Page 1 of 2

Blowgun Spud with Reload Mechanism!

Posted: Wed Jul 15, 2009 8:06 am

by frozebyte

Hey guys,

I have to credit JSR's ghetto design to give me an idea on this. Im using an air blower a.k.a blowgun to pilot this basic spud. Its made for a friend and going to have an aluminium bottle for a chamber and its barrel is a 15mm 22". Dont flame me if this idea has been thought of before, cause i chanced upon it when my barrel was a rough fit in the fitting and it looked like a good reload mech to me

Tell me if its really used before.

(magazine not included)

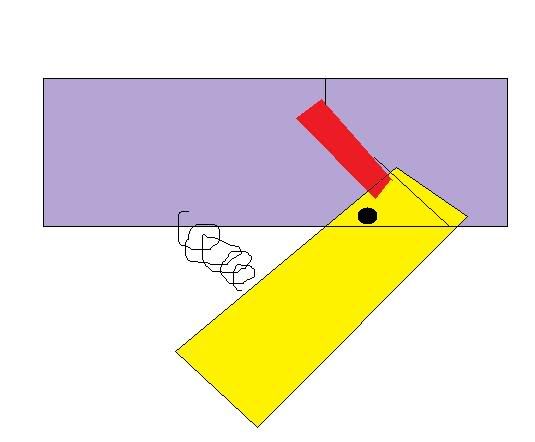

Setup

Disassembled (partially)

The magazine is a hose barb screwed on top, as whatever fits into the hose barb fits quite nicely into the barrel. I plan on making round ammo but idk how to.

The reload mechanism is basically a push out pull in thing like a shotgun. when you push out the barrel, the ammo will drop in and when you pull it back in, the ammo will be put into position by the little part of the blowgun sticking out that i didnt remove. (will upload pics of it if requested) Im not sure of its efficiency yet, but it still has lots of room for improvement!

The chamber is going to have a hole drilled in its bottom and a shrader put through and epoxied.

The reload mech is pretty cool.

Help needed on:

-Improvement of the reload mechanism

-How to make round ammo(preferrably hot glue or smth, epoxy expensive. BB's of this size?)

-Critics on design

-ANYTHING YOU DEEM FIT

CHEERS ALL!

p.s. i influenced my friend to get into spuds so i hope this would get his interest

probably showing your friend spudfiles.com and PCGUY with that monster would work on your friends too

EDIT:

paint job?

Posted: Wed Jul 15, 2009 8:23 am

by Technician1002

Nice. Only improvement I can think of is to use a flaring tool to flare the breech of the barrel (crown it) so when pulled forward to load, it can't come all the way out. Leave the flare small enough so the barrel can still push back to the closed position.

Overall, I like it. Well done.

:wav:

It's not the valve I would use for any power shooting. It is way too undersize for the barrel.

Darn it, you gave me another brainstorm and idea. Couple the loader onto a QDV that is closed with a spring. Pull barrel forward, load a round. Pull the barrel back, chamber the round and push open the QDV.

Full semi auto is possible if the air supply is left connected to the chamber. I like it. It would solve the flow problem of the small blowgun valve. I'll plan on drawing it up next week. This week is full.

How to make round ammo.. I don't. I hit the bulk food section and look for jawbreakers by the pound.

Posted: Wed Jul 15, 2009 8:34 am

by frozebyte

Flaring.. Oh yes that was what its called! Planning to flare it when i start modding it with my friend. Its the blowguns that are the most common here, its a 1/8, really really small. Im planning to flare it to the fitting's OD(best size)

I thought of the compressor idea too, its going to work very well with a compressor hooked up. Its going to have this nice reloading click-click before you're ready to fire another round. I dont have a compressor

I wanted to hook this blowgun up to something like a 1/8 or 1/4 but these fittings and pipes are uncommon.

Not sure whats a QDV but good luck on your design! Rmb to credit me if this idea is even original

kidding. But i rmb a thread where someone started flaming when a junior member got a similar idea and was accused of plagiarism and forced to put a credit. o.o

Cheers

EDIT:

Oh my whats a jawbreaker. It really dropped my jaws though, is it really that humongous and strong? Isn't it a food of some sort? We dont have it here, some round candies would work, but splatter on impact.

