Blow forward barrel

- Lockednloaded

- Staff Sergeant

- Posts: 1566

- Joined: Thu Sep 03, 2009 9:38 pm

- Location: Texas, USA

- Been thanked: 7 times

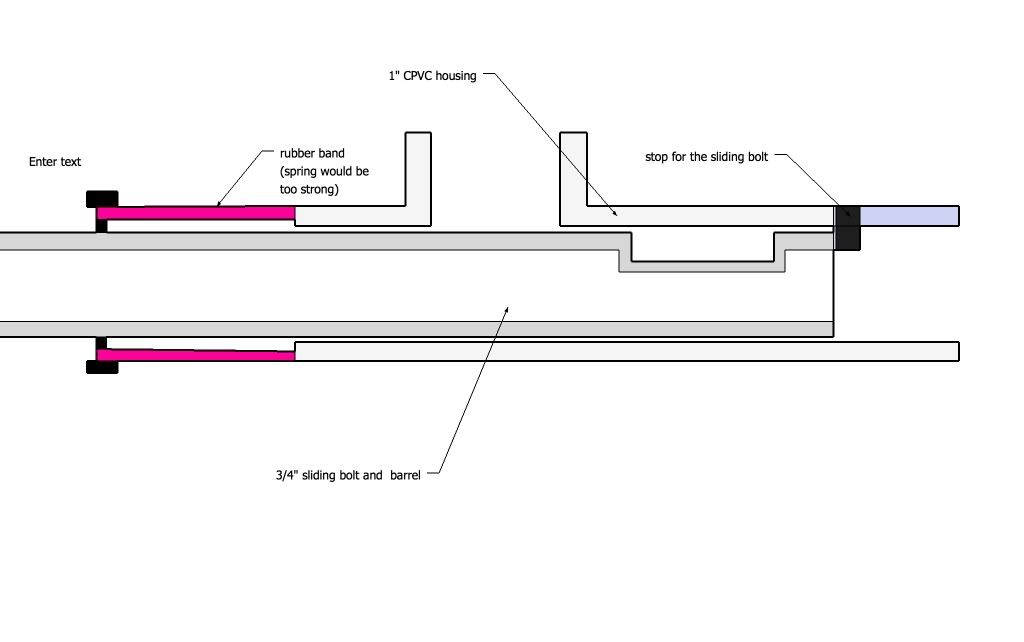

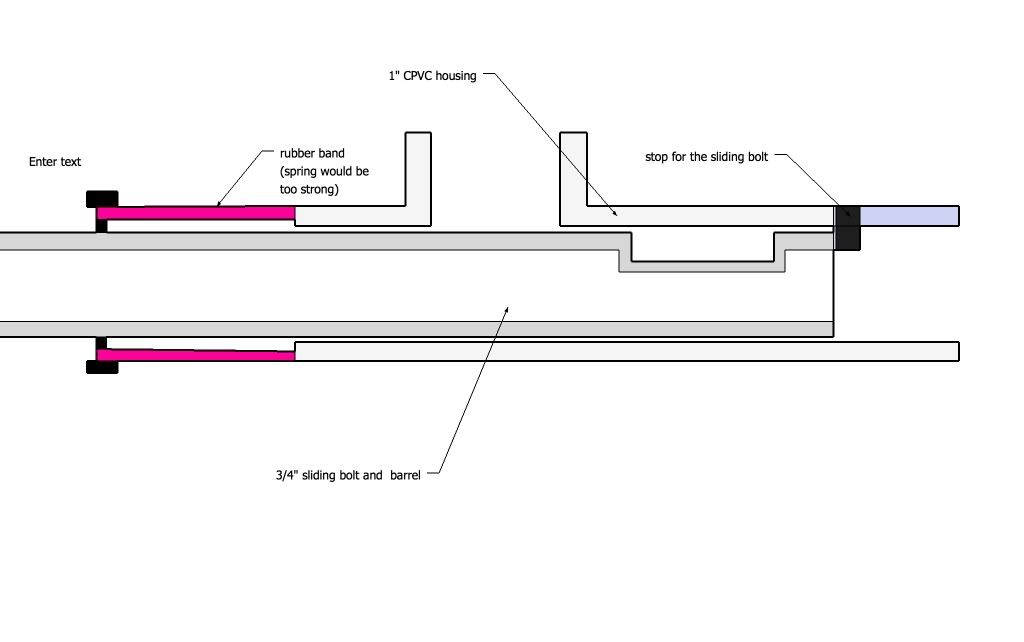

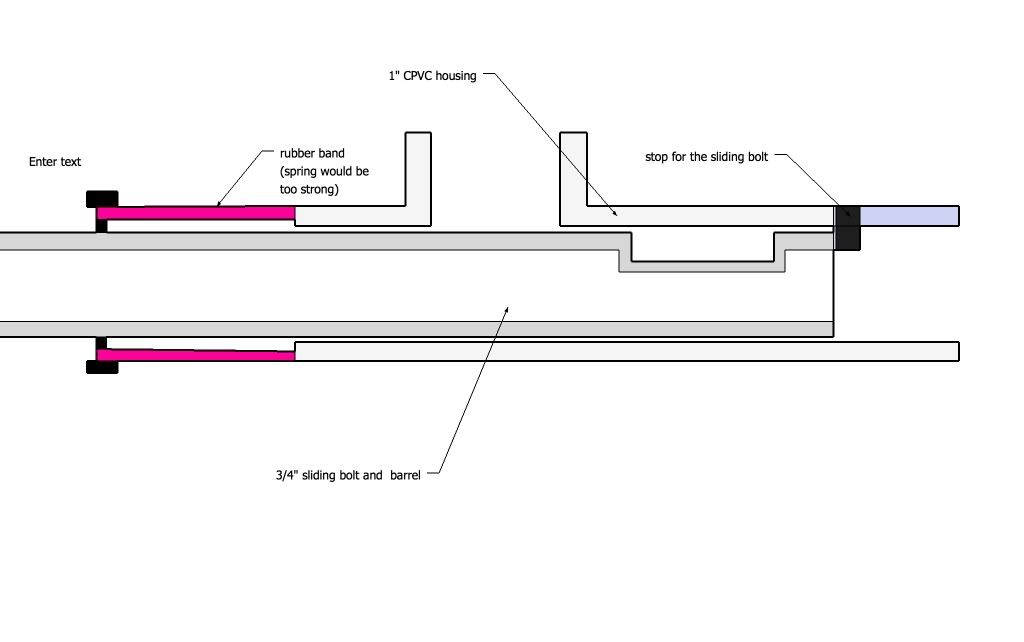

Well I've finally put together the blow forward barrel mechanism, but despite it looking totally awesome when it cycles, Its having a lot of problems. I made it with out o-rings, just the fairly snug fit between 3/4" and 1" cpvc. The barrel blows forward everytime, but for some reason it needs an air tight mag to feed ammo. I want to be able to use a hopper for it, but that won't work with the current design. Any suggestions?

- clemsonguy1125

- Sergeant 5

- Posts: 1485

- Joined: Tue Jul 21, 2009 4:00 pm

- Location: East Coast

Not sure about your problem but what causes the barrel to blow forward, would air just come straight out the barrel

take a look at JSR's work with blow forward..

he put a stop at the end of the bolt housing, so that no air went through the bolt until a round was in. So basically, the bolt moved down the stop, with no air getting through, until the bolt cleared the stop, then air was free to go down the bolt.

he put a stop at the end of the bolt housing, so that no air went through the bolt until a round was in. So basically, the bolt moved down the stop, with no air getting through, until the bolt cleared the stop, then air was free to go down the bolt.

"Some say his pet elephant is pink, and that he has no understanding of "PG rated forum". All we know is, he's called JSR. "

- clemsonguy1125

- Sergeant 5

- Posts: 1485

- Joined: Tue Jul 21, 2009 4:00 pm

- Location: East Coast

His sketch doesn't show one end of the barrel being blocked though. I don't know if you were talking to me or him.

- Gaderelguitarist

- Corporal

- Posts: 580

- Joined: Sat Aug 16, 2008 9:56 pm

- Location: Columbia, MD

- Contact:

I'm not sure exactly what thread it was in the past, but someone built a blow forward bolt with no more than the edge surface area of the pipe wall for the air to act on and it worked.what causes the barrel to blow forward, would air just come straight out the barrel

Air is probably escaping through your mag port and preventing a full cycle of the bolt. At least thats how I see it.

