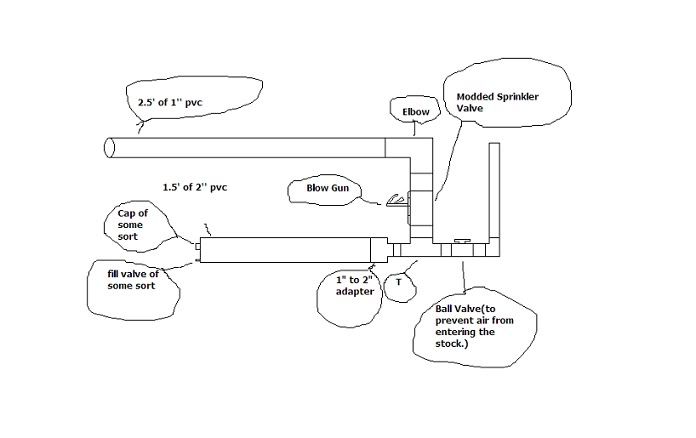

Heres My Plans. Finally

- MrCrowley

- Moderator

- Posts: 10078

- Joined: Fri Jun 23, 2006 10:42 pm

- Location: Auckland, New Zealand

- Been thanked: 3 times

Fill valve, if you have a bike pump, use a tyre valve which is called a schrader.

If you have a air compressor(excl 12v ones) you'll want a quick connect fitting. Don't ask search.

I suggest looking at some other pneumatics on the site for a better design, it doesn't look very comfortable, is an odd shape and it'd be hard to trigger.

Maybe something like this:

http://www.spudfiles.com/forums/viewtop ... tml#123690

Inlines are very easy to fire, are fairly accurate and comfortable.

The cap you'll need is a 2" PVC end cap, make sure ALL the fittings are pressure rated.

If you don't know how to identify pressure rated fittings, I suggest you do some more research. But they should have NSF-PW on them.

If you have a air compressor(excl 12v ones) you'll want a quick connect fitting. Don't ask search.

I suggest looking at some other pneumatics on the site for a better design, it doesn't look very comfortable, is an odd shape and it'd be hard to trigger.

Maybe something like this:

http://www.spudfiles.com/forums/viewtop ... tml#123690

Inlines are very easy to fire, are fairly accurate and comfortable.

The cap you'll need is a 2" PVC end cap, make sure ALL the fittings are pressure rated.

If you don't know how to identify pressure rated fittings, I suggest you do some more research. But they should have NSF-PW on them.

- Zen///

- Specialist 2

- Posts: 278

- Joined: Sat Oct 27, 2007 3:49 pm

- Location: In a foxhole sniping,Calgary, Canada

- Contact:

The Ball valve isn't nessasary you can use another "cap of some sort"

"Fill valve of some sort"= Schrader valve (tire valve)

REMEMBER TO USE PRESSURE RATED PARTS!!!

Edit: Awww MR.C beat me

BTW great idea Crowely

"Fill valve of some sort"= Schrader valve (tire valve)

REMEMBER TO USE PRESSURE RATED PARTS!!!

Edit: Awww MR.C beat me

BTW great idea Crowely

Last edited by Zen/// on Thu Nov 29, 2007 7:51 pm, edited 1 time in total.

Copper burst disk cannon

4000psi shot

The burst disk "rifle" (not rick roll)

Currently away playing ps3

4000psi shot

The burst disk "rifle" (not rick roll)

Currently away playing ps3

- paaiyan

- First Sergeant

- Posts: 2140

- Joined: Wed Dec 27, 2006 10:03 pm

- Location: Central Oklahoma

- Been thanked: 1 time

1. Figure out another way to make that stock. It's flimsy and that ball valve is worthless there.

2. Find a way to connect the barrel to the chamber for support, otherwise the torque from the shot might just blow out an elbow joint, we've seen it before.

3. You probably don't want a cleanout cap on the end there, get a regular cap for it.

4. Schrader valve's probably your best bet for filling the chamber.

EDIT: I must type slow or something, none of those other posts were there when I started.

2. Find a way to connect the barrel to the chamber for support, otherwise the torque from the shot might just blow out an elbow joint, we've seen it before.

3. You probably don't want a cleanout cap on the end there, get a regular cap for it.

4. Schrader valve's probably your best bet for filling the chamber.

EDIT: I must type slow or something, none of those other posts were there when I started.

"Who ever said the pen was mightier than the sword, obviously, never encountered automatic weapons."

-General Douglass MacArthur

Read my dog's blog - Life of Kilo

-General Douglass MacArthur

Read my dog's blog - Life of Kilo

- jackssmirkingrevenge

- Five Star General

- Posts: 26219

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 582 times

- Been thanked: 348 times

Try and put the sprinkler valve horizontal behind the barrel to avoid the dead space in the elbow.

hectmarr wrote:You have to make many weapons, because this field is long and short life

thats what i was going to do, but i screwed up, and i thought maube it'll work this way better, but it dont. i will attach the sprinkler to the barrel, then a short piece, the the elbow. or maybe a T thhen start the stock from there, and go arond, the down. i will try to redraw it soon.jackssmirkingrevenge wrote:Try and put the sprinkler valve horizontal behind the barrel to avoid the dead space in the elbow.

Create an account or sign in to join the discussion

You need to be a member in order to post a reply

Create an account

Not a member? register to join our community

Members can start their own topics & subscribe to topics

It’s free and only takes a minute

Sign in

-

- Similar Topics

- Replies

- Views

- Last post

-

- 15 Replies

- 3572 Views

-

Last post by starman

-

- 23 Replies

- 10037 Views

-

Last post by Jolly Roger

-

- 28 Replies

- 4875 Views

-

Last post by goathunter

-

- 16 Replies

- 4011 Views

-

Last post by watto

-

- 6 Replies

- 3026 Views

-

Last post by Technician1002