I don't have too much time to ponder it.

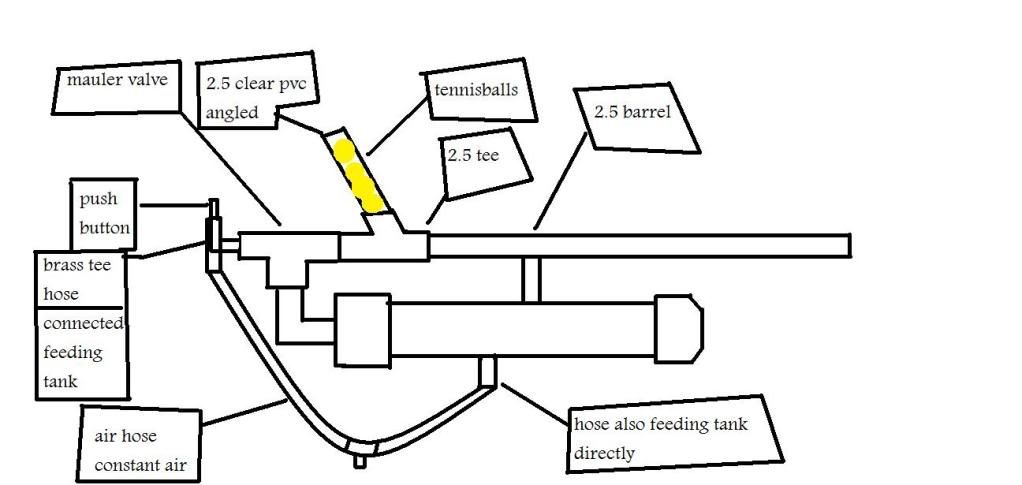

Seems like the "T" should be turned 90 with the fill going into side and the "push button" on the back.

That way it would fill behind the piston.

Might need to restrict the flow some "T" on the fill side.

(if that will even work(?)).

If it did work You could also use a "T" rather than the 90 connecting the chamber,

A plug (edit: w/hole drilled in it) would go in the "T", A piston and spring could press a small rod (edit: to outside of chamber) back so when the proper chamber pressure is reached it automatically depresses the pilot valve.

For semi-auto the rod would be locked in the forward position...No more time now

Just some thoughts. Oh, real quick...a Blow- forward bolt maybe made from epoxy would be best for similar design IMO... Check back Later 8)