Page 1 of 2

my second shock pump (full diatelas)

Posted: Tue Jul 07, 2009 6:06 pm

by far_cry

i finished building my new hand pump .and she work nice

the highest pressure i get from this pump is 700 psi

the cylinder is 2.7mm in diameter

the shaft rod is 8mm

any questions ? fell free to ask

and here the pictures of the lady shocky

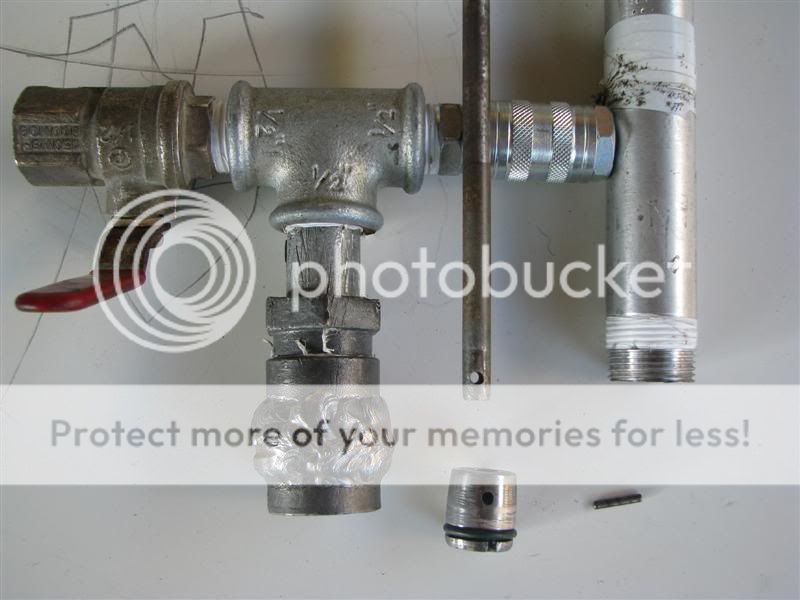

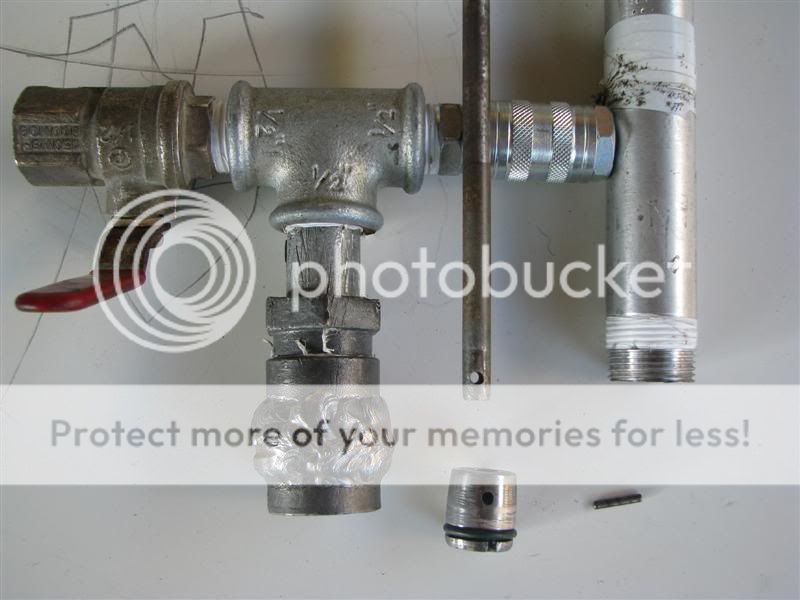

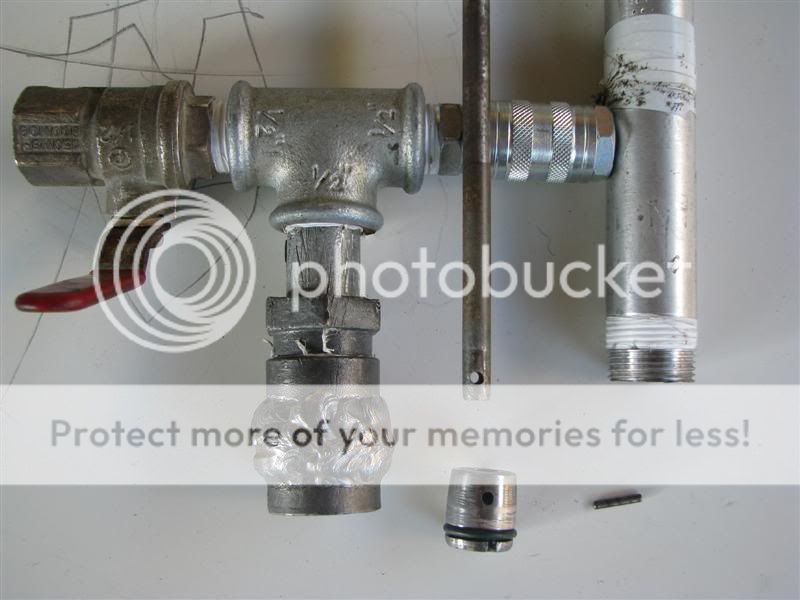

the chick valve parts

the piston

the piston

the cylinder+shaft+chick valve

the cylinder+shaft+chick valve

the pump stand waiting for work

the pump stand waiting for work

Posted: Tue Jul 07, 2009 6:13 pm

by THUNDERLORD

"She" looks soo sexy,

Hope she don't shoot another hole in you hand.

