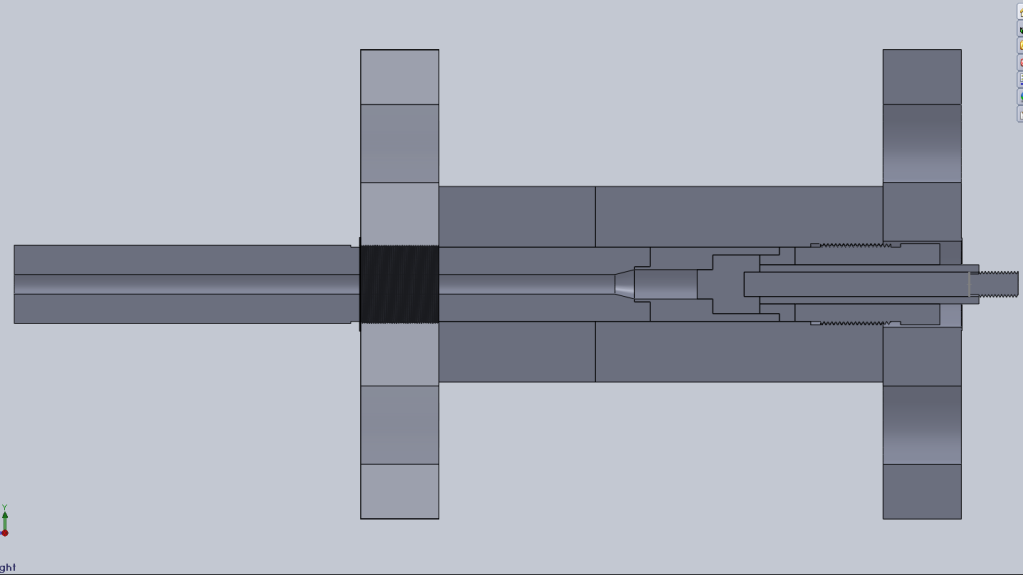

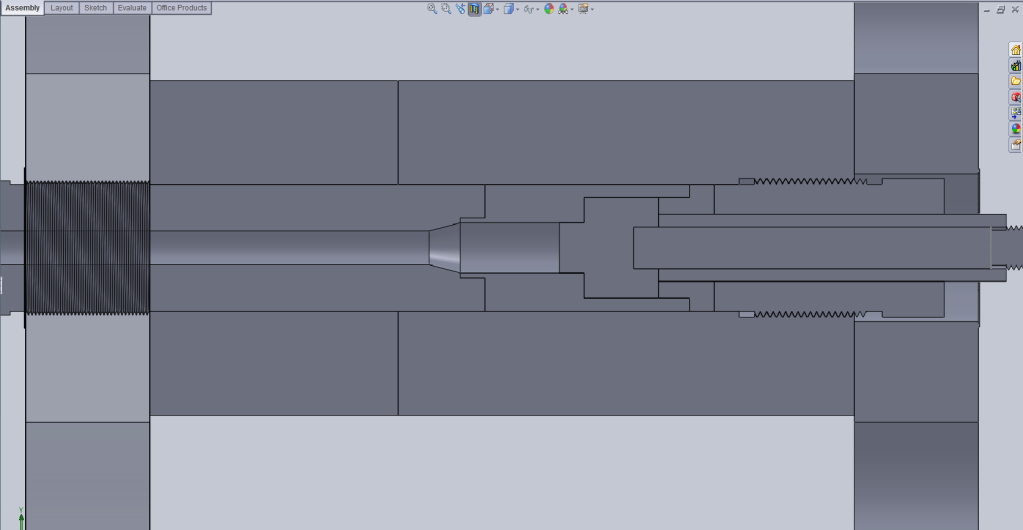

Sharpshooter: center drills are not for starting drilled holes, they are for, as the name suggests, producing a shallow conical hole to accept a live center. After doing the outside of the barrel, the hole will be made as follows:

