and a vid

hectmarr wrote:You have to make many weapons, because this field is long and short life

hectmarr wrote:You have to make many weapons, because this field is long and short life

<a href="">DONT TAZE ME BRO.. DONT TAZE ME... AHHHH</a>Yea, that's definitely going to get you at least a tazer.

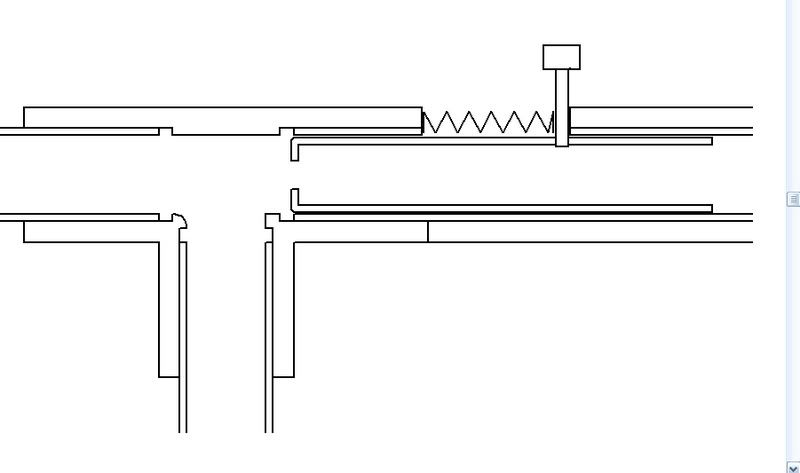

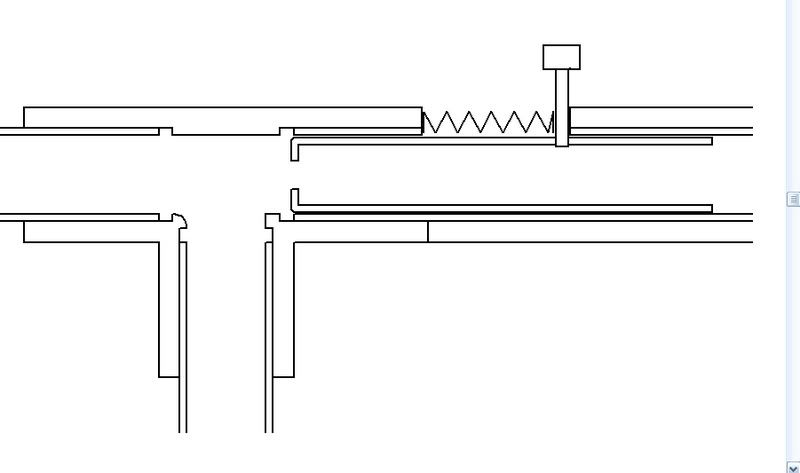

Maybe doing away with restrictor hole completely and adding a homemade check valve to the front, making the tension on the check valve just enough so that it opens when the bolt is fully closed.Hailfire753 wrote:...For your bolt, to increase performance you should increase the restrictor hole size as much as possible while making sure it still works.

You need to be a member in order to post a reply

Not a member? register to join our community

Members can start their own topics & subscribe to topics

It’s free and only takes a minute