Page 1 of 1

Minimum parts count cannon

Posted: Sat Oct 24, 2009 8:47 am

by boyntonstu

Counting parts:

Barrel 3/4" M copper

Chamber 3/4" M copper

3/4 Female adapter

3/4 copper T

1/2 ball valve

3/4" cap (Schrader optional)

3/4>1/2 bushing

1/2 nipple

1/2 street ell (2)

3/8 quick disconnect

3/4>1/2 Fitting reducer for valve seat

3/4 Oak piston

1/2 black faucet washer

2 "o" rings

15 or16 pieces. (3/4 copper is one piece cut into 2)

Can it be made with fewer parts?

Posted: Sat Oct 24, 2009 8:52 am

by jackssmirkingrevenge

Have you considered a

co-axial configuration?

Re: Minimum parts count cannon

Posted: Sat Oct 24, 2009 8:55 am

by spudtyrrant

yes you could have done it without the cap, schrader, tee, 3/4>1/2 bushing(you could have used a male to male),1/2" nipple, and you could have gotten a male adapting quick connect but besides that i don't see anything. may i ask why?

EDIT: oh i thought it was nvm

Posted: Sat Oct 24, 2009 9:17 am

by boyntonstu

I believe that the 180* turn around of a coax robs power.

Also, I wanted a 3/4" barrel to be able to shoot .611 marbles etc.

I may be wrong about the power, and if I am, a coax may be my next project.

I like the look an the feel of the Sten design more than a coax.

I can't explain why though.

Considering that design, could I have built it with fewer parts?

Posted: Sat Oct 24, 2009 10:27 am

by Ragnarok

boyntonstu wrote:I believe that the 180* turn around of a coax robs power.

While this is partly true, it'll be minor and not something I'd start worrying about until you've considered every other possibility for keeping up power - and I can see enough ways to coax more efficiency out of cannons that I'm not going to start chasing down this.

Indeed, although I like a cannon to be powerful, if you were to look at all of my cannons, there's one recurring theme. Some degree of ergonomics.

If they can't be practically hand fired, I don't make them. I wouldn't even consider making a cannon that was bench mounted or remote fired.

So, while something like HEAL does have its power hindered slightly by the two 45s and the 90 elbow around the back of the chamber (visible in

this picture), I'm perfectly prepared to sacrifice that insignificant amount of power for the more practical design.

Posted: Sat Oct 24, 2009 11:10 am

by boyntonstu

Ragnarok wrote:boyntonstu wrote:I believe that the 180* turn around of a coax robs power.

While this is partly true, it'll be minor and not something I'd start worrying about until you've considered every other possibility for keeping up power - and I can see enough ways to coax more efficiency out of cannons that I'm not going to start chasing down this.

Indeed, although I like a cannon to be powerful, if you were to look at all of my cannons, there's one recurring theme. Some degree of ergonomics.

If they can't be practically hand fired, I don't make them. I wouldn't even consider making a cannon that was bench mounted or remote fired.

So, while something like HEAL does have its power hindered slightly by the two 45s and the 90 elbow around the back of the chamber (visible in

this picture), I'm perfectly prepared to sacrifice that insignificant amount of power for the more practical design.

I like your HEAL very much.

My goal is ergonomics at minimum cost and complexity.

My gun is very light and easy to hold, aim, and fire.

The ball valve trigger handle needs a little more thickness for comfort and that would improve it somewhat.

According to Technician's analysis of the .wav file, the 1/2" ball valve opens fast enough to avoid the need for a QEV. That is practical..

A single shot needs to be held for just a moment.

A repeater needs to become part of you for comfort.

I was on the rifle team in college and we had to practically wear those Remington 52's.

Posted: Sat Oct 24, 2009 11:59 am

by Technician1002

boyntonstu wrote:

I believe that the 180* turn around of a coax robs power.

Not all coax designs have a 180 degree turn around. I do agree the fewer turns and twists the less loss in flow to turbulence. A valve on the breech of the chamber is often built with the 180 in tube in a tube design. It turns more to a 90 the larger the chamber diameter. When placed at the center of a large diameter chamber, the angle is only 90 degrees. I moved the valve to the barrel end on my cannons and used a large diameter chamber to make the flow as straight as possible. Measured performance is excellent.

This loss in flow is less important at lower air velocities, so the benefits of larger valves pay off by having relatively slow velocities through the bends. This is one of the reasons I'm building a larger valve cannon with about the same volume chamber. It will be used with the size of barrels I already use. The velocity through the valve will be lower in the larger area. This will result in less loss in the valve. The velocity will be higher in the barrel, hopefully.

Posted: Sat Oct 24, 2009 1:27 pm

by boyntonstu

Technician1002 wrote:boyntonstu wrote:

I believe that the 180* turn around of a coax robs power.

