Page 1 of 1

quick question

Posted: Sun Apr 19, 2009 6:37 pm

by colty-bear

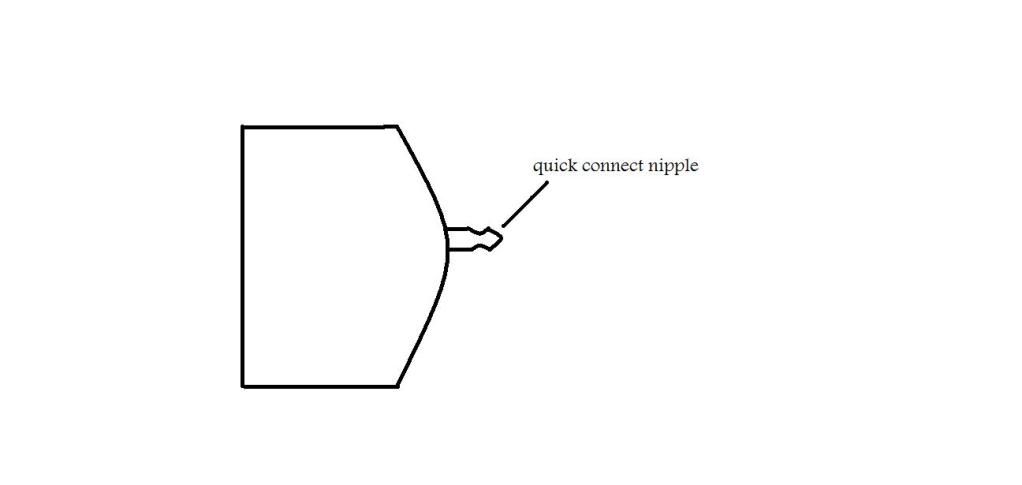

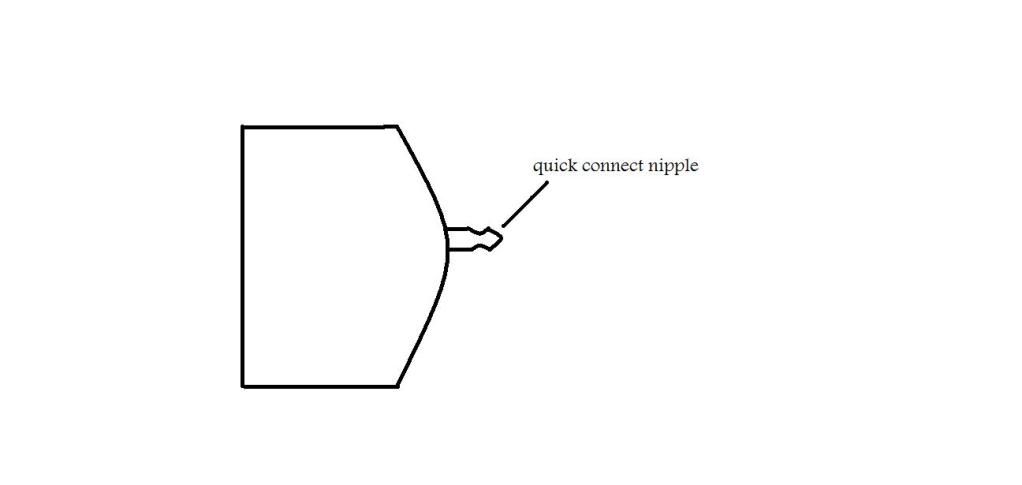

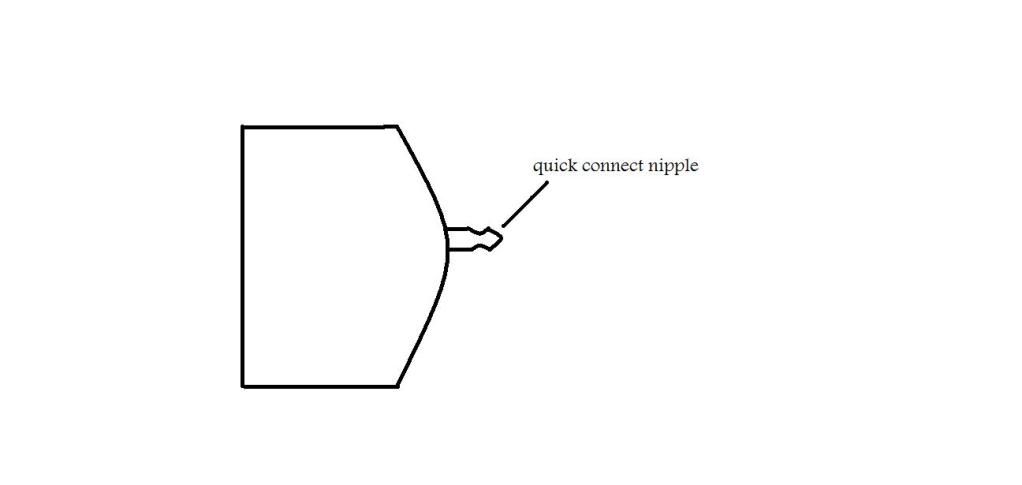

how do you hook a quick connect nipple to a 3 in end cap like this

this is what nipple looks like

it has to hold 150 psi without leaking and so it will hook up directly to the cap for constant air flow

Posted: Sun Apr 19, 2009 6:43 pm

by jmeyer1022

Drill a hole, Get a 1/4 tap and do the hole. Teflon tape the threads then screw it in. Epoxy around the seem for a better seal.

Posted: Sun Apr 19, 2009 6:47 pm

by colty-bear

thanx i really needed to know for my semi

Posted: Sun Apr 19, 2009 6:47 pm

by c11man

first of all, drilling holes into a endcap is a bad idea especaly at 150psi and 3inch fittings

so instead of hooking it up to the endcap attatch it to where the cap glues onto the pipe and it is 2 layers thick.

secondly we need to know what size threads are on the quick connect.

normaly they are 1/4inch so if it is metal (not plastic like in the pic) you just need to drill a 7/16 and thread the quick connect into it.

if it is plastic then you will need a 1/4inch tap or a metal fitting that is 1/4inch threads.

good luck!

c11man

EDIT: wow i type slow...

Posted: Sun Apr 19, 2009 6:48 pm

by SubsonicSpud

Make sure you place it through a double section in the end cap after the cap is in the pipe. If you want to be able to remove it, drill out a hole that tightly fits the thread of the fitting, then use a half nut that fits the thread on the inside. You may or may not have enought thread protruding to do that.

If you want a more permanent fixing, skip using the nut and use epoxy glue around the thread, slide the fitting in and place more epoxy around the thread protruding inside, then let it cure for 24hours

SubsonicSpud