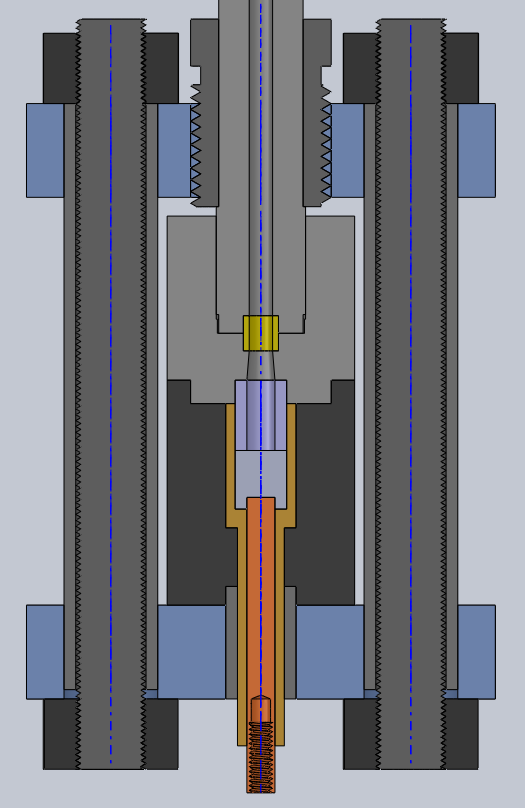

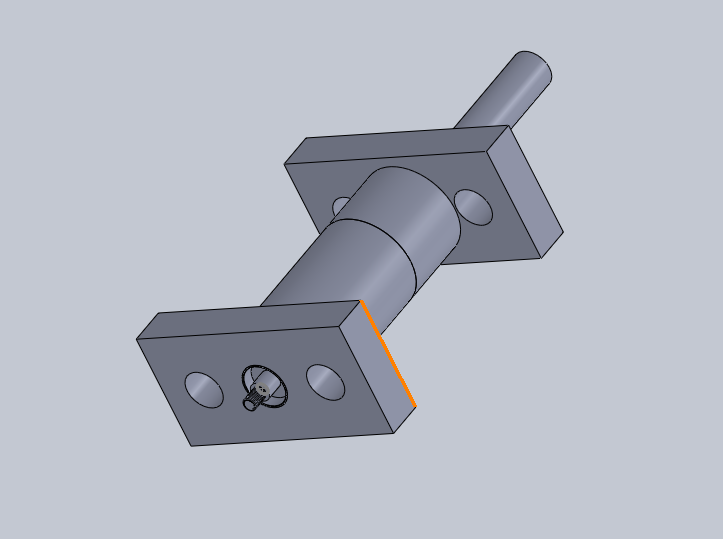

Start hole with spotting drill, bore to achieve roundness and straightness of the starting hole, drill in 1" increments with extension drill (having flutes on only the last 2" or so), chase 1" behind that one with an all-flute extension drill 1/64" larger, then ream to .250" after the drilling operation. It won't be as straight as could be done with a gun drill or BTA system, but it's the best I can do, and the bore should be very smooth.

al-xg: That's what I'm asking you

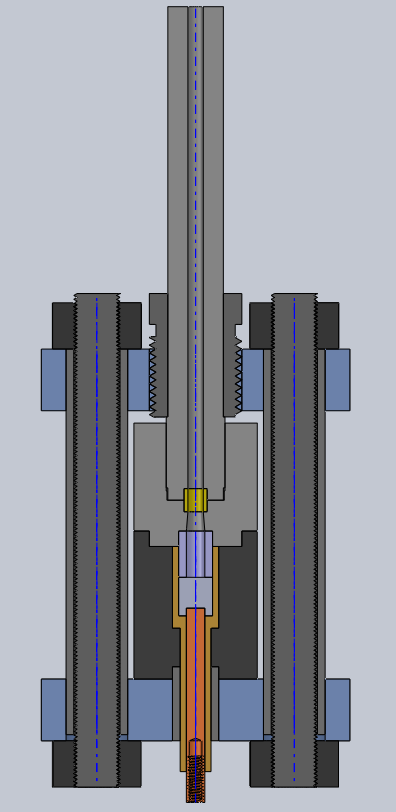

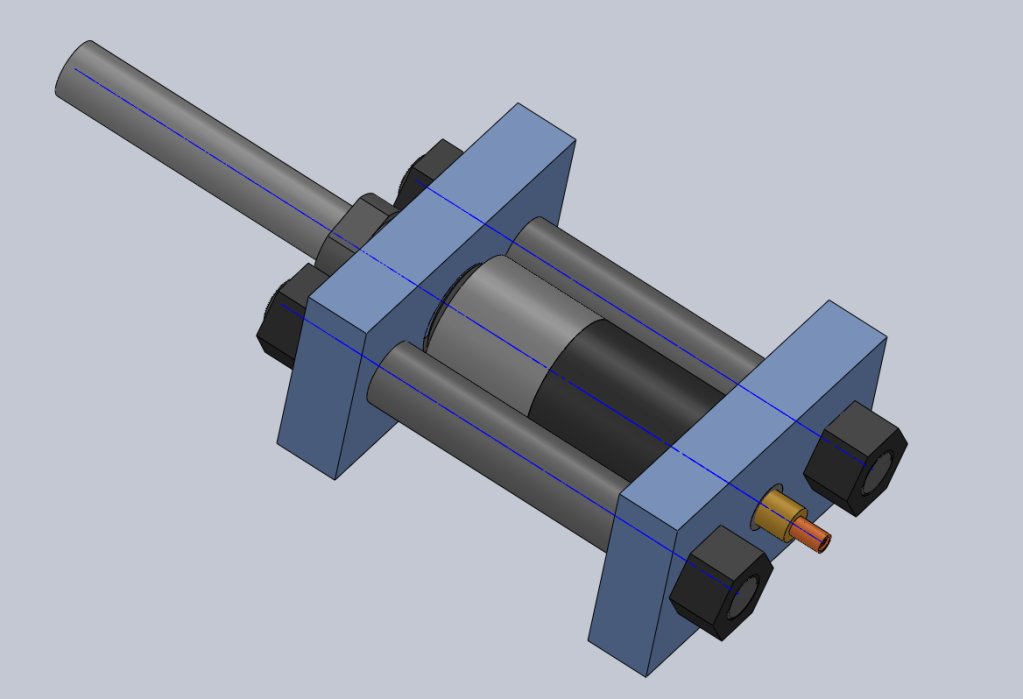

The insulator will clearly be extruded out the back a little bit during a normal shot, but prior experience says that this won't be nearly enough to cause gross failure. For failure to happen in that section, the .550" diameter electrode (likely a Cu-W alloy for the final build) would have to be pushed through the 0.500" hole in the rear casing, which will be normalized 4340 steel initially.

Do you see other likely failure modes? Do you think this one is more worrisome than I do?

Spudfiles' resident expert on all things that sail through the air at improbable speeds, trailing an incandescent wake of ionized air, dissociated polymers and metal oxides.