Wish there were some more diagrams...700psi(really???), Awesome pump there!!! 8)

Thanks

Posted: Tue Jul 07, 2009 7:23 pm

by Gippeto

Nicely done Far Cry. 8)

Nice sturdy handle on it too.

Posted: Tue Jul 07, 2009 8:05 pm

by jonnyboy

Nice build, I thought about building a shock pump but I really don't have the need for one.

I do have a high pressure project in the works but co2 sounds better anyway.

On your chick valve what 2 pieces did you weld together?

BTW nice welding job

Posted: Tue Jul 07, 2009 9:19 pm

by twizi

jonnyboy wrote: I thought about building a shock pump but I really don't have the need for one.:

if u build one im sure youll find somthin to do with it

btw whats the cylinder

Posted: Wed Jul 08, 2009 12:16 am

by THUNDERLORD

Forgot to mention, You could always get a good injury attorney and sue the company that made the other pump that broke (and injured your hand).

Maybe you're still having nightmares about the whole incident...

Even became obsessed to build a metal pump(???)...

8)

Posted: Wed Jul 08, 2009 12:32 am

by Technician1002

THUNDERLORD wrote:Forgot to mention, You could always get a good injury attorney and sue the company that made the other pump that broke (and injured your hand).

Maybe you're still having nightmares about the whole incident...

Even became obsessed to build a metal pump(???)...

8)

Abuse of the product on the part of the end user might be proved and not be a manufacturing defect. May need to read the owners manual. Proper hand placement and pressure may have avoided this accident. This would not be an open and shut case against a company for a defective product.

But then again, getting hot coffee and it actually being hot.. May have a chance.

These lawsuits are why manufacturing is leaving the USA. The Flu vaccine is produced overseas simply due to the high cost and risk of lawsuits. It is why I don't manufacture and sell t shirt launchers.

Posted: Wed Jul 08, 2009 12:39 am

by THUNDERLORD

Technician1002 wrote:.. May have a chance...

So what's your point then???

Posted: Wed Jul 08, 2009 2:58 am

by inonickname

Yep- America is extremely sue happy.

As technician said, people suing McDonald's for her coffee being too hot- they now have to serve it under a certain temperature.

And the woman who was driving her Winnebago, got up, made a coffee and crashed. She sued Winnebago (and won) because the ad said she could do that..

On topic: Very nice pump! How do you get such high pressure with that sized cylinder?

Very noice!

Posted: Wed Jul 08, 2009 5:09 am

by far_cry

Gippeto wrote:Nicely done Far Cry. 8)

Nice sturdy handle on it too.

thank you. this handle will not break into my hand

jonnyboy wrote:Nice build, I thought about building a shock pump but I really don't have the need for one.

I do have a high pressure project in the works but co2 sounds better anyway.

On your chick valve what 2 pieces did you weld together?

BTW nice welding job

thank you.i have been welding a lot in my life.and the chick valve is galvanized 3\4" nipple with inner threads (i did not know what they call it)

twizi wrote:btw whats the cylinder

he is 3\4" aluminium pipe

Posted: Wed Jul 08, 2009 4:35 pm

by twizi

oh so the pump is a hey

ps thats weird man

Posted: Wed Jul 08, 2009 4:38 pm

by mark.f

I think that's just a result of the translation to english. He and it can be confused quite easily, if you read far_cry's other posts.

PS, good job man!

Posted: Wed Jul 08, 2009 4:50 pm

by twizi

oh so he mean it gotcha

Posted: Wed Jul 08, 2009 5:11 pm

by spudamine

Looks nice. Good work on the checkvalve, just watch that sucker for rust. mine needed rebuilding after a month, the steel bolt was severly corroded from water condensing inside the valve. used stainless the second time around.

Re: my second shock pump (full diatelas)

Posted: Wed Jul 08, 2009 6:47 pm

by boyntonstu

I finished building my new hand pump .and she work nice

the highest pressure i get from this pump is 700 psi

the cylinder is 20.7mm in diameter

Nice work.

A question about 20.7 mm and 700 psi.

20.7 mm is about 0.8" and that works out to about 0.5 sq in.

To get 700 psi out of 0.5 sq in you need to apply 350 pounds of force.

How do you apply 350 pounds of force?

How many cu in are in your chamber and how many pumps does it take to fill it?

I am following in your footsteps and I want to get it right.

BoyntonStu