Page 1 of 3

Slide Check Modification

Posted: Thu Aug 14, 2008 4:14 pm

by PVC Arsenal 17

I recently bought a slide check valve to use on a golfball mortar I will be building (slide check will be spring loaded and have a paddle attached so that when a ball falls down the barrel, it his the paddle, opens the valve, fires, resets, etc.)

Problem: When I was testing the slide check on a 3/4" QEV today, it seemed like it wasn't quite enough to pilot the QEV. I've seen these used with 3/4" QEVs before on an airsoft website, so there some way to make it work. It could just be that the type of slide check I have is different (small vent hole), or maybe they drilled out their vent holes. I think I will end up drilling the hole out. The blue piece is easily removable, exposing the hole. But how can I drill it and make it smooth enough so that the hole isn't jagged? (Which would cause the o-rings to get ruined)

Here is a picture of my valve showing the vent hole:

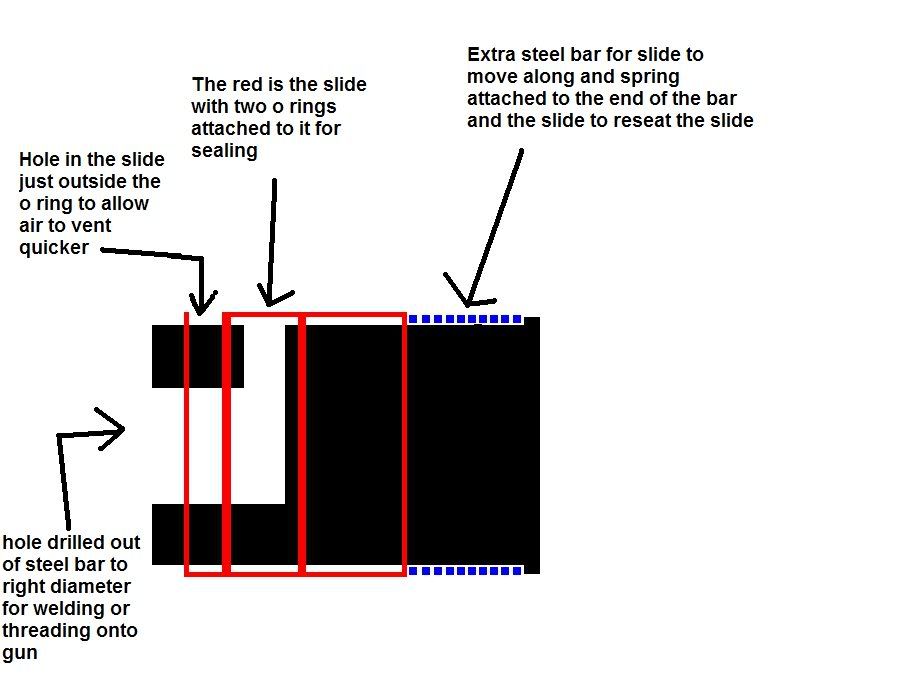

Here is a diagram of how a slide check valve works in case anyone doesn't know:

And

here is an example of one working with a 3/4" QEV. This thing is awesome.

I see you Crowley!

Posted: Thu Aug 14, 2008 4:56 pm

by psycix

I guess you should make the vent hole larger, but an even better idea is, to simply make more of them.

Make multiple vent holes all around, but make sure they are on the same line (or in this case: circle)

For not ruining the o-rings I guess you could use a larger drill bit to make the ends of the hole tapered.

A bit like this:

\ /

||

( but then something like 45 degrees or less, and not that deep)

There is a small error in the diagram:

The bottom volume between the slider and the pipe, is never blue, but actually, this is the same volume as the top volume of it. So that should be blue too.

Posted: Thu Aug 14, 2008 5:10 pm

by PVC Arsenal 17

You're right about that error. But I didn't make the diagram!

Tapering the hole should work. I want to try just enlarging the existing hole before attempting to make new ones. I've had bad experiences attempting to drill cylindrical objects (bit slips, scratches surface)

Posted: Sat Aug 16, 2008 5:51 am

by psycix

Well, I assume that if you lock your workpiece down in a drill press, your bit wont slip (make sure to drill in on perpendicular angle).

I am somewhat afraid that your O-ring will mess up faster when you enlarge the hole instead of making additional (tapered) ones.

You will want optimal performance, and thus as many holes as you can. The holes should be capable of just as much flow as the flow can go through the previously discussed volume to have optimal performance. You can replace the word "flow" for "total surface area" here.

Posted: Sat Aug 16, 2008 9:58 am

by Gippeto

Do you have a vice for your drill press?

Place the cylinder in the vise horizontally. Use a center drill to start the job.

Then place a small ruler on the cylinder. Hold it in place (lightly) with the center drill.

When the center drill is directly over the center of the cylinder, the ruler will be parallel with the drill press table.

Clamp things down and re-check for alignment.

Drill a "dimple" into the cylinder. Now without changing alignment, change the drill bit to the one you require.

It will start in the dimple, and will not skid off.

Using cutting fluid, a sharp bit and a slow feed speed will result in the smallest burrs on the inside of your cylinder.