Posted: Wed Jul 15, 2009 8:35 am

by inonickname

Erm...JSR's was a cloud..

Valve is massively small for the barrel, so performance wont be excellent..I'm sure your friend will still have fun

Posted: Wed Jul 15, 2009 8:40 am

by frozebyte

Yep was aware its a cloud, i changed it cause my sentence was giving a wrong idea to people.

The sizes are a problem here, should try to find a supply of 1/4 fittings and 1/8pipes to get the best out of the spud.

Not going for the high power here cause i have to keep the noise down in order not to disturb the neighbours. Doesn't seem to be all that legal here. Had a thread on legality in Singapore.

Comments on reload mechanism?

Posted: Wed Jul 15, 2009 8:46 am

by inonickname

It's alright, though I doubt I could use it on my gun (as it is not secured, 400 psi from an ultra fast high flow valve would open it right up.)

An O-ring would be good to airtight it and help secure it some.

You can't really make perfectly round projectiles, unless you have a ball mill (not a pyrotechnic ball mill, one for milling round channels) and a mill to create channels. (split mold)

Posted: Wed Jul 15, 2009 8:49 am

by frozebyte

oh, will use candies for it :]

I thought of o-rings, but would be useless if it doesn't have a 'catch' for it to latch into to make it airtight, just a simple shotgun like push-pull to reload.

Plan on using it with low pressure and simple design

Posted: Wed Jul 15, 2009 11:48 am

by Technician1002

frozebyte wrote:Flaring.. Oh yes that was what its called! Planning to flare it when i start modding it with my friend. Its the blowguns that are the most common here, its a 1/8, really really small. Im planning to flare it to the fitting's OD(best size)

I thought of the compressor idea too, its going to work very well with a compressor hooked up. Its going to have this nice reloading click-click before you're ready to fire another round. I dont have a compressor

I wanted to hook this blowgun up to something like a 1/8 or 1/4 but these fittings and pipes are uncommon.

Not sure whats a QDV but good luck on your design! Rmb to credit me if this idea is even original

kidding. But i rmb a thread where someone started flaming when a junior member got a similar idea and was accused of plagiarism and forced to put a credit. o.o

Cheers

EDIT:

Oh my whats a jawbreaker. It really dropped my jaws though, is it really that humongous and strong? Isn't it a food of some sort? We dont have it here, some round candies would work, but splatter on impact.

Good luck on the flaring.

Jawbreakers are quite tough. They are a hard shelled candy. Don't try to bite them. just suck on them. Most are multi-layer with each layer a different color. They come in many sizes. The one in the photo is 1 inch. Here is a link to that one. They do disintegrate into a puff of powder if you shoot a boulder with one.

http://www.nostalgiccandy.com/index.asp ... ProdID=301

I'm waiting for the right time. I have a couple of them 2-1/4 inches in diameter

I have plans for the weekend in the woods.

The QDV is a Quick Dump Valve, a type of piston valve where the seat seal is the same diameter as the piston OD. Some info is in the wiki here;

http://www.spudfiles.com/spud_wiki/inde ... ston_valve

The cannon that broke the board is on the page with the internal valve parts.

Instead of a rope or rod to open the valve, your breech loading barrel could push it open to fire it. Yes, if I build it, I'll credit you for the inspiration. :cheers:

Posted: Thu Jul 16, 2009 3:19 am

by frozebyte

Nice split jawbreaker

Too bad they aren't available here. Gobstoppers will crush on impact i think

If the pilot of the blowgun is approxiamtely 1/4" and my barrel is 15mm, is it really that imbalanced? The ID of my barrel is 14.Xmm. How does it look?

Just something that puzzles me and i need confirmation cause i think this idea hasn't been used(I hope):

I've just checked the poll results and someone says that its been used before? Could that person or anyone else prove that it has been done before this same way, or any senior members to confirm if its really done before or not.

