I've brainstormed for ages to think of good designs for pneumatic guns, and thanks to some inspiration from here I have plenty now... Lets say you could just give me some parts and I can build some high FPS full auto portable bb gun... But the #1 problem is;

I don't have the experience

The motivation (because everything I try to build, fails)

And most of all; the only stuff you can get here is crap... (no blowguns, sprinkler valves, etc)

I have dozens of half-finished projects, but neither fully finished due my lack of parts and experience building one...

In a last attempt of building a succesful piston gun... I've come up with a very simple project to build a small, easy and effective small piston gun.

If this one fails I might give up building pneumatics

Could you guys give me some tips on building a very basic piston gun?

Here are my plans; is it okay?

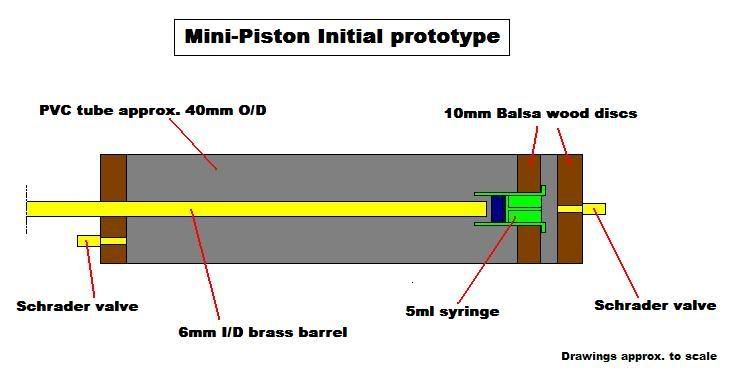

In the pic below:

-Most likely the piston will be (hot) glue/candle wax, (bad idea?)

-The other olive-green stuff is epoxy

-Chamber and cap will be made of PVC, barrel from some other material

-Pilot valve is a modded lighter head (pretty good flow)

-Piston sealing face; some squishy rubber

-Bikevalve to pump it up

-Purple stuff is lube (be will vaseline or sewing-machine oil)

(click to enlarge)

It's detailed to make sure you guys can understand every part and can easily see what's wrong or not... (And I used to pixel-art

That's it, any tips/alternative materials/warnings?

Thanks for reading and please reply...