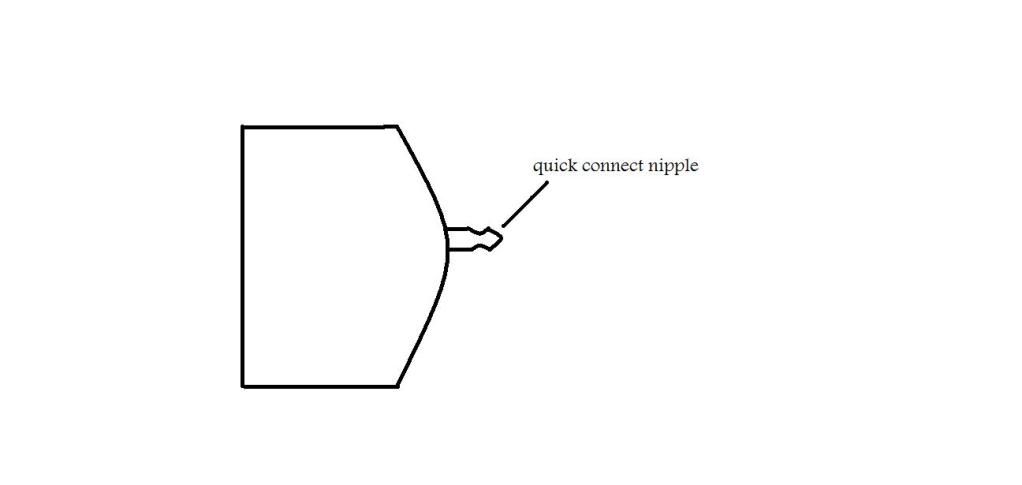

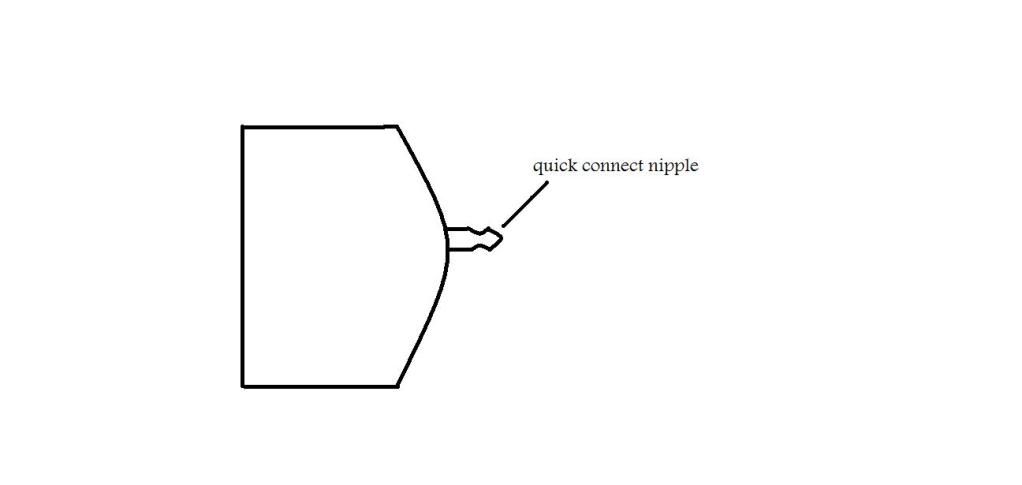

this is what nipple looks like

it has to hold 150 psi without leaking and so it will hook up directly to the cap for constant air flow

You need to be a member in order to post a reply

Not a member? register to join our community

Members can start their own topics & subscribe to topics

It’s free and only takes a minute