Page 1 of 1

Airtight seals

Posted: Mon Nov 16, 2009 6:14 am

by rikukiakuchiki777

I've got a project on the drawing board and, seeing as how I've never used O-rings before, I wanted to get some advice. I need a 100% seal and I wont go into details but so far I've thought of these two options:

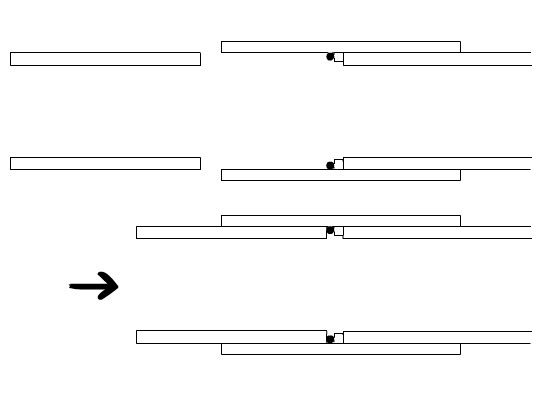

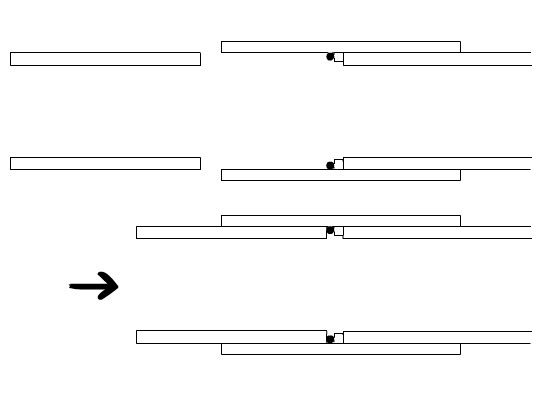

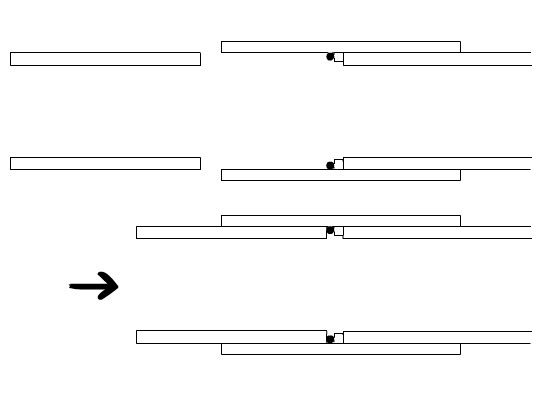

Option A:

O-ring inside sleeve, sliding piece (the left part) seals against it once pressed into the sleeve.

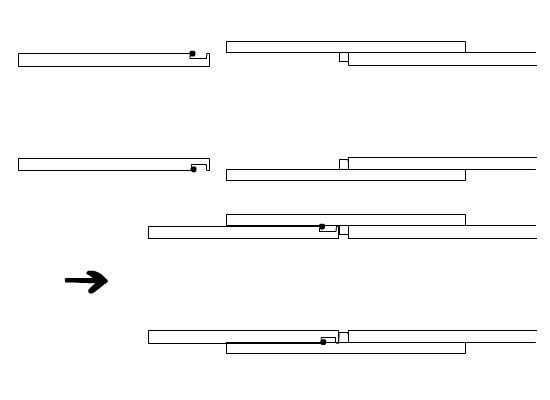

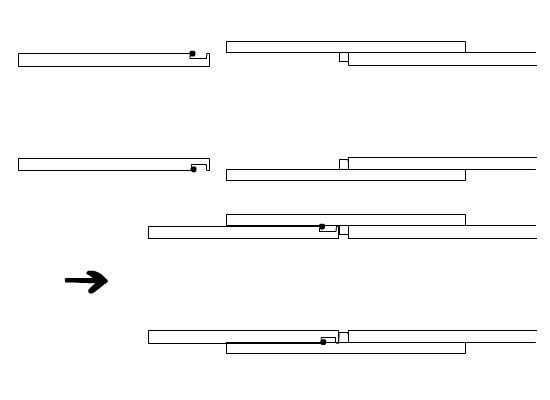

Or option B:

Floating O-ring on the left piece.

Pretty self expanatory. The left piece slides into the coupler and it needs to seal. I would prefer option A for aesthetic reasons but I'm just checking to make sure that it will give a 100% seal before I go and waste money.

Any ideas/suggestions on what will work?

Posted: Mon Nov 16, 2009 6:24 am

by qwerty

is it going to move or are you glueing it in place? for moving you just want it to be o-ringed but not floating. and for still use option A but make sure you press it tight before the glue dries.

Posted: Mon Nov 16, 2009 3:31 pm

by ramses

option A will depend a lot on the surface finish of both parts that will apply the squeezing force on the O ring. From a hacksay, this will suck and may never get to be good enough for a 100% seal.

Option B would use the already smooth outside surface of the pipe and inside surface of the coupler. It would also weaken the pipe that goes into the coupler significantly. It would not require nearly as much force pushing the pipe into the coupler. It should be lubricated. I would go with a floating O-Ring, as I have had problems with non-floating O-rings.

I would go with B, especially if any twisting is involved (rifle style bolt action)

Edit: yeah i meant B

Posted: Tue Nov 17, 2009 6:02 am

by rikukiakuchiki777

ramses wrote:I would go with A, especially if any twisting is involved (rifle style bolt action)

I take it you meant option B?

qwerty wrote:is it going to move or are you glueing it in place?

Yes. To clarify, it will be moving.

The coupler will be sanded out so it won't be difficult to slide in/out. It just needs to seal once it is in there.

Posted: Tue Nov 17, 2009 9:42 am

by D_Hall

I doubt option A will seal reliably if for no other reason than it'll find itself bumped and out of position (nothing to hold it in place).

B isn't bad.

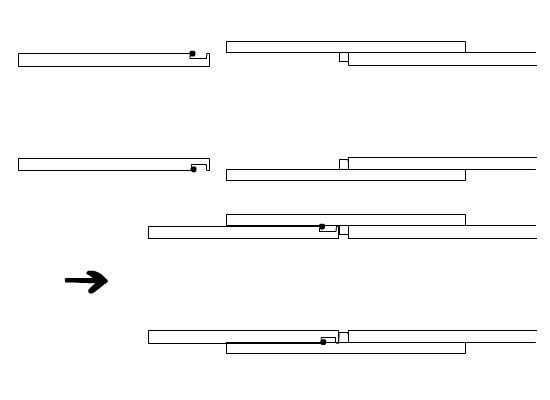

How about an option C? Where you machine an oring groove into the inside of the coupler (or whatever the larger diameter piece is)? That should give you a more reliable seal than A while maintaining it's asthetics.

Posted: Tue Nov 17, 2009 9:43 am

by D_Hall

qwerty wrote:is it going to move or are you glueing it in place? for moving you just want it to be o-ringed but not floating.

Huh? Do an o-ring joint properly and even in dynamic seals there's no need to glue them in place.

Posted: Tue Nov 17, 2009 10:51 am

by jrrdw

Double o-ring it. In option A you have it placed where the stationary pipe ends, (cut a o-ring groove there like D_Hall suggest). Then place a o-ring 1/2" from the end of the moving pipe, (non floating, just a standard o-ring groove). Careful sanding out the coupler, give it to much room and you could wind up blowing the o-ring/s out.

Posted: Tue Nov 17, 2009 11:33 am

by qwerty

Huh? Do an o-ring joint properly and even in dynamic seals there's no need to glue them in place.

I meant the pipe