Not all coax designs have a 180 degree turn around. I do agree the fewer turns and twists the less loss in flow to turbulence. A valve on the breech of the chamber is often built with the 180 in tube in a tube design. It turns more to a 90 the larger the chamber diameter. When placed at the center of a large diameter chamber, the angle is only 90 degrees. I moved the valve to the barrel end on my cannons and used a large diameter chamber to make the flow as straight as possible. Measured performance is excellent.

This loss in flow is less important at lower air velocities, so the benefits of larger valves pay off by having relatively slow velocities through the bends. This is one of the reasons I'm building a larger valve cannon with about the same volume chamber. It will be used with the size of barrels I already use. The velocity through the valve will be lower in the larger area. This will result in less loss in the valve. The velocity will be higher in the barrel, hopefully.

Lower air velocities?

Do lower velocities translate to lower projectile velocities?

What would be a low air velocity beyond which bends become significant?

Posted: Sun Oct 25, 2009 12:00 am

by Gippeto

Posted: Sun Oct 25, 2009 12:16 am

by Technician1002

boyntonstu wrote:Technician1002 wrote:boyntonstu wrote:

I believe that the 180* turn around of a coax robs power.

Not all coax designs have a 180 degree turn around. I do agree the fewer turns and twists the less loss in flow to turbulence. A valve on the breech of the chamber is often built with the 180 in tube in a tube design. It turns more to a 90 the larger the chamber diameter. When placed at the center of a large diameter chamber, the angle is only 90 degrees. I moved the valve to the barrel end on my cannons and used a large diameter chamber to make the flow as straight as possible. Measured performance is excellent.

This loss in flow is less important at lower air velocities, so the benefits of larger valves pay off by having relatively slow velocities through the bends. This is one of the reasons I'm building a larger valve cannon with about the same volume chamber. It will be used with the size of barrels I already use. The velocity through the valve will be lower in the larger area. This will result in less loss in the valve. The velocity will be higher in the barrel, hopefully.

Lower air velocities?

Do lower velocities translate to lower projectile velocities?

What would be a low air velocity beyond which bends become significant?

No, this equates to being able to get lots of water out past a few rocks in a lake vs getting water past a few rocks in the rapids. One has a high elevation change due to energy loss. The other has little loss to the slow water flow. Volume is still very high.

Once it get to a smooth barrel, the full power and full speed is in the straight stretch without the loss of passing boulders at high speed upstream. Pressure entering the barrel is higher.

Less pressure was lost going through the valve obstructions.

Posted: Sun Oct 25, 2009 7:25 am

by Ragnarok

boyntonstu wrote:My gun is very light and easy to hold, aim, and fire.

A single shot needs to be held for just a moment.

I'm going to have to partly disagree on on that last one, and on a connected note, (but lesser extent) the first one.

A single shot does only need to be held for a moment, but that doesn't automatically mean ergonomics can be sacrificed. The issue here is recoil. Okay, I doubt you're dealing with all that much when firing marbles, but my cannons can kick fairly hard - and a cannon without some weight and a solid hold will make that worse. As far as recoil control, a rifle-like launcher that can be held braced into the shoulder definitely offers more.

On a similar note, I think our ideas on "easy to aim" are somewhat different. I'm sure you can be pretty confident of a hit at short range, but there's going to be a real upper limit to that.

No offence intended, but if it came down to target shooting at any real range, I have little doubt that a rifle-esque design would pull ahead.

But, I'll happily concede that for your purposes that your design is "ergonomic enough" - but on an overall scale, it's not really possible to improve on the basic principles the firearms industry has developed over centuries of design if you're looking for something that can both handle recoil and muster accuracy.

Eventually, if you want to develop things further, you'll need to decide which of ergonomics and build simplicity/cost is the greater virtue.

If you really need both, then the best option, as Jack suggests, is likely going to be a co-axial.

