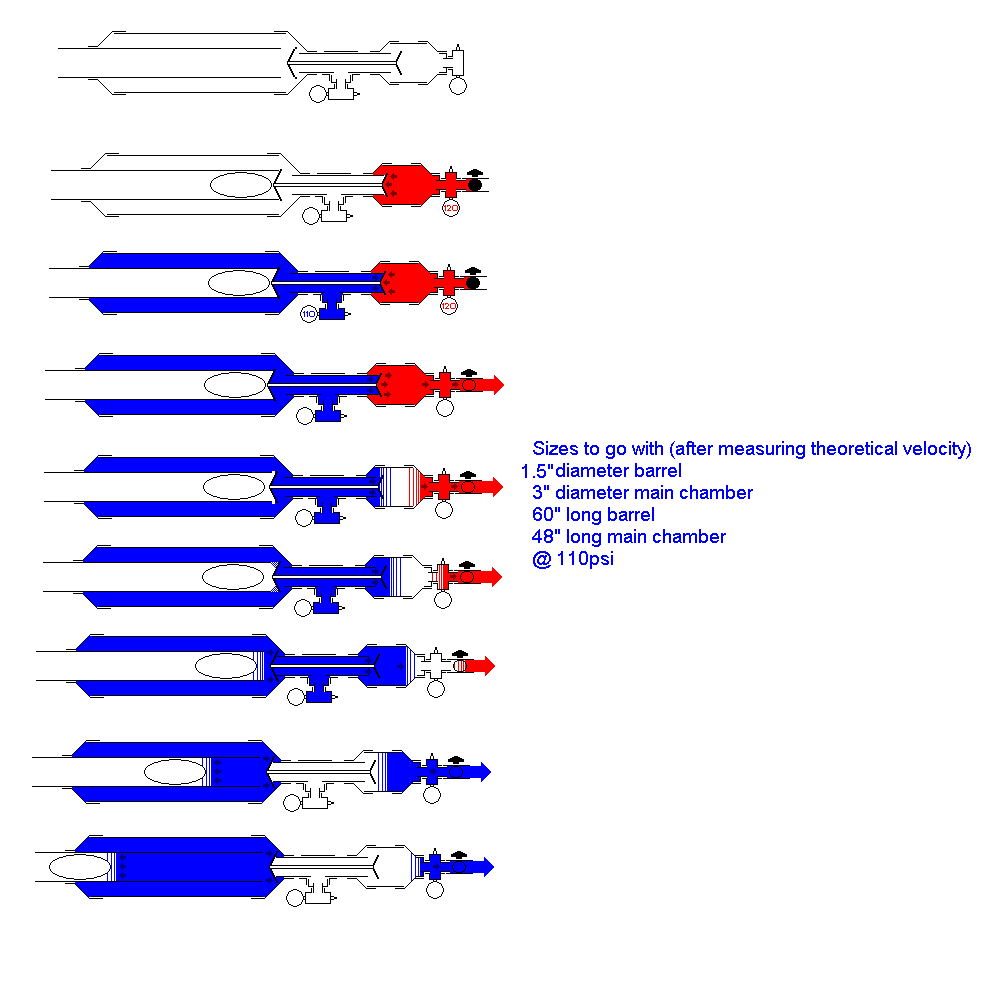

Blue = air @ 110psi

Red = air @ 120psi

If the pressure on both sides of the "piston"(though it's more of a cap or top) is at equilibrium, then the cannon has the chance to misfire, either from being jolted, dropped, or a possible air leak that might make the smaller chamber's psi less than the larger's, which would also cause a misfire.jrrdw wrote: Why use two different pressure's though?

You need to be a member in order to post a reply

Not a member? register to join our community

Members can start their own topics & subscribe to topics

It’s free and only takes a minute