Page 1 of 1

Pneumatic Plans

Posted: Wed May 27, 2009 12:15 pm

by mikemurph

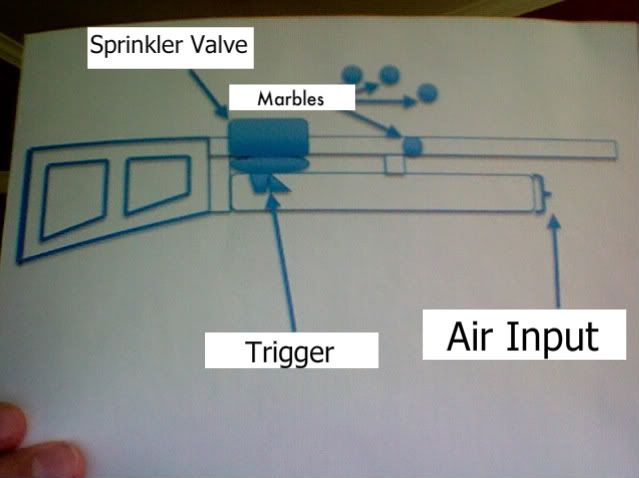

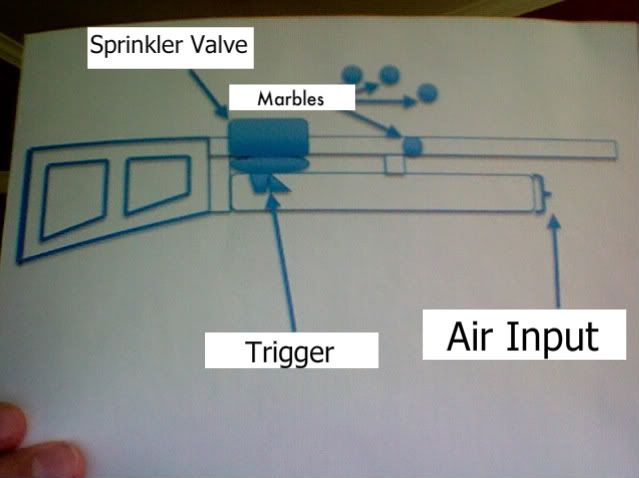

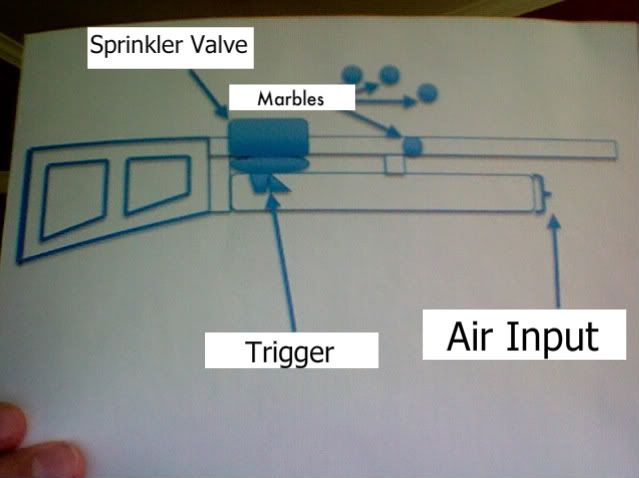

I'm crossing over to the pneumatic side, I've got my sprinkler valve modified and my plans are all drawn up, tell me what you think about this gun

Its a pretty simple design, but I think it should work pretty well. Tell me what you think

Posted: Wed May 27, 2009 12:19 pm

by spudtyrrant

did you plan on making the stock out of wood or pvc if you use pvc be sure to seal it off from the main chamber so you have better flow but besides that everything looks ship-shape

Posted: Wed May 27, 2009 12:23 pm

by mikemurph

PVC stock, and by the way, do the have connectors that can joint pipes at weird angles not just 90? I want the stock to be detachable.

Posted: Wed May 27, 2009 12:28 pm

by spudtyrrant

mikemurph wrote:PVC stock, and by the way, do the have connectors that can joint pipes at weird angles not just 90? I want the stock to be detachable.

they have 90's and 45's for just bends if you want an angle other that that since its not going to be hold pressure you could dip them in boiling water for 30 seconds and carefully bend them to the angle you want

Posted: Wed May 27, 2009 5:36 pm

by Technician1002

spudtyrrant wrote:mikemurph wrote:PVC stock, and by the way, do the have connectors that can joint pipes at weird angles not just 90? I want the stock to be detachable.

they have 90's and 45's for just bends if you want an angle other that that since its not going to be hold pressure you could dip them in boiling water for 30 seconds and carefully bend them to the angle you want

Boiling water is not hot enough for most PVC bending. You need to heat PVC to the point it becomes like a garden hose. It must be heated evenly as it is very easy to scorch (brown) or burn. For Christmas decorations I make PVC candy canes. Straight PVC pipe is taped and painted to provide a candy cane stripe. The ends are plugged and pressure of about 10 PSI is applied to prevent flattening in the bend. It is gently heated above a camp stove (moving rapidly and rotated to heat a long section) and then wrapped onto a small bicycle rim and cooled.

EDIT I forgot to mention that surgical tubing with a knot in one end is perfect for this. Slide in, inflate, bend, deflate, and remove. No flattened bends.

I don't have pics of my process, but using a kitchen oven, the process is documented here, except they paint or tape after bending.

http://computerchristmas.com/christmas/ ... LowLimit-5

Posted: Wed May 27, 2009 6:37 pm

by Moonbogg

Your other cannons were pneumatic as well weren't they?

Posted: Wed May 27, 2009 8:01 pm

by MountainousDew

Moonbogg wrote:Your other cannons were pneumatic as well weren't they?

Nah, this was the guy who made all those mini-combustions...

Posted: Wed May 27, 2009 8:48 pm

by Moonbogg

MountainousDew wrote:Moonbogg wrote:Your other cannons were pneumatic as well weren't they?

Nah, this was the guy who made all those mini-combustions...

Ooooohh. OK got it.

Posted: Thu May 28, 2009 9:47 am

by spudtyrrant

Technician1002 wrote:Boiling water is not hot enough for most PVC bending. You need to heat PVC to the point it becomes like a garden hose. ]

boiling water seems to work for me i use it to flatten pvc into sheets and flare pipe all the time. your method works too. boiling water just the way I've always done it