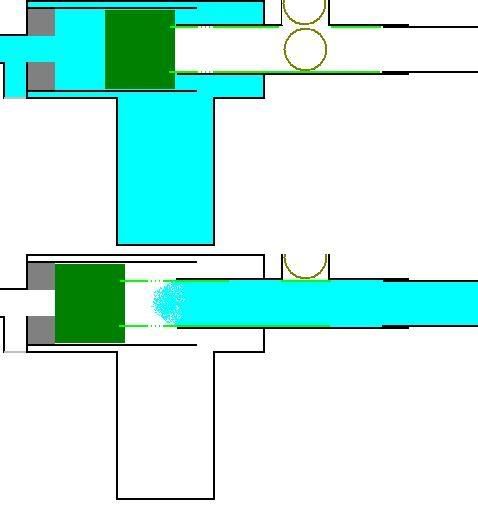

And my drawing of a possible set up, using brass fittings (not very easy to get pressure PVC in France).

A washer and a spring would go between the pilot valve and the piston, to push it forward.

With this set up the main chamber or filling port, is on T no1, so the only action needed to fire is the opening and closing of the pilot valve.

Reloading of the ammo could be achieved in many ways.

Posted: Mon Aug 11, 2008 10:33 am

by jackssmirkingrevenge

Love the hand-drawn exploded view, class

Posted: Mon Aug 11, 2008 10:41 am

by al-xg

Hand drawn into MS Paint

Oh and I just read the topic title ( I just saw the pictures the firt time

), and there are actualy working constant flow semi-auto piston canons on the french site too.

At normal spudgun pressures they don't waste too much air, and are really quite simple to design and make.

Posted: Mon Aug 11, 2008 10:47 am

by trollhameran

My pump action prototype is just a normal piston gun, but if i leave the compressor on, it works semi auto, you just have to open and close the ball valve quickly so you don't waste to much air. I was thinking though, if you grind of the stops on the ball valve handle and bolt another handle perpendicular to that, you could turn the handle right around like a crank, which would give you two shot for each full turn of the handle.

http://www.spudfiles.com/forums/pump-ac ... 15576.html

Posted: Mon Aug 11, 2008 12:04 pm

by Leonard

Al-xg, on se voit bientôt sur le forum français! Merci de ta participation dans ce sujet. As-tu déjà construit le prototype illustré dans ton dessin?

Thanks everybody, i'll get to the building right away, you'll hear from me in a week or two with a (hopefully) working prototype.

)

)