Ball Valve Question!

- doomburger

- Private 3

- Posts: 48

- Joined: Fri Jul 27, 2012 7:07 am

Hey guys! I'm buying a 2.5" PVC ball valve (can't find a sprinkler valve anywhere) for my spud gun, and someone has told me that after a while it starts to become stiff and harder to turn. Is this true, and if it is, around how long does it last until it starts to become stiff?

- doomburger

- Private 3

- Posts: 48

- Joined: Fri Jul 27, 2012 7:07 am

Ah thanks. I have a bottle of silicon spray right next to me!  I'm not building a piston because a ball valve is so much simpler

I'm not building a piston because a ball valve is so much simpler

However, I have a problem: How am I supposed to lube the ball valve if there are tubes on both sides? (I can't reach the ball valve)

However, I have a problem: How am I supposed to lube the ball valve if there are tubes on both sides? (I can't reach the ball valve)

- jackssmirkingrevenge

- Five Star General

- Posts: 26219

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 582 times

- Been thanked: 348 times

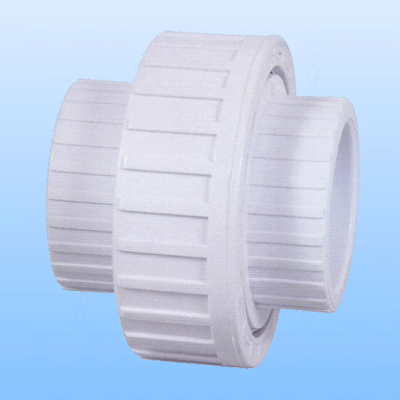

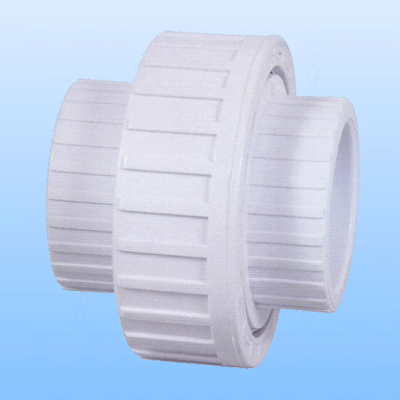

can you find a union?

Because if so, screw ball valves, go burst disk!

From another thread:

If you want a high performance big bore without breaking the bank, consider something like this design:

You can make the chamber and barrel out of the same type of tubing, all you need is the chamber capped on one end with a valve of some sort in order to supply the air, and on the other end you attach a union.

All you have to do is sandwich a disk of frangible material (foil etc.) and when a certain pressure is reached in the chamber, BOOM!, Robert's your mother's brother.

It is a bit of a pain in the arse having to install new burst disks for every shot but really this is the only way to get the best performance out of a pneumatic on a very low budget.

At 100-150 psi with a long enough chamber and barrel, performance should be quite impressive.

Because if so, screw ball valves, go burst disk!

From another thread:

If you want a high performance big bore without breaking the bank, consider something like this design:

You can make the chamber and barrel out of the same type of tubing, all you need is the chamber capped on one end with a valve of some sort in order to supply the air, and on the other end you attach a union.

All you have to do is sandwich a disk of frangible material (foil etc.) and when a certain pressure is reached in the chamber, BOOM!, Robert's your mother's brother.

It is a bit of a pain in the arse having to install new burst disks for every shot but really this is the only way to get the best performance out of a pneumatic on a very low budget.

At 100-150 psi with a long enough chamber and barrel, performance should be quite impressive.

hectmarr wrote:You have to make many weapons, because this field is long and short life

Jack's right, barring valveless that's the highest performance you can get from a pneubmatic. Chuck in a spark gap and you've got the option for a very low mix hybrid or combustion.

To lubricate the ball valve if you can't be convinced out of it, spray the silicone onto a rag, and poke it down against the BV, then rotate it a few times.

To lubricate the ball valve if you can't be convinced out of it, spray the silicone onto a rag, and poke it down against the BV, then rotate it a few times.

/sarcasm, /hyperbole

- doomburger

- Private 3

- Posts: 48

- Joined: Fri Jul 27, 2012 7:07 am

No luck with finding any unions either...

How can I lube a ball valve with tubes on both ends???

How can I lube a ball valve with tubes on both ends???

- jackssmirkingrevenge

- Five Star General

- Posts: 26219

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 582 times

- Been thanked: 348 times

This method also works for unclean members of the fairer sexZeus wrote:Tie the rag to a stick and poke it down.

hectmarr wrote:You have to make many weapons, because this field is long and short life

- doomburger

- Private 3

- Posts: 48

- Joined: Fri Jul 27, 2012 7:07 am

Ah thanks, I guess I'll do that. You only need to lubricate one side of the ball valve?

Hahajackssmirkingrevenge wrote:This method also works for unclean members of the fairer sexZeus wrote:Tie the rag to a stick and poke it down.

- doomburger

- Private 3

- Posts: 48

- Joined: Fri Jul 27, 2012 7:07 am

To lubricate the other side as well, the ball valve would have to turn at least 180 degrees...

I am under the impression that ball valves can only turn 90 degrees. Right?

EDIT: My ball valve looks somewhat like this

http://www.spudfiles.com/spud_wiki/inde ... _valve.jpg

I am under the impression that ball valves can only turn 90 degrees. Right?

EDIT: My ball valve looks somewhat like this

http://www.spudfiles.com/spud_wiki/inde ... _valve.jpg

- doomburger

- Private 3

- Posts: 48

- Joined: Fri Jul 27, 2012 7:07 am

Ah I see now! you have enlightened me  Thanks!

Thanks!

Create an account or sign in to join the discussion

You need to be a member in order to post a reply

Create an account

Not a member? register to join our community

Members can start their own topics & subscribe to topics

It’s free and only takes a minute

Sign in

-

- Similar Topics

- Replies

- Views

- Last post

-

- 8 Replies

- 2290 Views

-

Last post by Dornep

-

- 2 Replies

- 1138 Views

-

Last post by dudeman508

-

- 7 Replies

- 2640 Views

-

Last post by Pibster

-

- 2 Replies

- 900 Views

-

Last post by Technician1002

-

- 17 Replies

- 7311 Views

-

Last post by OuchProgramme