so many muchness

- Lockednloaded

- Staff Sergeant

- Posts: 1566

- Joined: Thu Sep 03, 2009 9:38 pm

- Location: Texas, USA

- Been thanked: 7 times

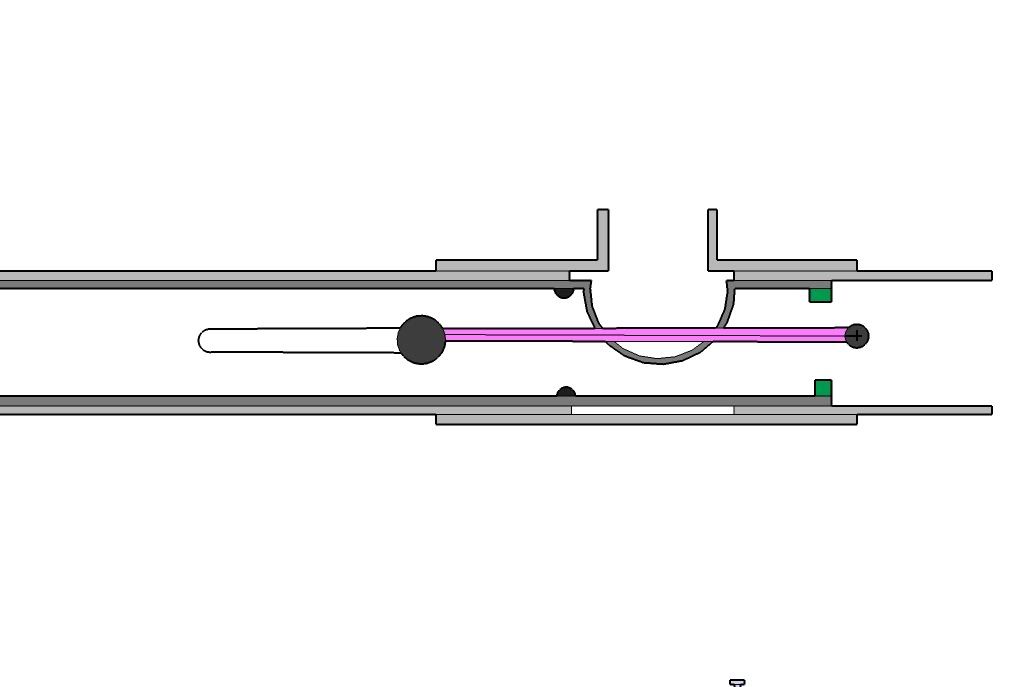

There is a small flow restriction at the beginning of the barrel before the mag port that give air some surface area to push on. The diagram is a very old one, not very similar to the actual design, but same concept. I'll have pictures of the true setup tomorrow. The bolt cycles a full three inches forward, so I may just need some o-rings, but I really hope I don't

- Gaderelguitarist

- Corporal

- Posts: 580

- Joined: Sat Aug 16, 2008 9:56 pm

- Location: Columbia, MD

- Contact:

I would think an o ring before and after the mag port would help.

so many muchness

- Lockednloaded

- Staff Sergeant

- Posts: 1566

- Joined: Thu Sep 03, 2009 9:38 pm

- Location: Texas, USA

- Been thanked: 7 times

Thats going to be tough, it'll have to be extremely low friction without deep grooves...

