Ive been researching revolver mechanisms for another project and saw an OLD volly gun

with seven barrels. Now I searched here but found nothing. Why not ! Im starting one tonight

with three .30 caliber barrels in a coaxial , then seeing if i like it ill try a seven barreled .25.

So , has any one tried this ?You all have any opinions or ideas on the matter?

Seven barrels in a coaxial ? Volly gun concept ?

- jackssmirkingrevenge

- Five Star General

- Posts: 26219

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 582 times

- Been thanked: 348 times

http://www.spudfiles.com/pneumatic-cann ... c6977.html

pro - easier than having to make shotgun wads

con - pain in the ass to load

pro - easier than having to make shotgun wads

con - pain in the ass to load

hectmarr wrote:You have to make many weapons, because this field is long and short life

Main question is why not just fire a bunch of pellets like a shotgun from one barrel.

- jackssmirkingrevenge

- Five Star General

- Posts: 26219

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 582 times

- Been thanked: 348 times

Toit! We need to see some media of your devices in action!

2) since it is much less likely that there will be interaction between the projectiles in flight, it should print much tighter groups than a group of projectiles in a single barrel.

1) unless you have them ready-made, the fabrication of good wads is usually a pain in the posterior.Main question is why not just fire a bunch of pellets like a shotgun from one barrel.

2) since it is much less likely that there will be interaction between the projectiles in flight, it should print much tighter groups than a group of projectiles in a single barrel.

hectmarr wrote:You have to make many weapons, because this field is long and short life

@hotwired[center][/center] - That only results in disappointment and a mess to clean.

@jack- Both your points are infact why I had to make one and see !

Best I can show today is a four shot group , only one shot of the four spread out about

1.5" . I think thats almost too tight , however I was only 15 feet away.

I think at 30 feet it will pattern nicely!

@jack- Both your points are infact why I had to make one and see !

Best I can show today is a four shot group , only one shot of the four spread out about

1.5" . I think thats almost too tight , however I was only 15 feet away.

I think at 30 feet it will pattern nicely!

- jackssmirkingrevenge

- Five Star General

- Posts: 26219

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 582 times

- Been thanked: 348 times

Sweet. What pressures do you reckon you're generating? A small pressure gauge would be a cheap and easy addition to the chamber.

hectmarr wrote:You have to make many weapons, because this field is long and short life

I am sad to say this but.... If the loads fit differently ( one fits kinda tight and the other rolls down the barrel) the tighter load will not fire, who invented this idea? It is a nice concept, but the problem is that each barrel should have its own chamber so that the above problem doesn't happen.

when life gives you lemons... make root beer and leave the world wondering how you did that

@jack- Well this pump is the largest diameter I've made with the piston at 1" o.d. ( I use 3/4" or 1/2" normally ) because i wanted lots of air. Every stroke of this size puts 15 psi it seems so the limiting factor is your comfort and saftey. Six pumps hit the 70 psi mark on the gauge , I can do nine pumps before having to put it on my foot for leverage. Of course I respect the limits of pvc.

The pistol in the photo is my first prototype grip and trigger designed to fit all my other guns. Its engineered wood and pcv.

@dartguy - hehe , your sad huh? Im grinning ear to ear , but not because your sad! And it my intelectual property , i inventerized it! .So don't make one.

The pistol in the photo is my first prototype grip and trigger designed to fit all my other guns. Its engineered wood and pcv.

@dartguy - hehe , your sad huh? Im grinning ear to ear , but not because your sad! And it my intelectual property , i inventerized it! .So don't make one.

No prob, I'll just try to build my land mines, hand grenades, and bolt action cartridge pcp dart rifle. I have some cool ideas but can't put them together from lack of cash

when life gives you lemons... make root beer and leave the world wondering how you did that

- jackssmirkingrevenge

- Five Star General

- Posts: 26219

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 582 times

- Been thanked: 348 times

Not bad! Though for a given quantity of air, high pressure low volume gives more power than low pressure high volume. Small bore pumps and metal construction is the way to go if power is what you're after.dajoro wrote:Well this pump is the largest diameter I've made with the piston at 1" o.d. ( I use 3/4" or 1/2" normally ) because i wanted lots of air. Every stroke of this size puts 15 psi it seems so the limiting factor is your comfort and saftey. Six pumps hit the 70 psi mark on the gauge , I can do nine pumps before having to put it on my foot for leverage. Of course I respect the limits of pvc.

