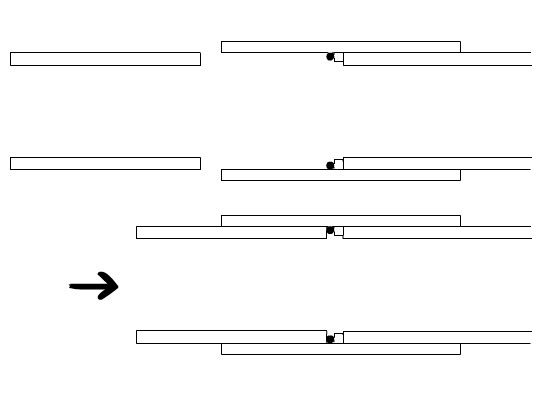

Option A:

O-ring inside sleeve, sliding piece (the left part) seals against it once pressed into the sleeve.

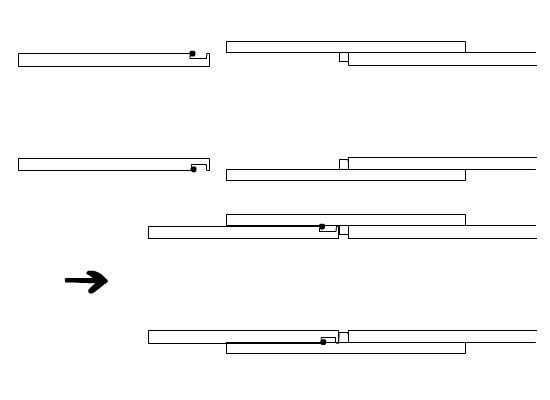

Or option B:

Floating O-ring on the left piece.

Pretty self expanatory. The left piece slides into the coupler and it needs to seal. I would prefer option A for aesthetic reasons but I'm just checking to make sure that it will give a 100% seal before I go and waste money.

Any ideas/suggestions on what will work?