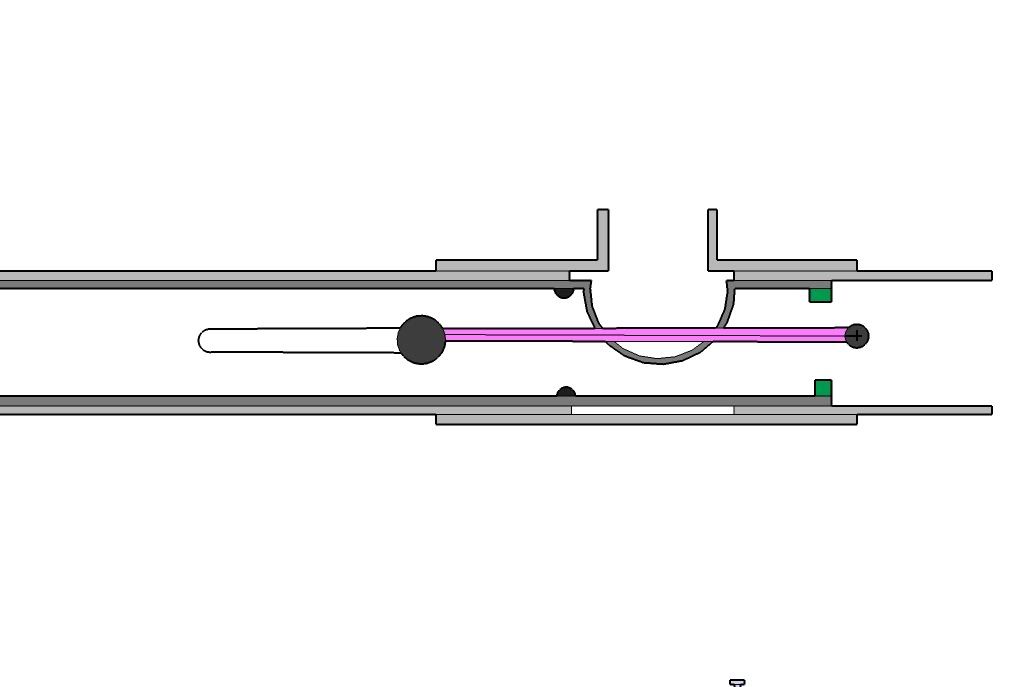

The actual design I've been using, I hope everything's clear

The actual design I've been using, I hope everything's clear

- POLAND_SPUD

- Captain

- Posts: 5402

- Joined: Sat Oct 13, 2007 4:43 pm

- Been thanked: 1 time

guns are just like women... they operate best when loaded from behind

that's just my personal opinion... also moving barrels are not always the best idea

that's just my personal opinion... also moving barrels are not always the best idea

Children are the future

unless we stop them now

unless we stop them now

- Lockednloaded

- Staff Sergeant

- Posts: 1566

- Joined: Thu Sep 03, 2009 9:38 pm

- Location: Texas, USA

- Been thanked: 7 times

There are better ways that have been sucessful, but I really like the blow-forward action. Think of it like JSR and his cartridges. He wanted flying brass, I want a gun that cycles like a bofors

- Gaderelguitarist

- Corporal

- Posts: 580

- Joined: Sat Aug 16, 2008 9:56 pm

- Location: Columbia, MD

- Contact:

Is that design to scale? or roughly so?

It's easy enough to understand. I just can't think of a reason why your mag doesn't feed when not airtight.

It's easy enough to understand. I just can't think of a reason why your mag doesn't feed when not airtight.

so many muchness

- Lockednloaded

- Staff Sergeant

- Posts: 1566

- Joined: Thu Sep 03, 2009 9:38 pm

- Location: Texas, USA

- Been thanked: 7 times

roughly to scale. The mag feeds, just ammo can make it past the detent. I need the detent to aim downwards, so its staying

- Gun Freak

- Lieutenant 5

- Posts: 4971

- Joined: Mon Jan 25, 2010 4:38 pm

- Location: Florida

- Been thanked: 8 times

Why don't you just use a smaller detent?

OG Anti-Hybrid

One man's trash is a true Spudder's treasure!

Golf Ball Cannon "Superna" ■ M16 BBMG ■ Pengun ■ Hammer Valve Airsoft Sniper ■ High Pressure .22 Coax

Holy Shat!

One man's trash is a true Spudder's treasure!

Golf Ball Cannon "Superna" ■ M16 BBMG ■ Pengun ■ Hammer Valve Airsoft Sniper ■ High Pressure .22 Coax

Holy Shat!

- Lockednloaded

- Staff Sergeant

- Posts: 1566

- Joined: Thu Sep 03, 2009 9:38 pm

- Location: Texas, USA

- Been thanked: 7 times

Its two pieces of electrical tape right now, I really can get much smaller. Also when I tested it without the detent, the tee mag was blown off and it double fed

- Gaderelguitarist

- Corporal

- Posts: 580

- Joined: Sat Aug 16, 2008 9:56 pm

- Location: Columbia, MD

- Contact:

At rest, is the mag port in the barrel to the left or right of the hole in the tee?

Nevermind

I took another look at the diagram. I think you should be fine with putting an o-ring in the Tee itself on the right side of the diagram. This would seal off your mag and prevent your problem. Make sure it's sized to the inner diameter of the pipe it's in rather than the barrel though since it will ride against your port.

Nevermind

I took another look at the diagram. I think you should be fine with putting an o-ring in the Tee itself on the right side of the diagram. This would seal off your mag and prevent your problem. Make sure it's sized to the inner diameter of the pipe it's in rather than the barrel though since it will ride against your port.

so many muchness

Create an account or sign in to join the discussion

You need to be a member in order to post a reply

Create an account

Not a member? register to join our community

Members can start their own topics & subscribe to topics

It’s free and only takes a minute

Sign in

-

- Similar Topics

- Replies

- Views

- Last post

-

- 15 Replies

- 5239 Views

-

Last post by jackssmirkingrevenge

-

- 3 Replies

- 1484 Views

-

Last post by jackssmirkingrevenge

-

- 5 Replies

- 4060 Views

-

Last post by jackssmirkingrevenge

-

- 2 Replies

- 2113 Views

-

Last post by bobgengeskahn

-

- 20 Replies

- 6329 Views

-

Last post by jackssmirkingrevenge