Posted: Sun Oct 25, 2009 7:49 am

by boyntonstu

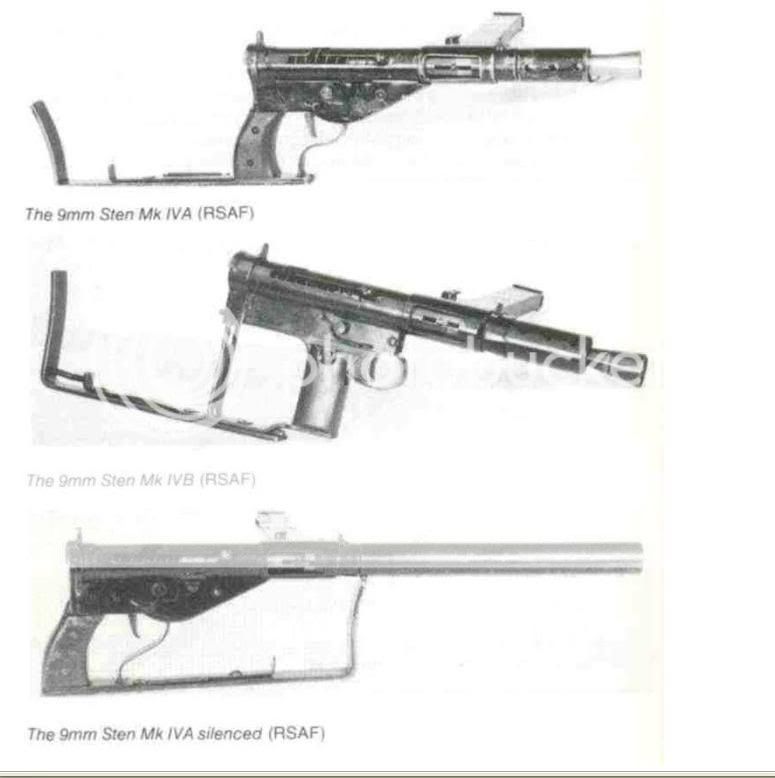

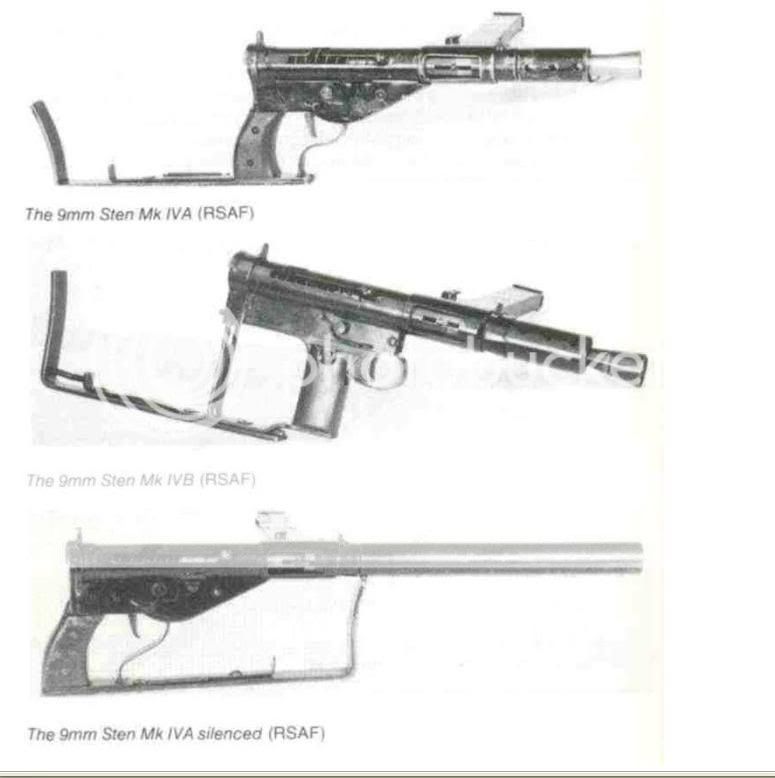

The Sten design was made by the thousands.

There are many add-ons possible to improve my gun if necessary.

BoyntonStu

Posted: Sun Oct 25, 2009 8:18 am

by Ragnarok

boyntonstu wrote:The Sten design was made by the thousands.

Millions, actually - but that doesn't mean it was notable for long range accuracy or controllability. There was a war on - the primary objective was arming as many troops as cheaply as possible.

They were made in their millions because they were the cheapest and simplest option, not because they were the best weapon - they frequently had problems.

In simple terms, they were better than having no gun, but they were far from ideal.

Posted: Sun Oct 25, 2009 10:46 am

by D_Hall

Minimum parts count would be a ball valve and a piece of pipe.

Posted: Sun Oct 25, 2009 11:56 am

by boyntonstu

Ragnarok wrote:boyntonstu wrote:The Sten design was made by the thousands.

Millions, actually - but that doesn't mean it was notable for long range accuracy or controllability. There was a war on - the primary objective was arming as many troops as cheaply as possible.

They were made in their millions because they were the cheapest and simplest option, not because they were the best weapon - they frequently had problems.

In simple terms, they were better than having no gun, but they were far from ideal.

OK

My gun has surprisingly little recoil kick. Almost zero.

(I wonder of the downward chamber position has something to do with it?)

I plan to install a laser below the barrel for aiming.

With a laser, I wouldn't have to hold the gun up at eye level to aim.

No kick, no down the barrel sighting, makes my gun ideal for me to shoot from the hip.

YMMV

BoyntonStu