Use WD-40 for aluminum.

Best of luck.

Posted: Sat Aug 16, 2008 12:05 pm

by daberno123

Or if you don't feel comfortable modifying the slide check valve, another (smaller) QEV could be used to pilot the 3/4" QEV, then the slide check valve piloting that one.

I really like the idea of using one of these, and I was wondering if the threads on each side are NPT, or were they paintball ones that you had to get an adapter for?

Posted: Sat Aug 16, 2008 1:16 pm

by PVC Arsenal 17

I do have a drill press, Gippeto. I'll give that a try thanks.

The inlet is 1/8" NPT female. Outlet is 1/8" NPT male.

I got mine

here. The best price I've found so far. And the milling on the slide part is convenient for attaching some sort of trigger.

Posted: Sat Aug 16, 2008 1:35 pm

by trollhameran

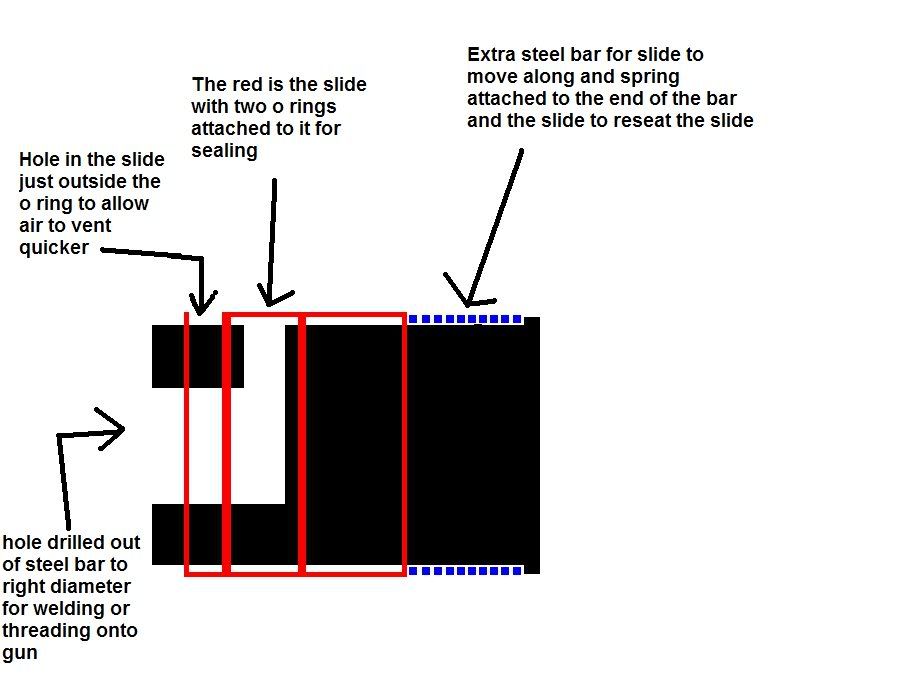

How hard do think it would be to make one yourself, that way you could make the vent the size you want to begin with, and also you would only need one vent rather than two, if your using it for a pilot.

Posted: Sat Aug 16, 2008 1:50 pm

by Gippeto

@ trollhameran

That crossed my mind as well.

I wonder if it would be better to have a series of smaller vent holes around the diameter.

I know area increases by a factor of 4 when you double the diameter.

But you would have to move the slide twice as far to achieve that flow.(slower opening time)

Smaller holes would result in the slide only having to move a small amount to get full flow. (faster opening time)

Or two rows of smaller holes for really improved flow.

I wonder how badly air friction would affect the flow rate if smaller holes were used?

Posted: Sat Aug 16, 2008 2:00 pm

by al-xg

Oh, I've had to do this already ona 1/8" slide check.

I wouldn't make the hole bigger but I would drill a few more of the same size.

The reason is that the O-ring can get sucked in localy, and then get scissored when the valve is closed again.

Mind you I was using 850psi, the risk is much smaller at lower pressures.

And remeber to smooth the edges of the holes off, wich if sharp can also damage the O-ring.

Posted: Sat Aug 16, 2008 2:26 pm

by Hailfire753

Where did you find that slide valve? I can't find them in stores.

I say drill ,ore small holes; opening time is more important.

Al-xg, were you using it with co2?

Posted: Sat Aug 16, 2008 2:37 pm

by al-xg

3000psi HPA paintball bottles regulated down to 850psi.

I also have made a High pressure pump, wich is meant to achieve at least 850psi, but haven't found the motivation to finish it yet.

I actually also got that small slide check from a paintball remote line.

Posted: Sat Aug 16, 2008 3:26 pm

by PVC Arsenal 17

I drilled 3 additional holes around the diameter. It now works great. However, I damaged one the o-rings somehow. I think the lubrication I used ate them up or I cut it on the male threads taking the slide off.

Posted: Sat Aug 16, 2008 4:11 pm

by PVC Arsenal 17

(the sound is actually much louder)

Posted: Sat Aug 16, 2008 4:18 pm

by daberno123

Looks good, do you plan on adding some sort of trigger, instead of pulling it back each time?

Looks pretty easy to pull back, how much pressure are you using?