Is this a good Coax design?

Posted: Fri Oct 15, 2010 9:31 pm

I've been reading on the site for a while, and while I've built some basic cannons, nothing special has been wrought by these hands, I have built a basic Over-under ball valve pneumatic, a metered butane 1" bore combustion, and a more advanced metered butane golfball gun:

http://s771.photobucket.com/albums/xx35 ... C_8948.jpg

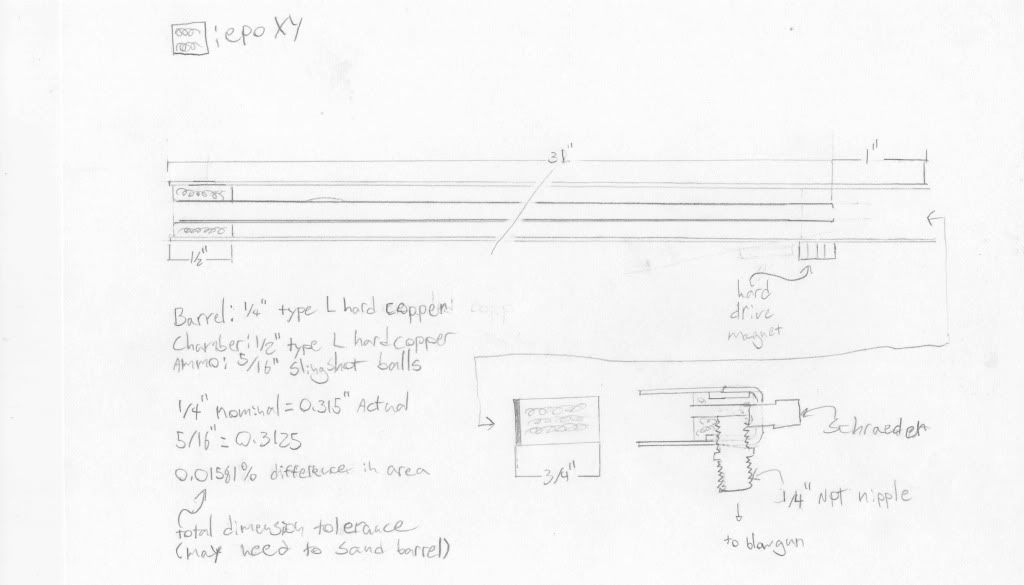

now I am planning something a little more special, I want to build a copper piston musket (I mean, can't use "rifle") and want a little input, primarily on epoxy (JSR?)

The image should hopefully speak for itself, a few notes and questions:

1. the thing with "Schraeder" and "1/4" NPT nipple" pointing to it is an endcap and coupler with a little pipe between them, filled with epoxy, drilled and tapped.

2. I hope to solder the coupler to the end of the pipe, will the joint hold up to the piston's force?

3. in soldering it, will it melt or otherwise damage the epoxy?

4. would it be easier to find some 5/8" rod and drill and tap that and use a coupler between the barrel and rod?

5.What pressure would i need to achieve to get a speed near 120m/s (just under Canadian classification of a firearm)?

6.the magnets is to hold the ball bearings in place before firing, they can easily act on a >1g object at 1/4" away

I am looking to build a stock, based on this:

http://www.spudfiles.com/forums/draguno ... 21623.html

and attach a rail and scope, hoping i can get accuracy to justify it

If my handwriting is illegible, or if you have any other questions, let me know.

http://s771.photobucket.com/albums/xx35 ... C_8948.jpg

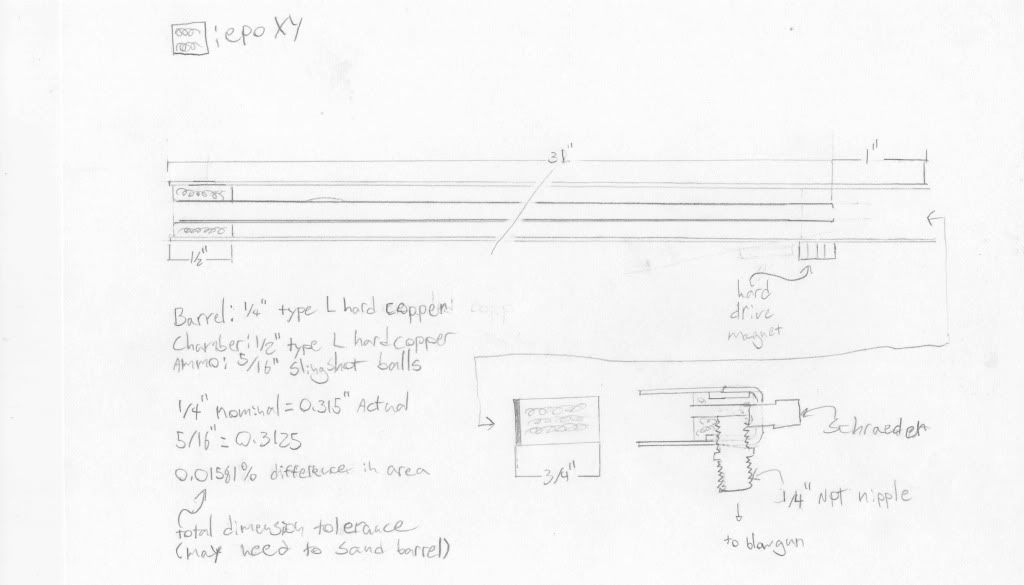

now I am planning something a little more special, I want to build a copper piston musket (I mean, can't use "rifle") and want a little input, primarily on epoxy (JSR?)

The image should hopefully speak for itself, a few notes and questions:

1. the thing with "Schraeder" and "1/4" NPT nipple" pointing to it is an endcap and coupler with a little pipe between them, filled with epoxy, drilled and tapped.

2. I hope to solder the coupler to the end of the pipe, will the joint hold up to the piston's force?

3. in soldering it, will it melt or otherwise damage the epoxy?

4. would it be easier to find some 5/8" rod and drill and tap that and use a coupler between the barrel and rod?

5.What pressure would i need to achieve to get a speed near 120m/s (just under Canadian classification of a firearm)?

6.the magnets is to hold the ball bearings in place before firing, they can easily act on a >1g object at 1/4" away

I am looking to build a stock, based on this:

http://www.spudfiles.com/forums/draguno ... 21623.html

and attach a rail and scope, hoping i can get accuracy to justify it

If my handwriting is illegible, or if you have any other questions, let me know.