Posted: Sat Jul 18, 2009 5:38 am

by frozebyte

I've expanded the hole where the air vents out to push the projectile by drilling it bigger

Glad that there was enough plastic to widen it. The setup is different.

The hole has been increased from smaller than 1/8 to almost a 1/4" (fitting makes the hole slightly smaller)

Now the fitting is directly screwed in

I used my mouth's 2-3psi to test it with the small hole and had to use alot of air to push the projectile to the tip(not even shot out) of the barrel, so i decided to mod the blowgun.

Posted: Sat Jul 18, 2009 6:37 am

by inonickname

Pretty good. By the way, there are other modifications you can do to it (only if it's threaded/pull apart able).

Clicky

I found the biggest limitation with my blowgun was the flow around the poppet valve shaft. Easily remedied on a drill press with a file. The performance boost is noticeable, especially with larger pilot volumes.

The inline blowguns have a threaded part sealed by an o-ring which can be unscrewed to modify the internals. I don't know if your one does.

Good luck :thumbup:

Posted: Sat Jul 18, 2009 8:22 am

by frozebyte

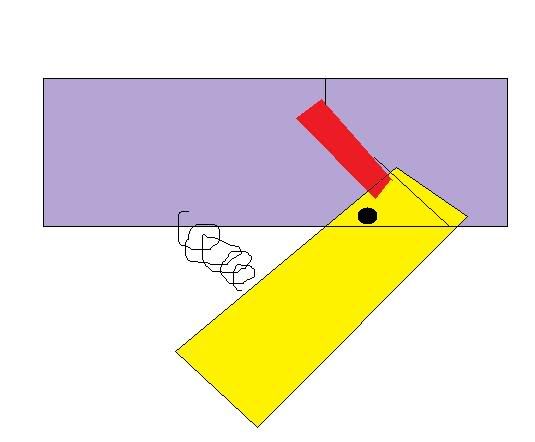

Sorry but i've got an ugly drawing of what how my blowgun works. I don't think it works like a poppet valve in those inline blowguns.

It works this way:

-Theres this stick thing that blocks the air's path when the trigger is not pressed. It works like a protruding stick that moves into the air's path.

-When the trigger is pressed, the stick moves downwards with the trigger, and the path is open.

-The spring behind the trigger creates the force that pushes the stick back into place, blocking the flow of air.

A poppet works something like a check valve right?

Heres a picture: Red:stick, yellow:trigger, purple: body, black dot: pivot

I think with this valve thats the most modifications i could do.

But the BONUS of this is that the pressure can be put on the nozzle

cause it keeps shut by this stick going bottom to top, and not a spring pushing the plug in the air flow's path (left to right?).

The explanation isn't good at all i know. Can't get an inline blowgun here

Cheers,

Froze

Posted: Sat Jul 18, 2009 9:59 am

by inonickname

That strikes me that it would only allow flow (intentionally, without leaking) in one direction, similar to a gate/flab check valve.

A poppet valve is similar to a hammer valve.

Posted: Sat Jul 18, 2009 10:17 am

by frozebyte

Im sorry again, probably the picture isn't helpful. The red thing is a stick that isn't that slant, probably a good 15degrees. Its a STICK-like thing that goes up and down, not flap like a flap. It is stuck to the trigger in a way that its like part of it.

When you press the trigger, this stick lowers itself out of the way to allow air to pass through, and when its released, it places itself back and blocks flow.

So any second thoughts on whether its a two-way?

EDIT:

I've tested it, and it works the wrong way at bicycle pump pressures. But just looking at how this works, it makes no sense if it doesn't work both ways anyway, cause the air pressure if put on either side, wont be able to open the valve

(it was a brief test only)

Posted: Sat Jul 18, 2009 10:28 am

by inonickname

I thought it was a flap. If it travels straight up and down, like a gate valve (except with a trigger) then it would work in any direction just fine.

Tell me if its really used before.

Tell me if its really used before.

probably showing your friend spudfiles.com and PCGUY with that monster would work on your friends too

probably showing your friend spudfiles.com and PCGUY with that monster would work on your friends too