Pay no attention to the man behind the curtainhehe , your sad huh? Im grinning ear to ear , but not because your sad! And it my intelectual property , i inventerized it! .So don't make one.

hectmarr wrote:You have to make many weapons, because this field is long and short life

""Not bad!""

Thank you jack- I couldn't have done it without your epoxy inspiration! And the copper pistol having a small dia. pump is a wicked little beast , but I need to start looking at my crossman pump arm assembly again and figure out how i can use that idea. I need more leverage for more power! Its always looked simple enough, but we'll see. I think its time to go "all-metal-higher-pressure" on some of my designs.

The seven brass .25" tubes arrived special order and are just sitting there waiting ....

Thank you jack- I couldn't have done it without your epoxy inspiration! And the copper pistol having a small dia. pump is a wicked little beast , but I need to start looking at my crossman pump arm assembly again and figure out how i can use that idea. I need more leverage for more power! Its always looked simple enough, but we'll see. I think its time to go "all-metal-higher-pressure" on some of my designs.

The seven brass .25" tubes arrived special order and are just sitting there waiting ....

- jackssmirkingrevenge

- Five Star General

- Posts: 26219

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 582 times

- Been thanked: 348 times

It's stories like these that in a cold, dark Quebec winter, warm the cockles of my heartdajoro wrote:Thank you jack- I couldn't have done it without your epoxy inspiration!

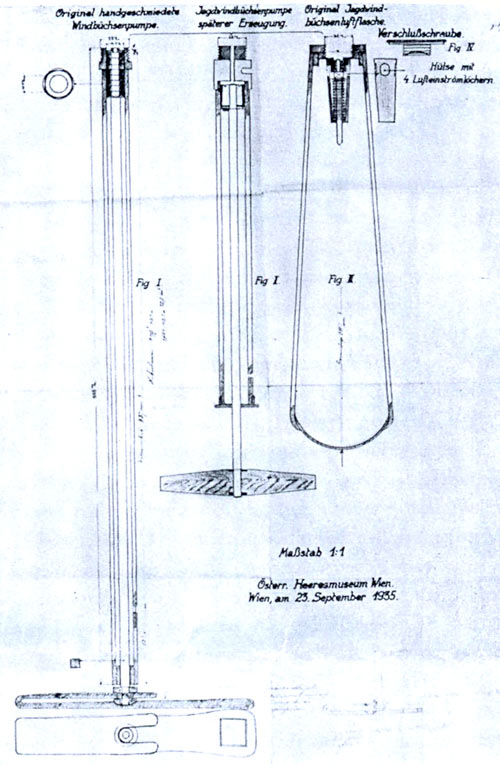

Levers are not necessary for high pressures, look at the Girandoni:And the copper pistol having a small dia. pump is a wicked little beast , but I need to start looking at my crossman pump arm assembly again and figure out how i can use that idea. I need more leverage for more power! Its always looked simple enough, but we'll see. I think its time to go "all-metal-higher-pressure" on some of my designs.

It is a simple stirrup pump but capable of reaching pressures in excess of 750 psi by virtue of its small bore, long stroke and efficient design.

hectmarr wrote:You have to make many weapons, because this field is long and short life

NICE LINK ! The internal diagrams of the trigger mechanism I have not seen before. Lots of ideas there . I'm working toward high pressure with as few pump strokes as possible , in single shot for now. This model gets 110 psi. in five strokes in a .25 caliber, enough to punch the bottom of a coke can and out the side at 20' .I tried fixing the first photo with no luck...

Create an account or sign in to join the discussion

You need to be a member in order to post a reply

Create an account

Not a member? register to join our community

Members can start their own topics & subscribe to topics

It’s free and only takes a minute

Sign in

-

- Similar Topics

- Replies

- Views

- Last post